- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TFZD

-

Voltage:

-

110V,220V,380V,410V...

-

Dimension(L*W*H):

-

customizabled

-

Weight:

-

40 KG

-

Product name:

-

Vibrating Sieve

-

Keyword:

-

Vibratory Sieve

-

Motor:

-

Vertical Vibrating Motor

-

Material:

-

Carbon Steel/ Stainless Steel 304

-

Usage:

-

Separation Screening

-

Name:

-

Mining Vibrating Screen

-

Function:

-

Screening\separation\sorting\sieving

-

Layer(s):

-

1-5 Layers

-

Feature:

-

High Screening Efficiency

-

Mesh size:

-

2-500mesh

Quick Details

-

Type:

-

square

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

TFZD

-

Voltage:

-

110V,220V,380V,410V...

-

Dimension(L*W*H):

-

customizabled

-

Weight:

-

40 KG

-

Product name:

-

Vibrating Sieve

-

Keyword:

-

Vibratory Sieve

-

Motor:

-

Vertical Vibrating Motor

-

Material:

-

Carbon Steel/ Stainless Steel 304

-

Usage:

-

Separation Screening

-

Name:

-

Mining Vibrating Screen

-

Function:

-

Screening\separation\sorting\sieving

-

Layer(s):

-

1-5 Layers

-

Feature:

-

High Screening Efficiency

-

Mesh size:

-

2-500mesh

Product Overview

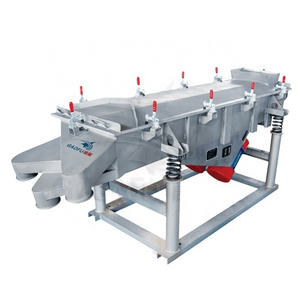

industrial salt calcium carbonate sieving machine Taoli sand screening machine vibrating screen

Square swing screen

is a type of artificial screening equipment that simulates the horizontal circular rotation of the screen body. This device can adjust the number and combination of various network layers according to customer needs. Due to its stable working state and no vibration during operation, this product has the technical characteristics of high output, high accuracy, long screen life, and low failure rate. For quartz sand, construction sand, oil fracturing sand, all kinds of ores, coke, ceramsite, plastic chemical particles and all kinds of metal powder, compared with the traditional screen machine, the output and fineness are greatly improved.

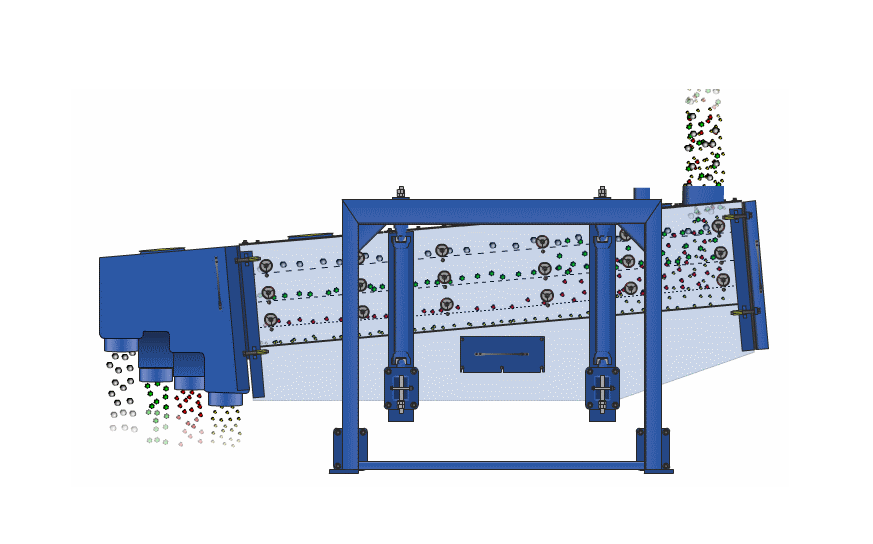

work principle

Working Principle

Product Parameters

|

Model

|

Screen Size

(m) |

Screening area

(m²) |

Power

(KW) |

Screen surface inclination

(°) |

Rotation frequency

r/min |

Screen box stroke

(mm) |

Number of layers

|

|

FYB 1036

|

1.0*3.6

|

3-27

|

3

|

5±3

|

180-260

|

25-60

|

1-9

|

|

FYB 1236

|

1.2*3.6

|

4-36

|

5

|

5±3

|

180-260

|

25-60

|

1-9

|

|

FYB 1536

|

1.5*3.6

|

5-45

|

5.5

|

5±3

|

180-260

|

25-60

|

1-9

|

|

FYB 2040

|

2.0*4.0

|

8-72

|

7.5

|

5±3

|

180-260

|

25-60

|

1-9

|

Features

1. Reasonable design, simple structure and stable operation;

2. The screen has a long service life, high screening accuracy, convenient and quick screen replacement, and silica gel balls are placed in each screen grid, with the function of screen cleaning, which can improve the screening efficiency;

3. The exciter unit is an integral box structure, which has the technical characteristics of simplicity, rationality, firmness,

stable design, and even transmission of exciting force.

4. Good sealing effect, low noise, no dust, and improved workshop working environment.

1. Reasonable design, simple structure and stable operation;

2. The screen has a long service life, high screening accuracy, convenient and quick screen replacement, and silica gel balls are placed in each screen grid, with the function of screen cleaning, which can improve the screening efficiency;

3. The exciter unit is an integral box structure, which has the technical characteristics of simplicity, rationality, firmness,

stable design, and even transmission of exciting force.

4. Good sealing effect, low noise, no dust, and improved workshop working environment.

Applicable industries

Quartz sand, fracturing sand, limestone, coke, ceramsite, stone powder, iron powder, copper powder, aluminum powder, zinc powder and other metal powders.

Processing Procedure

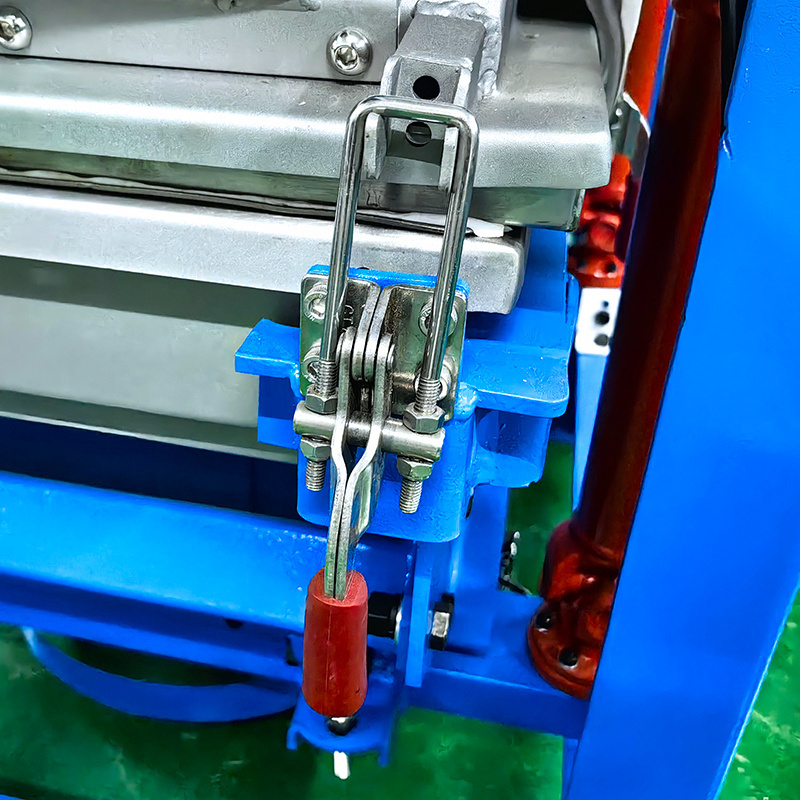

Detail show

Packaging&Shipping

After you place the order and pay the deposit in our company, we will start to arrange the production and contact the ocean

freight transportation agency to reserve the position. Two days before the end of production, you need to complete the final payment. Then, we will inform the ocean cargo transportation agent company that it is ready to come to the factory to pull the goods to the port. On the day of delivery, we will send you the factory video and pictures, and mark the corresponding English name of each product and product parts with a marker to prevent you from not knowing what each part is after receiving the goods.At the same time, we will put the English version of the product instructions in the cargo box. We generally select freight forwarders with preferential prices for customers to deliver goods for you. The shipping method can be FOB or CIF. You can also choose EXW , and then contact the goods agent company yourself. About the packaging method and the shipping method, if you have any different idea, welcome to contact us.

freight transportation agency to reserve the position. Two days before the end of production, you need to complete the final payment. Then, we will inform the ocean cargo transportation agent company that it is ready to come to the factory to pull the goods to the port. On the day of delivery, we will send you the factory video and pictures, and mark the corresponding English name of each product and product parts with a marker to prevent you from not knowing what each part is after receiving the goods.At the same time, we will put the English version of the product instructions in the cargo box. We generally select freight forwarders with preferential prices for customers to deliver goods for you. The shipping method can be FOB or CIF. You can also choose EXW , and then contact the goods agent company yourself. About the packaging method and the shipping method, if you have any different idea, welcome to contact us.

COMPANY PROFILE

Hot Searches