- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

According to your needs

-

Voltage:

-

According to your needs

-

Power:

-

According to your needs

-

Weight (KG):

-

35000

-

Raw material:

-

Bamboo bagasse Oil sludge Sawdust Rice hull Coconut shell Wood

-

Product name:

-

biomass carbonization machine

-

Final product:

-

biomass carbon

-

Advantage:

-

High efficiency Pollution-free Applicable to a variety of materials

-

Capacity:

-

1T/H,2T/H,3T/H,4T/H,5T/H,10T/H,20T/H ,50T/H

-

Carbonization time:

-

6-8 Hours

-

Carboniztion type:

-

Continuous Air Flow

-

Keywords:

-

Wood Charcoal Making Machine Biomass Carbonization Stove

-

Name:

-

Smokeless Wood Biochar Making Machine Biomass Carbonization Furnace

-

H2:

-

Wood Charcoal Making Machine Sawdust Biomass Carbonization Furnace

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XKJ GROUP

-

Effective Volume:

-

According to your needs

-

Dimension(L*W*H):

-

According to your needs

-

Voltage:

-

According to your needs

-

Power:

-

According to your needs

-

Weight (KG):

-

35000

-

Raw material:

-

Bamboo bagasse Oil sludge Sawdust Rice hull Coconut shell Wood

-

Product name:

-

biomass carbonization machine

-

Final product:

-

biomass carbon

-

Advantage:

-

High efficiency Pollution-free Applicable to a variety of materials

-

Capacity:

-

1T/H,2T/H,3T/H,4T/H,5T/H,10T/H,20T/H ,50T/H

-

Carbonization time:

-

6-8 Hours

-

Carboniztion type:

-

Continuous Air Flow

-

Keywords:

-

Wood Charcoal Making Machine Biomass Carbonization Stove

-

Name:

-

Smokeless Wood Biochar Making Machine Biomass Carbonization Furnace

-

H2:

-

Wood Charcoal Making Machine Sawdust Biomass Carbonization Furnace

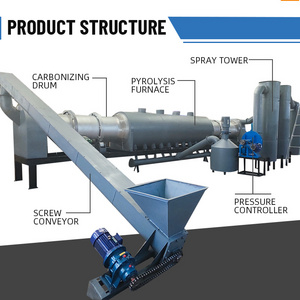

Charcoal making machine

The charcoal making machine is a machine that converts biomass such as coconut shell,

sawdust, wood, palm kernel shell, rice husk,as well as domestic garbage and sludge into

biochar in an oxygen-free atmosphere.

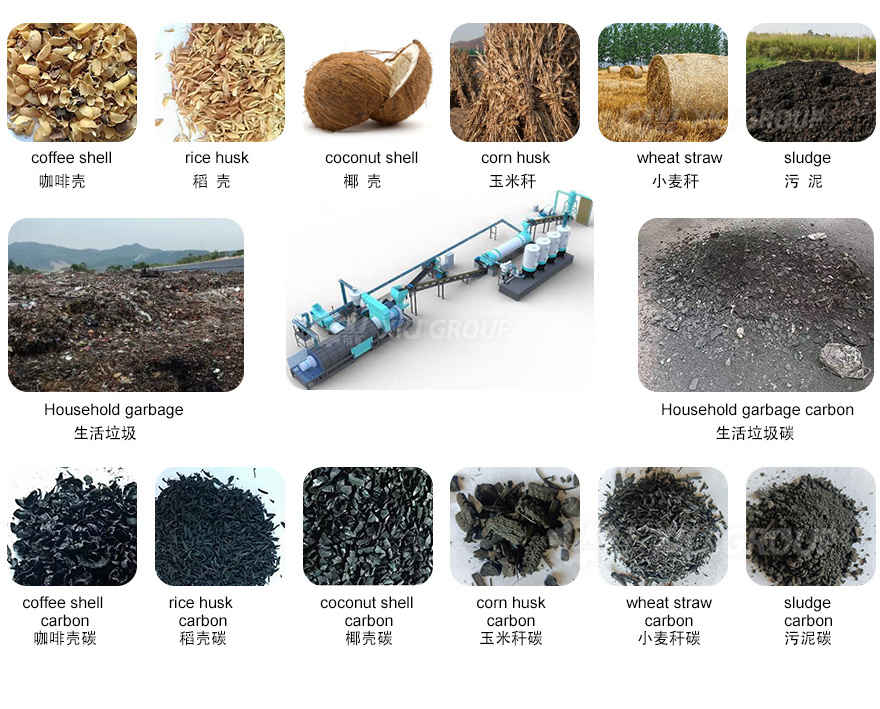

Available raw materials for charcoal making machine

♦All organic waste in nature.

♦

Biomass waste (wood chips, branches, sawdust, bamboo, etc); agricultural waste (rice husk/hull, coconut shell, palm kernel shell, olive shell, coffee shell, straws, bagasse); human waste; kitchen garbage (mostly fruit peels); animal waste; etc.

♦

Municipal solid waste.

♦

Sewage sludge.

♦ The raw materials are carbonized and pyrolyzed into bio charcoal in a high-temperature and anaerobic environment. The detailed biochar production process of our biochar equipment is as follow:

♦ Feed the raw materials by a constant weight feeder into the carbonization host. If the water content of the materials is more than 25%, you must use a drying host to dry them at first. The perfect water content is below 15% in order to make sure a high quality of biochar.

♦ Preheat the carbonization host while feeding for about 30 minutes. During the pre-heating, the combustible gas will be generated and then recycled into fuel to supply heat for the carbonization host.

♦

The process of carbonization and pyrolysis of biomass waste happens as the temperature rises. Through desulfurization and dedusting, the clean biochar will be discharged. The whole process lasts about 15 min to 20 min.

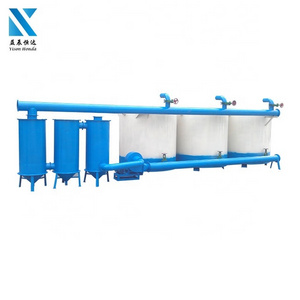

♦

The flue gas/residual hot smoke will go through a strict filtering system in the water spraying tower with the functions of de-dusting, water washing, ceramic ring absorption and activated carbon absorption. Finally, it will be discharged outwards safely, meeting the EU Environmental Protection and Emission Standard.

Our company was founded in 1956,till now has more than 60 years of development history, since in 1996 changed to joint-stock co., LTD., has five standard heavy industrial workshops ,covers an area of 200,000 square meters, subsidiary company have Henan Xingyang Mining Machinery CO., LTD, Tibet Branch, Xinxiang casting plant, Xinxiang processing factory. We have devoted ourselves all the time to research and develop new products and technologies, we can provide customers with ore-dressing test, process work flow design, equipment manufacture, on-site installation and debugging,mining operations, mining stuff procurement management service etc EPC services.