- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

300L

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V 380V, 220V.380V/customized

-

Dimension(L*W*H):

-

customized

-

Power (kW):

-

5.5 kW, 1.1-11

-

Product name:

-

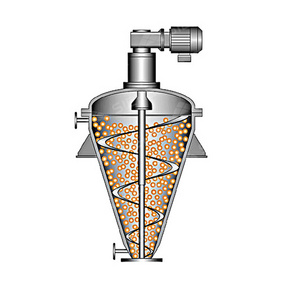

Conical screw mixer

-

Frequency:

-

32-65r/min

Quick Details

-

Barrel Volume (L):

-

100-30000

-

Max. Loading Volume (L):

-

20000 L

-

Range of Spindle Speed(r.p.m):

-

44 - 175 r.p.m, 44- 175 r.p.m

-

Max. Loading Capacity:

-

300L

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V 380V, 220V.380V/customized

-

Dimension(L*W*H):

-

customized

-

Power (kW):

-

5.5 kW, 1.1-11

-

Product name:

-

Conical screw mixer

-

Frequency:

-

32-65r/min

This series of machine is one high efficient mixing equipment, which is widely applied in mixing solid-solid status materials (powder-powder), as well as mixing solid-liquid status materials (powder materials added with liquid materials) from the chemical, fertilizer, dye, metallurgy, mine, food, monosodium glutamate, fodder industries.

This equipment is adaptable and flexible to the mixture, cannot cause heat sensitive materials overheated and cannot grate partical materials.

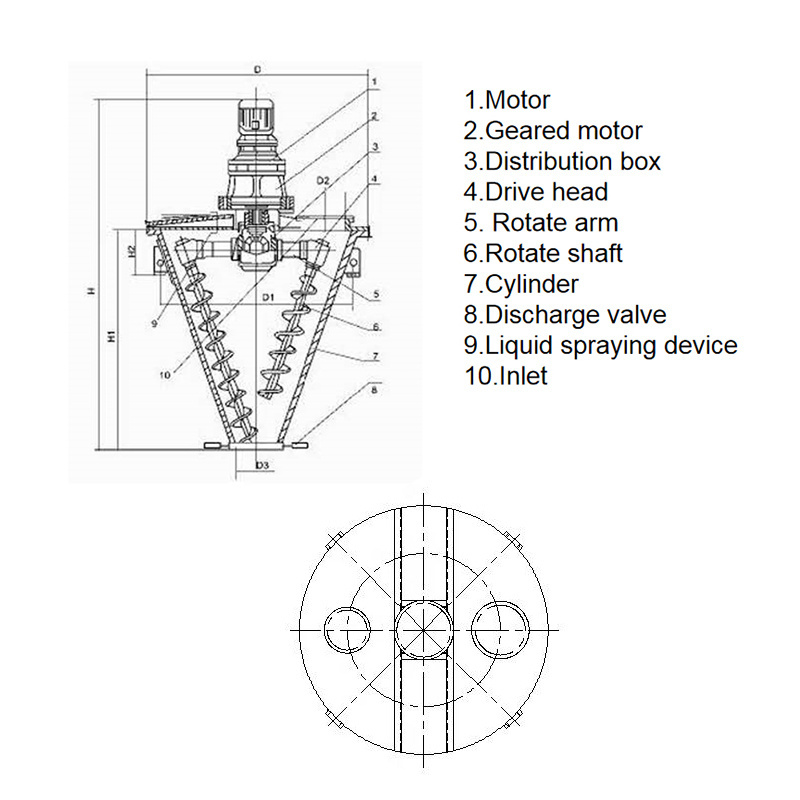

Working Principle

the machine is mainly composed of mixing tank, spiral agitating vane and transmission parts. There are two layers of spiral agitating vane. The outside vanes accumulate the material from side to center, while the inner vanes separate the material from center to side. So that material will mix to each other in convective mixing inside the tank. It’s high

Main Technology Parameters:

|

Model

|

VBDS-180

|

VBDS-300

|

VBDS-500

|

VBDS-1000

|

VBDS-2000

|

VBDS-3000

|

VBDS-4000

|

|

Power(kw)

|

1.1

|

1.1

|

2.2

|

4

|

7.5

|

11

|

11

|

|

Capacity (kg/batch)

|

40

|

60

|

100

|

200

|

400

|

600

|

800

|

|

Total volume(m³)

|

0.18

|

0.3

|

0.5

|

1

|

2

|

3

|

4

|

|

Mixing time(min)

|

4-8

|

6-10

|

6-10

|

6-10

|

6-10

|

6-10

|

6-10

|

|

Speed(r/min)

|

12

|

12

|

12

|

10

|

10

|

8

|

8

|

1.Mixing Efficiency: Various mixing screw configurations, including single long, double (one long and one short), or triple (two short and one long symmetrically arranged), are available to achieve optimal mixing outcomes.

2.Temperature Control: External jackets surrounding the mixer barrel facilitate precise temperature regulation through the circulation of hot or cold media such as water, steam, or heat transfer oil.

3.Liquid Incorporation: Liquid mixing is facilitated by a spray pipe positioned at the intermediate shaft, connected to atomizing nozzles, ensuring efficient blending of liquid additives with dry materials.

4.Custom Pressure-Resistant Design: Customized pressure-resistant cylinder covers and reinforced cylinder bodies are designed to withstand positive or negative pressure conditions, enhancing safety and ease of cleaning.

5.Versatile Feeding Options: Feeding methods include manual, vacuum, or mechanical conveyance. Negative pressure chambers equipped with hoses prevent material residue and contamination during the feeding process.

6.Efficient Discharge Mechanisms: Standard discharge mechanisms feature a plum blossom-shaped "dislocation valve" at the base of the mixer's primary screw, minimizing dead zones. Additional options such as butterfly valves, ball valves, or star dischargers are available to suit specific user preferences.

Control panel

Feed gate

Feed inlet

Electric motor

Feed

outlet

1.

Suitable for the powder, the particle, add the lubricant, bind the mixing of spices, etc...

2. Can join the vacuum system with enter the material automatically, or connect oscillator by automatic granulation take shape and

operate airtight.

3. Enclose the time-recorder and automatically control and mix time

2. Can join the vacuum system with enter the material automatically, or connect oscillator by automatic granulation take shape and

operate airtight.

3. Enclose the time-recorder and automatically control and mix time

Henan vibrate Machinery is a production of food, chemical equipment enterprises, located in Henan Xinxiang City. We design custom solutions for the production, washing, cutting, meat processing, packaging and filling of vegetables, spices, meat, liquids, powders and pellets in many industries such as food, pharmaceutical, plastics, chemical, etc. Our main products include: packaging machines, filling machines, cleaning machines, cutting machines, meat processing machines and related products. the company has passed iso9001 quality management system certification and SGS certification, and all products have passed CE certification.

At present, the products have been exported to 96 countries and regions.

We also have in-depth cooperation with local agents in key markets such as Indonesia, Malaysia, Singapore, Thailand, India, Vietnam, Brazil, Australia, France, United Kingdom, Hungary, etc., to provide localized after-sales service and technical support.

Our Certification

Q: 1. Are you a manufacturer, trading company or third party?

A: We are a manufacturer, located in the high-tech zone of Xinxiang City, Henan Province, China. You are warmly welcome to visit our company.

Q:2. What is your minimum order quantity and can you send me samples?

A: Our MOQ is 1 set, because our products are mechanical equipments, so it is difficult to send you samples, if you have any questions about the products, please feel free to contact us for more details, we will be happy to provide you with more information, such as specifications, videos and so on.

Q:3. How does your factory perform quality control?

A:

(1) All raw materials we use are environmentally friendly.

(2) Skilled workers pay attention to every detail during production and packaging.

(3) The quality control department specializes in the quality of each process.36 Over the years, we continue to introduce advanced technology and provide high quality products, and our products are also widely exported to many countries, such as Russia, Middle East, Africa, Southeast Asia, and the European Union, and we have won a high reputation among our customers.

Q: 4. What is the delivery time of your machines?

A: Generally speaking, the delivery period of our machines is about 30 days, and the customized machines will be delivered according to the negotiation with customers.

Q: 5. How about after-sales service?

A:(1) TM is online 24 hours a day, also can be contacted by email, skype, MSN, whatsapp etc.

(2) Problem solving by video/picture.

(3) One year warranty for spare parts replacement. If you encounter any other problems, please feel free to contact us.

If you meet any other questions, please feel free to contact us.

click here.

Hot Searches