- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3PH 380V~415V 50HZ/60HZ

-

Dimension(L*W*H):

-

2450*1800*2060

-

Weight:

-

1320 KG

-

Power:

-

150000W

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Refrigerant:

-

R22/R407C

-

Compressor type:

-

Hermetic-scroll

-

Condenser:

-

Aluminum Finned coil+low noise axil fan

-

Evaporator:

-

Shell & tube

-

Application:

-

extruder & injection machine

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Condition:

-

NEW100%

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HERO-TECH

-

Voltage:

-

3PH 380V~415V 50HZ/60HZ

-

Dimension(L*W*H):

-

2450*1800*2060

-

Weight:

-

1320 KG

-

Power:

-

150000W

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Refrigerant:

-

R22/R407C

-

Compressor type:

-

Hermetic-scroll

-

Condenser:

-

Aluminum Finned coil+low noise axil fan

-

Evaporator:

-

Shell & tube

-

Application:

-

extruder & injection machine

-

Marketing Type:

-

Ordinary Product

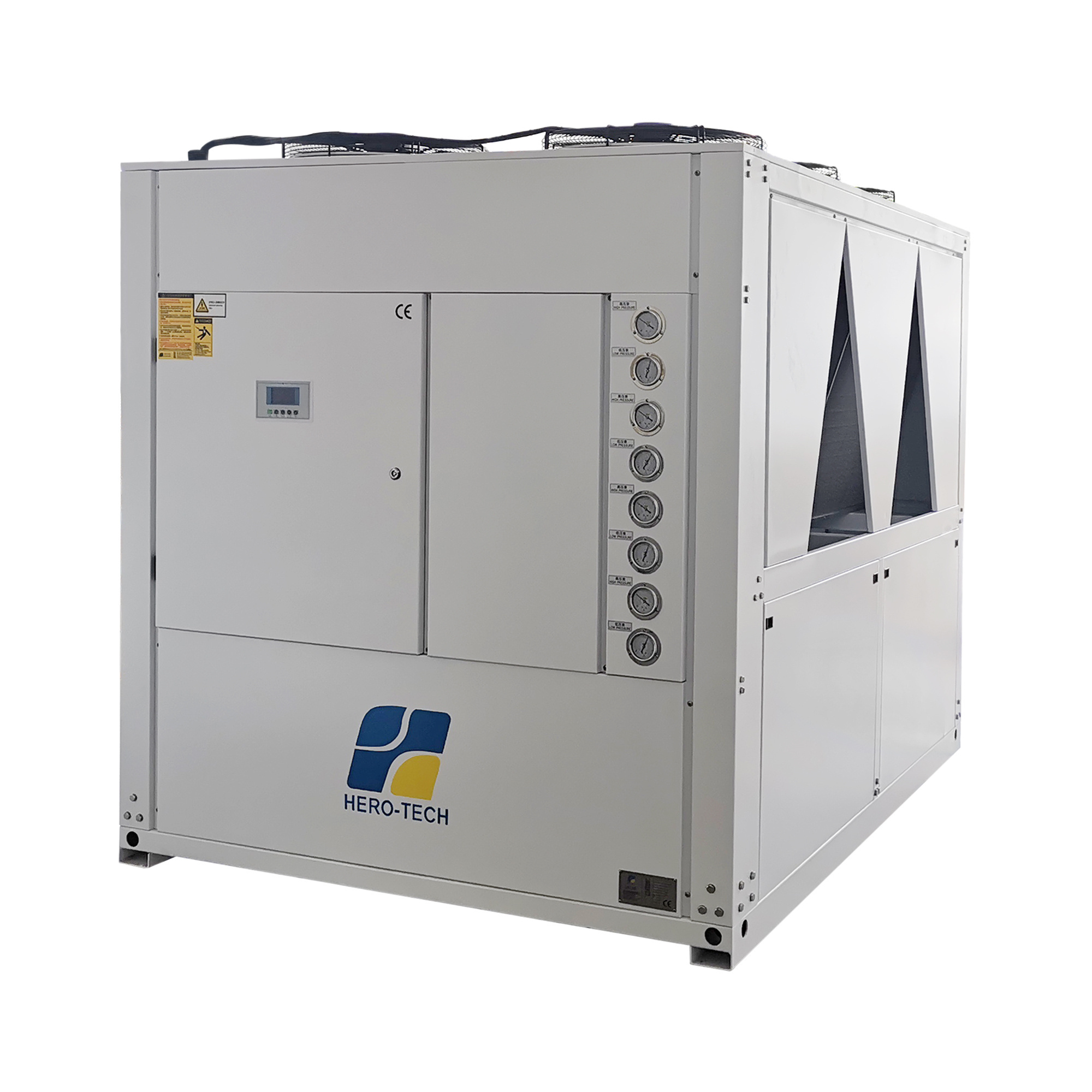

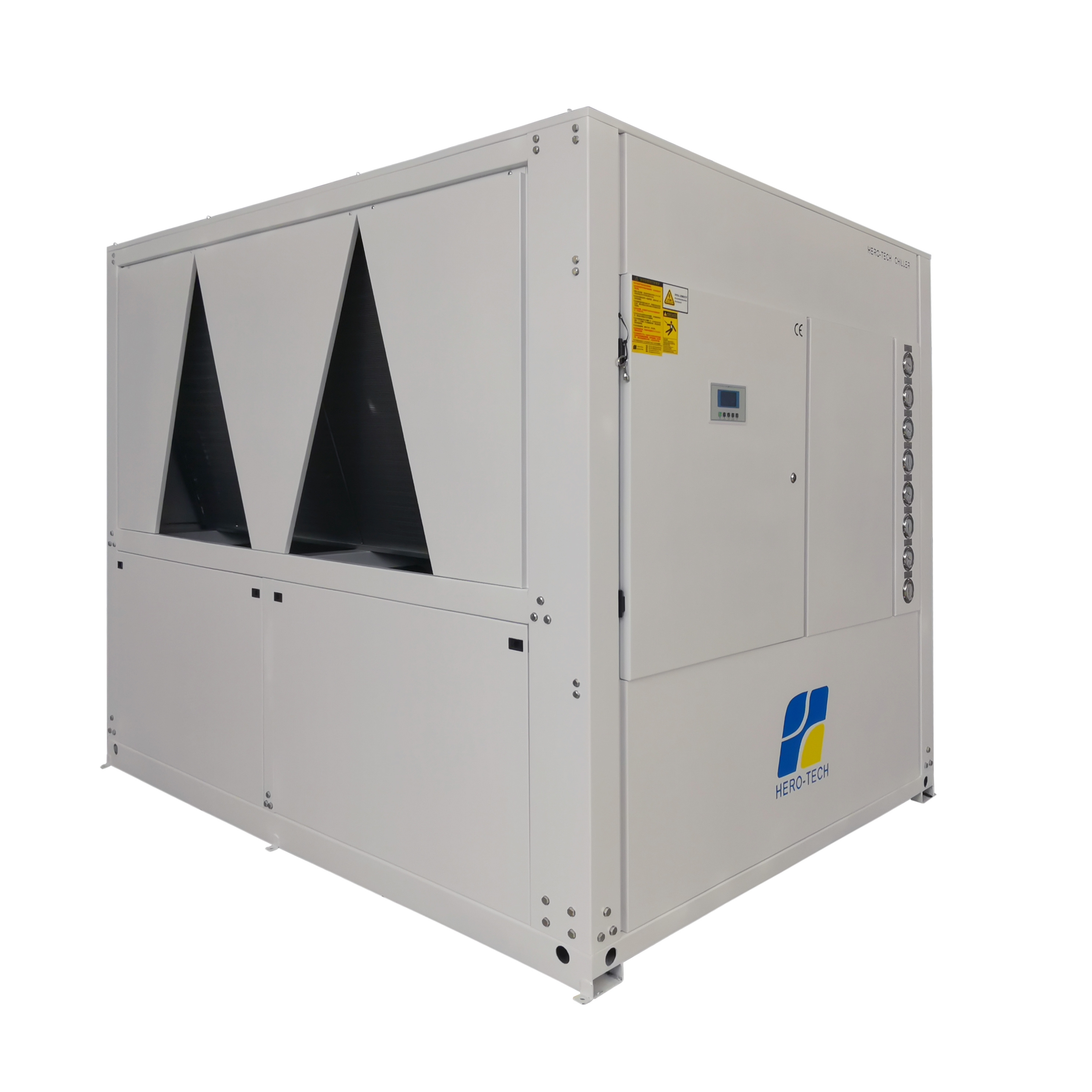

HTI-A series industrial chiller is mainly applied in Plastic & Rubber industry; It can accurately control the molding temperature and shorten the molding cycle, increase the product quality and improve t he production efficiency.They are also widely used in Metal working, Mechanical & Engineering, Chemical & Pharmaceutical, Food &Beverage, Laser, Electronics industry, Textile, Electroplate, Semi-conductor testing, Water jet, Vacuum coating,Construction and Military.

|

Model

|

|

|

HTI-50AF

|

||

|

Nominal Cooling Capacity@7℃

|

|

Kcal/h

|

109220

|

||

|

|

|

KW

|

127

|

||

|

Nominal Cooling Capacity@12℃

|

|

Kcal/h

|

129000

|

||

|

|

|

KW

|

150

|

||

|

Max Power Consumption

|

|

KW

|

41.34

|

||

|

Power Source

|

|

|

3PH 380V/50HZ

(3PH 220V/380V/440V 60HZ) |

||

|

Refrigerant

|

Type

|

|

R22/R407C

|

||

|

|

Control

|

|

Thermostatic expansion valve

|

||

|

Compressor

|

Type

|

|

Hermetic Scroll

|

||

|

|

Max Power

|

KW

|

8.76*4

|

||

|

Condenser

|

Type

|

|

finned copper tube + low noise axial fan

|

||

|

|

Fan Motor

|

KW

|

0.55*6

|

||

|

|

Air Volume

|

m3/h

|

50000

|

||

|

Evaporator

|

Type

|

|

Shell and tube+SS tank

or SS coil in SS tank |

||

|

|

Coolant Flow

|

m3/h

|

21.9

|

||

|

|

Tank Volume

|

Litre

|

400/580

|

||

|

|

Inlet and Outlet

|

Inch

|

3

|

||

|

Pump

|

Power

|

KW

|

3.7

|

||

|

|

Head

|

m

|

20

|

||

|

Unit Protection Modules

|

|

Motor Overload, High&Low Pressure, Chilled Water Over Temperature, Flow switch, Tank Level switch, phase protection, anti-freezing

protection |

|

||

|

Dimension

|

Length

|

mm

|

2450

|

||

|

|

Width

|

mm

|

1800

|

||

|

|

Height

|

mm

|

2060

|

||

|

Weight

|

|

KG

|

1320

|

||

* Chilled water supply/return temperature: 12℃/17℃

* Cooling air inlet/outlet temperature: 30℃/38℃

* Condensing temperature 45℃, evaporating temperature 7℃;

* Chiller should be used under max 40℃ ambient temperature.

* R407C, R410A, R134A for option.

We reserve the right to modify the specifications without further notice.

Main Features

Adopted world famous brand compressors and high efficiency condenser and evaporator, ensure high cooling efficiency, low energy consumption, low noise and long service life;

adopted aluminum fin/copper tube type condenser, easy for cleaning and installation;

5C to 35C optional temperature range;

R22 charged, CFC free type R407C, R410A for option, R134A, r404A for special condition, high cooling efficiency;

Over sized evaporator and condenser ensure the chiller unit running under 45C high ambient temperature;

Microcomputer control system offering accurate temperature stability within ±1℃;

Low noise and big volume air blower;

Standard equipped Iron pump, stainless steel or high lift pump for option;

Multi-protection devices ensure the chiller unit running safely;

The innovative evaporator-in-tank configuration ensures a steady water temperature offered, as the evaporator also cools the tank itself, reduces ambient heat gain, and increases the efficiency.

Pre-Sales Service

* Inquiry and consulting support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.