- Product Details

- {{item.text}}

Quick Details

-

Formaldehyde Emission Standards:

-

E0

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SGH

-

Model Number:

-

1220x2440mm

-

Product name:

-

bent plywood, flexiblewood

-

Face/back:

-

commercial plywood

-

Thickness:

-

1.8mm-18mm

-

Moisture:

-

8%-14%

-

Core:

-

poplar basswood

-

Glue:

-

E0

-

Type:

-

bending wood

-

name:

-

bent plywood chair

-

Material:

-

poplar wood

-

Keywords:

-

plywood

Quick Details

-

Warranty:

-

3 years

-

Project Solution Capability:

-

graphic design, NONE

-

Application:

-

Office Building

-

Formaldehyde Emission Standards:

-

E0

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SGH

-

Model Number:

-

1220x2440mm

-

Product name:

-

bent plywood, flexiblewood

-

Face/back:

-

commercial plywood

-

Thickness:

-

1.8mm-18mm

-

Moisture:

-

8%-14%

-

Core:

-

poplar basswood

-

Glue:

-

E0

-

Type:

-

bending wood

-

name:

-

bent plywood chair

-

Material:

-

poplar wood

-

Keywords:

-

plywood

|

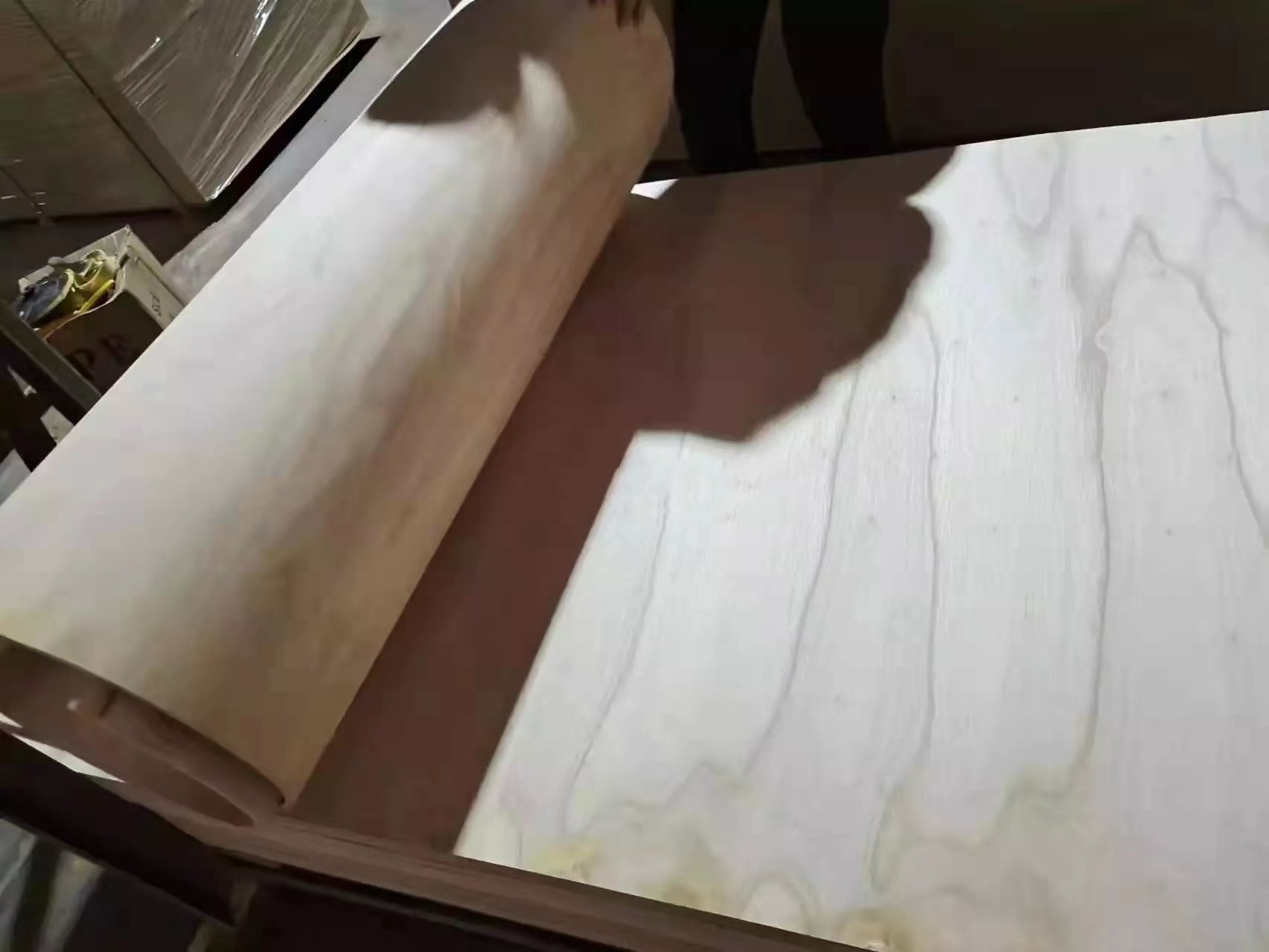

Flexible Plywood/ Bending Plywood/Bendable Plywood Plywood is a sheet material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers. Having their wood grain rotated up to 90 degrees to one another.

|

|

|

|

| Face/Back | Okoume, bintangor, poplar, birch, pine, pencil cedar, keruing, agathis, meranti, hardwood, etc. |

| Core | Poplar, hardwood, eucalyptus, okoume, birch, pine, combi, etc. |

| Glue Grade | BB/BB, BB/CC, CC/CC, CC/DD,DD/EE, etc. |

| Glue | E0, E1, E2, Melamine or WBP |

| Size | 1220x2440mm, 1250x2500mm, or as your request |

| Thickness | 1.8~18mm |

| Thickness Tolerance | +/-0.2mm (thickness<6mm), +/-0.3~0.5mm (thickness≥6mm) |

| Density | 500~680kg/m3 |

| Technical Parameters | Moisture Content : 8%~15% |

| Water Absorption : ≤10% | |

| Modulus of Elasticity : ≥5000Mpa | |

| Static Bending Strength : ≥30Mpa | |

| Surface Bonding Strength : ≥1.60Mpa | |

| Internal Bonding Strength : ≥0.90Mpa | |

| Screw Holding Ability : face ≥1900N; Edge ≥1200N | |

| Usage | Usage adequate for making furniture or chair |

| Delivery Time | Within 7 days after received deposit |

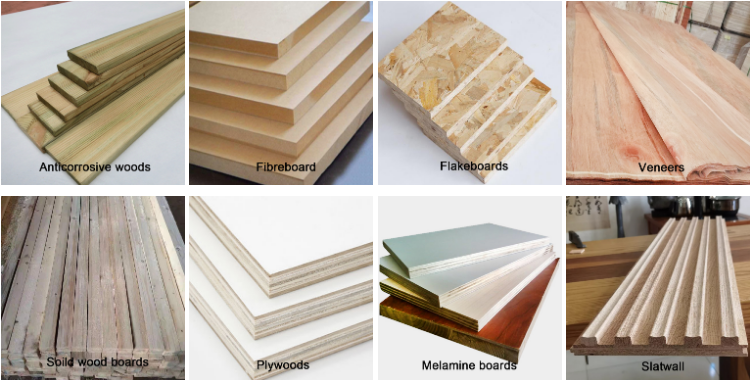

Here are some pictures to help you have a specific view about our particle board:

the face/back of bent plywood

Different thickness of plywood

Different core of plywood

knots pine plywood

commercial plywood

| OKOUME PLYWOOD | BINTANGOR PLYWOOD |

birch veneer plywood

larch veneer plywood

radiate pine plywood

film faced plywood

It is widely used for furniture, office table and interior decoration,etc.

| used for chair arm, chair leg, chair seats and backs | used for plate |

| king | Inter packing:0.2mm plastic |

| Ourter packing:bottom is pallets, covered with plastic film,around is carton or plywood, strenghthen by steel or iron 3*6 | |

| Quantity | 20GP : 8pallets/21M3 |

| 40GP : 16pallets/42M3 | |

| 40HQ : 18pallets/53M3 | |

| Minimum Order | 1*20GP |

| Payment | TT or L/C at sight |

| Delivery Time | 3~15 days receiving deposit or original L/C at sight |

| We have professional document and shipping department to provide the best service. |

| loose packing | pallet packing |

1. Selection&Gradign ---- 2. Veneer Machine Joint ---- 3. Veneer Gluing ---- 4. Core Assembled ---- 5. Cold Pre-pressing ---- 6. Hot Pressing ---- 7.Sanding ---- 8. Base Board Gluing ---- 9.Faced Veneer ----10. Hot Press for Veneer ---- 11. Cutting edge ---- 12. Polishing ---- 13. QC Slecting ----14. Edge Saaling ----15. Packing ----16. Loading

1. Strict QC Inspection

2. Certificate - Alibaba Verified Supplier

3. Exhibition

4. Good Service

4-1. I will reply within 2 hours

4-2. I am patience to any questions

4-3. I am also good at find solution to solve problem

5. Best Quality Reply from Customer