- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HAIXING

-

Voltage:

-

380v,50Hz,3 phase

-

Power:

-

15kw, 8.5kw

-

Dimension(L*W*H):

-

5.1*1.72*1.47m

-

Weight:

-

6500 kg

-

Warranty:

-

2 Years

-

Product name:

-

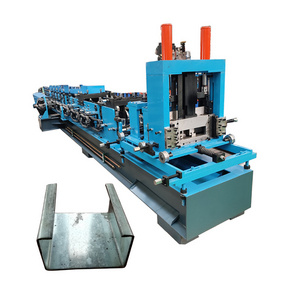

c purlin roll forming machine

-

Motor Brand:

-

Panasonic, Mitsubishi, Schneider,Siemens,Detal

-

Raw material:

-

Cold roll strip, gi strip

-

Control system:

-

PLC control system

-

Usage:

-

Produce C Z purlin panel

-

Cutting type:

-

Automatic Hydraulic Cutting/Flying saws cutting

-

Material of rollers:

-

High 45# forge steel

-

Raw material thickness:

-

0.8mm-3mm

-

Installation cost:

-

low cost

-

Feature:

-

Low Noise

Quick Details

-

Marketing Type:

-

New Product 2023

-

Work Pressure:

-

235---550Mpa

-

Production Capacity:

-

10-25m/min

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HAIXING

-

Voltage:

-

380v,50Hz,3 phase

-

Power:

-

15kw, 8.5kw

-

Dimension(L*W*H):

-

5.1*1.72*1.47m

-

Weight:

-

6500 kg

-

Warranty:

-

2 Years

-

Product name:

-

c purlin roll forming machine

-

Motor Brand:

-

Panasonic, Mitsubishi, Schneider,Siemens,Detal

-

Raw material:

-

Cold roll strip, gi strip

-

Control system:

-

PLC control system

-

Usage:

-

Produce C Z purlin panel

-

Cutting type:

-

Automatic Hydraulic Cutting/Flying saws cutting

-

Material of rollers:

-

High 45# forge steel

-

Raw material thickness:

-

0.8mm-3mm

-

Installation cost:

-

low cost

-

Feature:

-

Low Noise

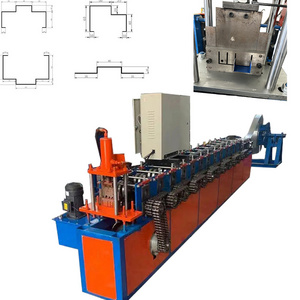

c purlin roll forming machine's description

| c purlin roll forming machine's technical parameters: | |

| Length of the main part | About 5.1*1.72*1.47m |

| Weight of main part | About 6.5 ton |

| Voltage | 380V/50HZ 3Phase (as customer`s request) |

| Main body | Tower structure |

| Wodrking speed | 0-25m/min (Adjustable) |

| Thickness of material | 0.8-3mm |

| Width of material | 130-600mm |

| Material of rollers |

45# steel,

GCr12MoV (SKD11) Aluminium processing after quenchin HRC58-62 °C, Chrome surface hard chromium painted. |

| Material of shafts | 45# steel |

| Diameter of shafts |

45#Aluminium-processing , diameter of axle=40mm(or depending on design) |

| Number of rollers: | 12 rollers(or depending on design) |

| Main power | 5.5kw |

| Cutting&Hydraulic | Hydraulic cutting & Flying saws cutting |

| Hydraulic motor power | 3kw |

| Hydraulic Pressure | 12MPa |

| C utting drive | Decelerating motor + Chain drive gear all by high-frequency |

| Control System | PLC system: Mitstubishi, Panasonic,Detal,Siemens,Schneider |

| length torlerance | +/-1.5mm |

| Effective width | B etter as your drawing or from our designer |

| Package of machine | Waterproofing membrane, standard export packing in 1*20GP container |

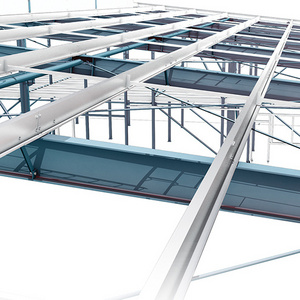

This roll forming machine provides significant improvements over other light gauge steel trusses currently available. Flexibility and design advantages allow architects, engineers, contractors and owners' exceptional versatility and performance characteristics not available with any other type of truss material.Our machine could update with the fashio for providing new design increases material efficiency, ease of fabrication, simplicity of erection, and improved safety of material handling. Nomatter for running business or for big construction, this machine will be good helper for you.

Our machine supports material thickness from 0.4-4mm light gauge steel truss with the full engineering technicaldata/specification. Designed and pre-engineered by experienced truss specialists using only the very latest software. Normally our machine could make truss for Indian, Australia, Egypet and other countries. The shapes of the trusss are like furring hat shape, U shape, C shape, L shape and others.

c purlin roll forming machine's description

|

Control system we use Panasonic, Siemens, Schneiderand other imported PLC control, we will strictly check every detail of the device. Performance protection device itself, but also to avoid artificial injuries. Feature : 1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime. 2. Other electric element are Delta 3. Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety. |

|

|

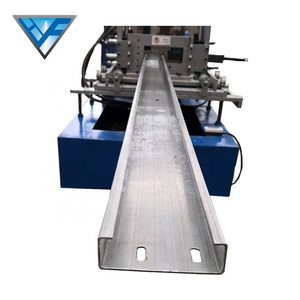

c purlin roll forming machine Shanghai motor applies force super-brand, quality and after-sales we have fully guaranteed |

|

Roller: Material of rollers: GCr12MoV Material of shafts: 45# steel with tempering Diameter of shafts: 40mm Number of rollers : 10 rollers Main power: 3kw No.1:We roller on each piece of machine is the use of 45 # steel No.2:Qenched for each roller, the roller increases the hardness and long service life No.3:And the use of plating technology roller surface treatment to improve the equipment of the main performance. |

|

|

Feature : Ensure stability, precision and cutting speed Function : Automatic cutting controlled by PLC It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: Gcr12MoV quenched Power supply : hydraulic power Frame : Pillar style with rack & pinion system Stroke switch : non-contact photoelectric switch |

|

|

Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron. |

|

c purlin roll forming machine's advantages

| 1 | Professional: rich experience in product and export process! |

| 2 | Low price:Save your money from every part! |

| a. Low labor cost; | |

| b. Convenient transportation; | |

| c. Complete supporting industries. | |

| 3 | PLC:Ensuring high accuracy and easy to operate! |

| Full Automatic: Just input length of the sheets and numbers of the piece you need, then the machine |

| c purlin roll forming machine's introducation and feature | |

| 1. | the main parts: 1) roll forming machine 2)molding press 3)cutting machine 4)PLC computer control 5)hydraulic system. |

| 2. | The machine is stable,no noise,no shake. |

| 3. | Controlling by computer, PLC display, operation is easy, running is steady and reliable,endurable |

| 4. | cutting machine is characterized by stable driving, easy operation. |

| 5. | hydraulic system use the CDF-10 hydraulic pump, long operating life,no noise. |

| 6. | material: galvanized,colored steel or aluminum coil |

| 7. | We can make and design the kinds of roll forming machine according to customer's request. |

c purlin roll forming machine's application

Packing and shipping

- Container packing of the line suitable for overseas shipping

- The subject can be loaded in one 40 GP container.

- Packaging style: Naked and covered by plastic film, spare parts and some small parts packed in box

- Container packing of the line suitable for overseas shipping

- Take the EUROPEAN quality standard;

- Choose the best material and components.

- Rich-xxperienced exports and top international sales to care your needs.

- Offer the highest quality but the best price in prevailing market.

- Customize for you.

- Our engineers accompanied the test machine until the customer satisfaction

- Our engineers free of charge for customer training guide customers to operate and maintain equipment

- Customers can ask engineers to client countries for machine installation and commissioning,clients pay the fleight cost and the cost of our engineer (usd80/day/person)