1. Water Supply Systems: Dual plate check valves are widely used in water distribution networks to prevent backflow and maintain the desired flow direction in pipes.

2. Oil and Gas Industry: In pipelines carrying oil, gas, or other hydrocarbons, dual plate check valves help prevent reverse flow and protect equipment from damage.

3. Chemical Processing: Dual plate check valves are used in chemical plants to control the flow of corrosive fluids and prevent backflow, ensuring safety and operational efficiency.

4. HVAC Systems: Heating, ventilation, and air conditioning systems utilize dual plate check valves to regulate fluid flow and prevent unwanted reverse flow in piping networks.

5. Power Generation: Dual plate check valves play a crucial role in power plants by maintaining the proper flow direction of cooling water, steam, and other fluids to ensure efficient operation.

6. Wastewater Treatment: Dual plate check valves help to manage the flow of wastewater in treatment plants, preventing contamination and maintaining operational integrity.

7. Marine Applications: These valves are used in marine systems, such as shipbuilding and offshore platforms, to control flow direction in seawater systems and ballast tanks.

8. Mining Industry: Dual plate check valves are employed in mining operations to control the flow of slurries, chemicals, and water, protecting pumps and equipment from damage.

9. Fire Protection Systems: Fire suppression systems utilize dual plate check valves to ensure the one-way flow of water or fire-fighting agents in sprinkler systems and hydrants.

10. Industrial Processes: Various industrial processes, such as food and beverage manufacturing, pharmaceutical production, and pulp and paper mills, rely on dual plate check valves for fluid control and safety.

Check valve (Retention valves) function:

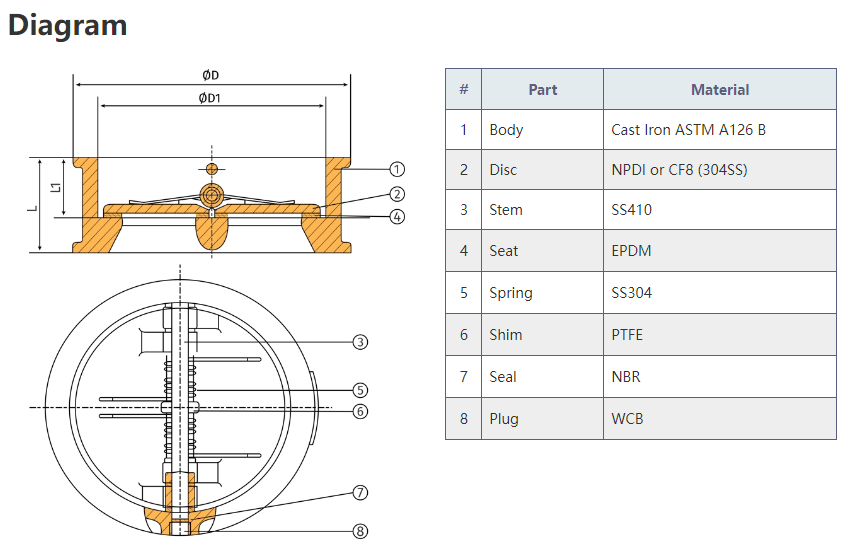

1. One-Way Flow Control: When fluid flows in the forward direction (from inlet to outlet), the pressure of the fluid opens the dual plates, allowing the fluid to pass through the valve.

2. Preventing Backflow: In the event of a reversal in flow direction or a decrease in pressure downstream, the dual plates quickly close under the force of gravity and a spring-loaded mechanism. This closure prevents the backflow of fluid, maintaining the desired flow direction in the pipeline.

3. Minimizing Pressure Drop: The streamlined design of dual plate check valves helps to minimize pressure drop across the valve, ensuring efficient flow performance and operational reliability.

4. Quick Response: Dual plate check valves are known for their fast response time in closing when there is a change in flow direction, reducing the risk of water hammer and pipe damage.

5. Automatic Operation: The operation of dual plate check valves is automatic and does not require external power or control. The mechanism responds to changes in fluid flow direction and pressure independently.

6. Compact Design: Dual plate check valves have a compact design, making them suitable for applications where space is limited or where a lightweight valve solution is preferred.

7. Reliable Seal: The dual plates in the valve provide an effective seal against backflow, minimizing leakage and ensuring system integrity.

8. Low Maintenance: Due to their simple construction and fewer moving parts, dual plate check valves are generally low maintenance components, offering long-term reliability and cost-effectiveness.

2. Preventing Backflow: In the event of a reversal in flow direction or a decrease in pressure downstream, the dual plates quickly close under the force of gravity and a spring-loaded mechanism. This closure prevents the backflow of fluid, maintaining the desired flow direction in the pipeline.

3. Minimizing Pressure Drop: The streamlined design of dual plate check valves helps to minimize pressure drop across the valve, ensuring efficient flow performance and operational reliability.

4. Quick Response: Dual plate check valves are known for their fast response time in closing when there is a change in flow direction, reducing the risk of water hammer and pipe damage.

5. Automatic Operation: The operation of dual plate check valves is automatic and does not require external power or control. The mechanism responds to changes in fluid flow direction and pressure independently.

6. Compact Design: Dual plate check valves have a compact design, making them suitable for applications where space is limited or where a lightweight valve solution is preferred.

7. Reliable Seal: The dual plates in the valve provide an effective seal against backflow, minimizing leakage and ensuring system integrity.

8. Low Maintenance: Due to their simple construction and fewer moving parts, dual plate check valves are generally low maintenance components, offering long-term reliability and cost-effectiveness.