- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V 380V 400V 380V/50Hz/three-phase or customized, 380V

-

Power:

-

5.5 X 2

-

Dimension(L*W*H):

-

Customizable

-

Weight (KG):

-

2000

-

Evaporation Capacity(kg/h):

-

1000

-

Product name:

-

Rotary Drying Machine

-

Name:

-

Industrial Dryer Machine

-

Keywords:

-

Fruit Vegetable Mesh Belt Dryer

-

Function:

-

Food Vegetable Fruit Dehydrator

-

After-sales Service Provided:

-

Engineers

-

Usage:

-

Industrial Usage

-

Heating source:

-

Electricity

-

Raw material:

-

Multiple Material

-

Feature:

-

Saving Energy

Quick Details

-

Type:

-

Rotary Drying Equipment

-

Place of Origin:

-

Henan China

-

Brand Name:

-

Santai Machinery

-

Voltage:

-

220V 380V 400V 380V/50Hz/three-phase or customized, 380V

-

Power:

-

5.5 X 2

-

Dimension(L*W*H):

-

Customizable

-

Weight (KG):

-

2000

-

Evaporation Capacity(kg/h):

-

1000

-

Product name:

-

Rotary Drying Machine

-

Name:

-

Industrial Dryer Machine

-

Keywords:

-

Fruit Vegetable Mesh Belt Dryer

-

Function:

-

Food Vegetable Fruit Dehydrator

-

After-sales Service Provided:

-

Engineers

-

Usage:

-

Industrial Usage

-

Heating source:

-

Electricity

-

Raw material:

-

Multiple Material

-

Feature:

-

Saving Energy

Products Description

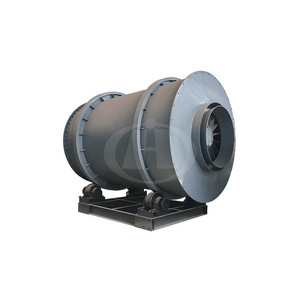

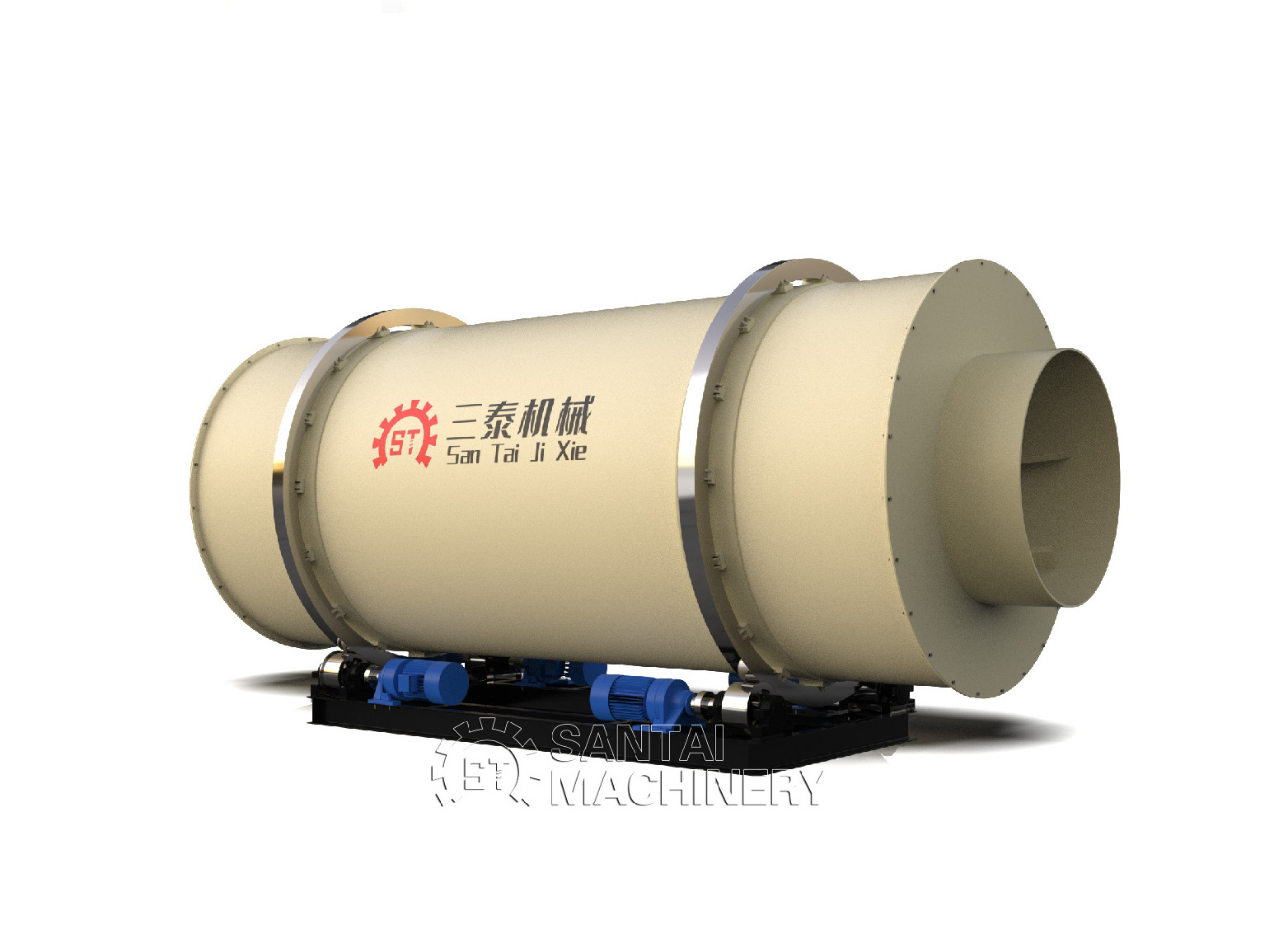

Sludge coal sludge sand high efficiency energy saving three cylinder rotary dryer

The three tube dryer has a high output of materials and minimal fuel consumption. It has the ability to withstand loads, runs smoothly, and has high reliability. When materials enter the machine, they can be dried quickly. Moreover, the three tube dryer has low wear and tear, small maintenance, and reliable operation. It is made of high-quality manganese plate and stainless steel materials, which have a beautiful and generous appearance and are not easy to rust. Its service life is long.

1.The material first goes into the inside drum, because there are the spiral shape boards fixed in the drum, when the dryer make rotary working, the spiral shape board will stir the material and make the material do movement.

2.When the material reaches the right side of the drum, it will go into the second drum for further drying.

3.The same working principle, the material then goes into outside drum, during the drying working process, the material will make three times drying, so the material can be dried completely in this process.

2.When the material reaches the right side of the drum, it will go into the second drum for further drying.

3.The same working principle, the material then goes into outside drum, during the drying working process, the material will make three times drying, so the material can be dried completely in this process.

The three tube dryer is widely used for material drying in industries such as cement, mining, construction, chemical, food, and compound fertilizers. Thermocouples are installed in the feeding and discharging devices to control temperature. The temperature change of the dryer can also be indicated by a thermometer, which facilitates temperature control inside the dryer (usually 250-350 ℃).

|

Model

|

Drun speed

(r/min)

|

Feed water

(%)

|

The moisture content

(%)

|

Capacity

(t/h) |

Power

(kw)

|

Weight

(t)

|

|

1500 x 3000

|

2-7.5

|

10-25

|

≤1

|

5-8

|

2.2 x 2

|

8

|

|

1800 x 4000

|

2-7.5

|

10-25

|

≤1

|

10-15

|

3 x 2

|

13

|

|

2000 x 4500

|

2-7.5

|

10-25

|

≤1

|

15-20

|

4 x 2

|

15.8

|

|

2000 x 6000

|

2-7.5

|

10-25

|

≤1

|

15-22

|

5.5 x 2

|

20

|

Product packaging

All products will be processed to be rustproof and moisture proof before delivery

Using standard export packaging, bare packaging, containers, or according to customer requirements

Using standard export packaging, bare packaging, containers, or according to customer requirements

Hot Searches