Vibration Damping: Rubber vibration isolators effectively dampen vibrations generated by machinery, equipment, or external forces,

reducing noise and preventing damage to sensitive components.

Shock Absorption: They absorb sudden impacts or shocks, protecting equipment and machinery from damage caused by dynamic loads or

external impacts.

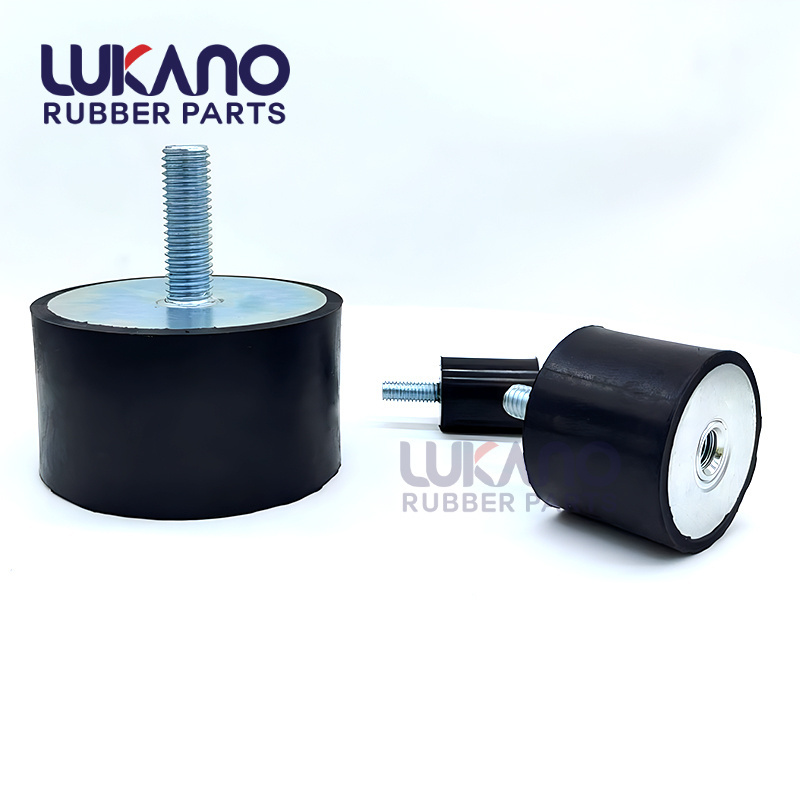

Resilient Rubber Material: Constructed from resilient rubber compounds that deform and compress under load, absorbing energy and

dissipating it as heat.

Flexibility: Rubber vibration isolators provide flexibility, allowing them to adapt to dynamic loads and uneven surfaces without

compromising performance.

Isolation: They isolate machinery and equipment from external vibrations, preventing the transmission of vibrations to surrounding

structures or components.

Stability Enhancement: Rubber vibration isolators help maintain stability and balance in machinery and equipment, improving

overall performance and longevity.

Noise Reduction: By dampening vibrations, rubber vibration isolators help reduce noise levels generated by machinery and equipment

during operation.

Corrosion Resistance: Many rubber vibration isolators feature metal components with corrosion-resistant coatings or materials to

ensure durability and longevity, even in harsh environments.

Customization: Available in various sizes, shapes, and configurations to suit different applications and mounting requirements,

offering versatility and flexibility in design.

Easy Installation: Designed for straightforward installation, rubber vibration isolators can be easily integrated into existing

machinery or equipment setups, minimizing downtime and installation costs.