Options we can include into your tank are:

* Tillable

*

Fully integrated control panel

*

Heated and/or cooled

*

Agitators

*

Loadcells

*

Level switches

*

Cleaning options

*

Skid mounted

- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

10000

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ACE

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

6.5 kW

-

Marketing Type:

-

New Product 2024

-

Tank Volume:

-

50L-30,000L

-

Layer:

-

single/double jacket/three jacket

-

Mixing type:

-

Scraper Mixer Homogenizer Disperser

-

Heating Method:

-

Steam or Electric Heating

-

Keywords:

-

Chemical Processing Equipment Part

-

Tags:

-

stainless steel/high shear/high speed

-

Processing type:

-

Chemicals/Food /liquid/Powder/

-

Additional Functions:

-

Automatic/Multifunction/Vaccum

-

Motor:

-

Domestic/ABB

-

Control:

-

Electronic Control / PLC

Quick Details

-

Barrel Volume (L):

-

600l

-

Max. Loading Volume (L):

-

5000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 2800 r.p.m

-

Max. Loading Capacity:

-

10000

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ACE

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

6.5 kW

-

Marketing Type:

-

New Product 2024

-

Tank Volume:

-

50L-30,000L

-

Layer:

-

single/double jacket/three jacket

-

Mixing type:

-

Scraper Mixer Homogenizer Disperser

-

Heating Method:

-

Steam or Electric Heating

-

Keywords:

-

Chemical Processing Equipment Part

-

Tags:

-

stainless steel/high shear/high speed

-

Processing type:

-

Chemicals/Food /liquid/Powder/

-

Additional Functions:

-

Automatic/Multifunction/Vaccum

-

Motor:

-

Domestic/ABB

-

Control:

-

Electronic Control / PLC

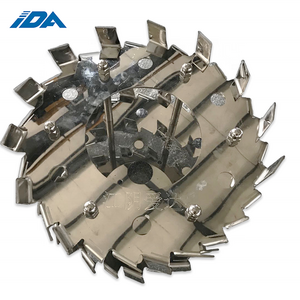

Agitator Tray Stir Dispersion Blade Dispersion Plate Mixer Machine Paddle Stainless Steel Agitator Blade

Custom Made 50L- 30,000L Mixing tank, 22 Years Of Experience. Reasonable Price And Best Service, CE Certificated Products.15-30 day fast delivery. Please contact us for the offer.

Video

Products Description

Mixing tanks come in various sizes and can be used in a wide range of industries.

We are a manufacturer of stainless steel mixing tanks designed to fit your products and processes.

We are a manufacturer of stainless steel mixing tanks designed to fit your products and processes.

Standard mixing tanks or tailor-made for your product and process

Agitator design and fabrication :

In addition to tanks, We also make its own agitators. This way you have one point of contact for the entire tank concept. Agitators that we design and produce are:

*Gate agitator

*Anchor agitator

*Scraping agitator

*

Propeller agitator

*

Bottom driven agitator

*

Dispersing disk

*

Rotor/stator

*

Screw agitator

*

Combination of agitators

*

High shear mixer

*

Turbo mixer

*

Side entry agitator

*

Static mixer

*

External homogenizer

...

We have more than one hundred different types of mixers to meet your product process.

|

Mixing tank

(Accept customized)

|

|

|

|

|||

|

Profile/type

|

Single layer tank

|

Double layer tank

|

Three layer tank

|

|||

|

Material

|

SS304 or SS316L

|

|

|

|||

|

Volume

|

50L-30T (Customized)

|

|

|

|||

|

Tank Type

|

Vertical type/Horizontal type/Mobile type

|

|

|

|||

|

Structure

|

one layer

|

Inner layer+jacket

|

inner layer+jacket+insulation

|

|||

|

heating way

|

Electric/Steam Heating

|

electric/steam heating

|

electric/steam heating

|

|||

|

Inside Finsh

|

Mirror polished Ra<0.4um

|

|

|

|||

|

Outside Finish

|

2B or Satin Finish

|

|

|

|||

|

Stirrer type

|

impeller, Anchor , Turbine , High shear, magnetic mixer, Anchor mixer with scraper

|

low speed

|

High speed

|

|||

|

|

No

|

0-200RPM

|

960-3400RPM

|

|||

|

Power

|

0.55~55KW

|

|

|

|||

|

Voltage

|

110V~480V

|

|

|

|||

|

Top Head type

|

Dish top, Open lid top, Flat top

|

|

|

|||

|

Bottom type

|

Dish bottom, Conical bottom, Flat bottom

|

|

|

|||

|

PARTS DETAILS

|

1.Quick open manhole / Pressure manhole

|

|

|

|||

|

|

2.Various types of CIP cleaners

|

|

|

|||

|

|

3.Sterile respirator

|

|

|

|||

|

|

4.Adjustable Legs

|

|

|

|||

|

|

5.Inlet and Outlet sanitary valve

|

|

|

|||

|

|

6.Thermometer (According to customer requirements )

|

|

|

|||

|

|

7.Paddle blender .(According to customer requirements)

|

|

|

|||

|

|

8.Liquid level meter and lever controller (According to customer requirements)

|

|

|

|||

|

|

9.Ladder

|

|

|

|||

|

Application

|

Food, Beverage, pharmacy, biological,honey, chocolate, alcohol ,chemical industry etc

|

|

|

|||

|

We can customize the mixing equipment according to customer requirements.

|

|

|

|

|||

It has the functions of heating, mixing, scraping, rotating at different speeds and vacuum supply. It has a very wide application

1. Cosmetics: Skin cream, hair gel, lotion, liquid soap, shampoo, etc.

2. Food: Jam, chocolate, sauce, etc.

3. Chemicals: Painting, adhesive, detergent.etc.

1. Cosmetics: Skin cream, hair gel, lotion, liquid soap, shampoo, etc.

2. Food: Jam, chocolate, sauce, etc.

3. Chemicals: Painting, adhesive, detergent.etc.

Details Images

50L Mixing tank Wiht Heating

100L Mixing Tank With Bottom Emulsifier and Lobe Pump

200L single layer mixing tank with wheels

200L three-layer electric heating mixing tank

500L High Shear Mixer Tank With Lobe Pump

300L Mixing tank With Homogenization Pump

500L mixing tank with Explosion-Proof Motor

600L mixing tank with Explosion-Proof

15,000L Mixing tank

20,000L Mixing tank

Packaging & Shipping

We are experienced in the whole packing and shipping process,and we will be responsible for any damage made during shipping and send clients replacements for free.

* Sufficient inner protection with different materials, including bubble bag, foam board and others.

* Qualified wooden package or carton for different products or as customer require

* Strict packing process to ensure the safety and completeness of the goods

FAQ

What Types of Bottoms Do Stainless Steel Mixing Tanks Come In?

There are four basic types of mixing tank bottoms, and each has its advantages and disadvantages.

* Flat Bottom: Flat-bottom tanks have a prevalent and valuable design. Neutral geometry, which works well with solids or liquids,

and a lower manufacturing cost, are benefits of flat bottom mixing tanks. Drainage is the only disadvantage, especially with

solids and significant-viscosity liquids.

* Dished Bottoms: Often used in pressurized tanks, dished bottoms are manufactured in three different geometries: 2:1 Elliptical,

ASME 80:10 and Standard Flange and Dished. Dished bottoms offer increased rigidity, better drainage than Flat Bottoms, and

better solids' suspension than cone designs - except for the 2:1 Elliptical design. But a longer shaft will be needed,

increasing cost, and a special kicker impeller may be needed for the 2:1 Ellipticals.

* Sloped Bottom: Sloped-bottom tanks provide excellent drainage without the need for a longer impeller shaft. However, solids

suspension performance is reduced as the slope increases.

* Cone Bottom: Cone-bottom stainless steel mixing tanks provide superior drainage, critical for high solids content slurries.

Solids suspension, however, should NOT be done in a cone-bottom mixing tank due to fluid stall and stratification potential.

Radial flow and temperature gradients can also be negatively affected. Should I Use a Baffle In My Mixing Tank? Baffles are an excellent addition to use in multiple applications. Ace offers a unique baffle option with various clamp designs. Think of your mixing tank as the bowl used for mixing a cake batter. When using beaters to mix the dry powder, water, oil and eggs, you don't just hold the beater in the middle; you move it around. If it stays in the middle, it won't mix all the ingredients, and your cake will be ruined. Baffles work similarly to ensure the contents being combined move from top to bottom in your mixing tank. Therefore, your material is stirred consistently instead of swirling in place. What are your terms of payment? T/T in advance, 40% as deposit, and finish 70% balance payment before delivery. We'll show you the photos of the products and packages before you pay the balance. What are your terms of delivery? EXW, FOB, CIF, DDU. How about your delivery time? Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. Can you produce according to the samples? Yes, we can produce by your samples or technical drawings. Do you test all your goods before delivery? Yes, we have 100% test before delivery

There are four basic types of mixing tank bottoms, and each has its advantages and disadvantages.

* Flat Bottom: Flat-bottom tanks have a prevalent and valuable design. Neutral geometry, which works well with solids or liquids,

and a lower manufacturing cost, are benefits of flat bottom mixing tanks. Drainage is the only disadvantage, especially with

solids and significant-viscosity liquids.

* Dished Bottoms: Often used in pressurized tanks, dished bottoms are manufactured in three different geometries: 2:1 Elliptical,

ASME 80:10 and Standard Flange and Dished. Dished bottoms offer increased rigidity, better drainage than Flat Bottoms, and

better solids' suspension than cone designs - except for the 2:1 Elliptical design. But a longer shaft will be needed,

increasing cost, and a special kicker impeller may be needed for the 2:1 Ellipticals.

* Sloped Bottom: Sloped-bottom tanks provide excellent drainage without the need for a longer impeller shaft. However, solids

suspension performance is reduced as the slope increases.

* Cone Bottom: Cone-bottom stainless steel mixing tanks provide superior drainage, critical for high solids content slurries.

Solids suspension, however, should NOT be done in a cone-bottom mixing tank due to fluid stall and stratification potential.

Radial flow and temperature gradients can also be negatively affected. Should I Use a Baffle In My Mixing Tank? Baffles are an excellent addition to use in multiple applications. Ace offers a unique baffle option with various clamp designs. Think of your mixing tank as the bowl used for mixing a cake batter. When using beaters to mix the dry powder, water, oil and eggs, you don't just hold the beater in the middle; you move it around. If it stays in the middle, it won't mix all the ingredients, and your cake will be ruined. Baffles work similarly to ensure the contents being combined move from top to bottom in your mixing tank. Therefore, your material is stirred consistently instead of swirling in place. What are your terms of payment? T/T in advance, 40% as deposit, and finish 70% balance payment before delivery. We'll show you the photos of the products and packages before you pay the balance. What are your terms of delivery? EXW, FOB, CIF, DDU. How about your delivery time? Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. Can you produce according to the samples? Yes, we can produce by your samples or technical drawings. Do you test all your goods before delivery? Yes, we have 100% test before delivery

Certifications

Contact Us

Hot Searches