- Product Details

- {{item.text}}

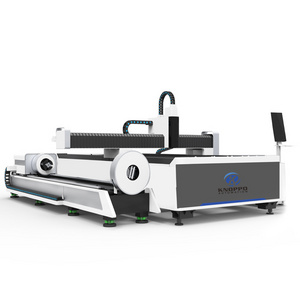

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

Other

-

Cutting Thickness:

-

1-10mm

-

Control Software:

-

Fscut 3000s

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JQ

-

Weight (KG):

-

6000 KG

-

Generator:

-

Raycus/IPG/MAX

-

Rails:

-

Taiwan Hiwin/Itan PEK

-

Gears:

-

Taiwan YYC

-

Cutting head:

-

Precitec/Raytools

-

Control system:

-

Bochu Controller

-

Color:

-

White and black

-

Water chiller:

-

Hanli

-

Weight:

-

8000kg

-

Size:

-

10700*2400*1600

-

Reducer:

-

Japan Shimpo

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

120m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

Other

-

Cutting Thickness:

-

1-10mm

-

Control Software:

-

Fscut 3000s

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JQ

-

Weight (KG):

-

6000 KG

-

Generator:

-

Raycus/IPG/MAX

-

Rails:

-

Taiwan Hiwin/Itan PEK

-

Gears:

-

Taiwan YYC

-

Cutting head:

-

Precitec/Raytools

-

Control system:

-

Bochu Controller

-

Color:

-

White and black

-

Water chiller:

-

Hanli

-

Weight:

-

8000kg

-

Size:

-

10700*2400*1600

-

Reducer:

-

Japan Shimpo

Product Description

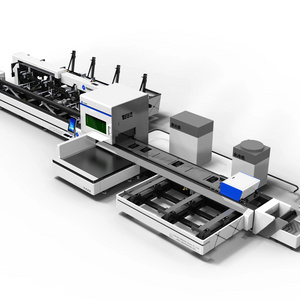

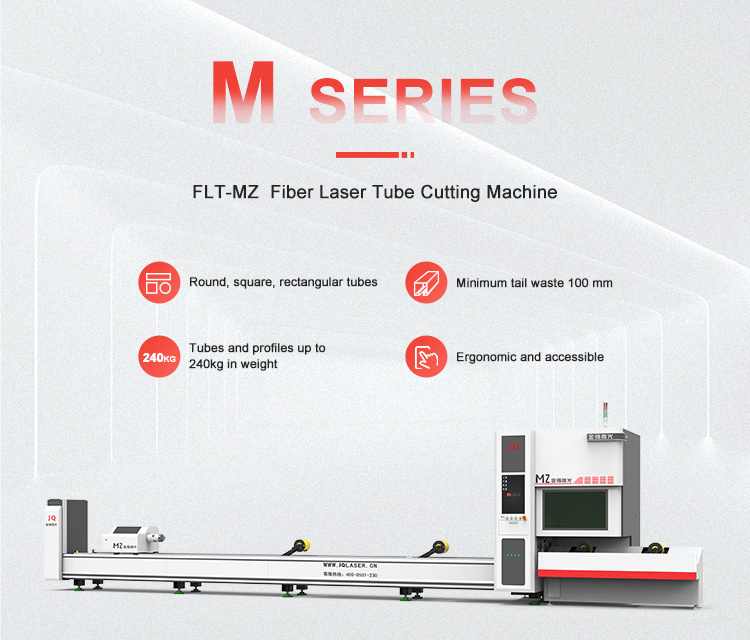

This cutting machine is designed for cutting extremely small diameter pipes on the market. Mainly used for ordinary carbon steel pipes, stainless steel pipes, aluminum alloy pipes, copper pipes, cutting diameter for round pipe Φ15mm-φ120mm, square pipe side length≤80mm, rectangular pipe contour diagonal≤120mm, L≤6250mm.

Product Show

roller support

Fixing the pipe effectively solves the deformation problem in the cutting operation of the long pipe.

rear chucks

1. Max. running speed of rear chuck - 95m/min;

2. Automatic center adjustment for all kinds of tubes;

3. High precision automatic double pneumatic chucks

front chucks

Intelligent clamping, precise perception. It can sensitively capture the state of the chuck clamping and react quickly; real-time wireless data transmission, self-adaptive adjustment of the clamping force.

auto unloading system setails

Unloading device can realize the conveying loading and unloading through the control of the numerical control system, and complete the real-time connection with the pipe cutting machine. The finished product is automatically dropped to the storage bin, double support-bearing auxiliary support overlong tubes.

high power fiber laser

Using well-known fiber laser tools, whcih photoelectric conversion efficiency is high, power consumption is low.

Power Distribution Cabinet

Independent electric control cabinet, making a easier operating and maintaining.

Product Paramenters

|

NO.

|

Item

|

Parameter

|

Unit

|

|

1

|

Maximum cut pipe length

|

0~6400 (more than 3 meters need to extend the front joint material)

|

mm

|

|

2

|

Cut pipe diameter

|

16~220 (external circle of workpiece)

|

mm

|

|

3

|

Minimum tail material

|

90

|

mm

|

|

4

|

X,Y positioning accuracy

|

±0.05/1000mm

|

mm

|

|

5

|

X,Y repeat positioning accuracy

|

±0.03/1000mm

|

mm

|

|

6

|

Acceleration speed

|

1.5G

|

m/s²

|

|

7

|

Max running speed

|

100

|

m/min

|

|

8

|

Max. speed of chuck

|

150

|

rpm

|

|

9

|

Chuck load weight

|

Front and rear chucks 120Kg each

|

mm

|

|

10

|

Weight of loading machine

|

5000

|

Kg

|

|

11

|

Main machine shape (length, width and height)

|

Approx. 10700×3700×2410

|

mm

|

|

12

|

Laser power

|

1

|

kw

|

|

13

|

Control system

|

Bertrud 5000B

|

|

|

14

|

Power of the whole machine

|

24

|

kw

|

|

15

|

Power supply requirements

|

380v/50Hz

|

|

Sample

Hot Searches