1. LPG/ gas burner kindle the machine. The machine needs to be preheated, which takes about 1 hour. It takes 20-30kg of LPG to kindle once, and the whole process only needs to kindle the LPG once.

2. When the preheating temperature reaches 280°-330°, the preheating is completed, and the raw materials are put in (when the raw material is coconut husk, the furnace temperature is 330 degrees, and the raw materials are lighter raw materials such as palm husk, rice husk, and wood chips. Discharge when the temperature in the furnace reaches 280°.)

3. Kindle the combustion chamber. After carbonization for 10-20 minutes, feel and observe that there is hot gas generated in the combustion pool, light the gas, the combustion chamber burns, close the flame, and no longer use LPG.

4. A round of carbonization takes 20 minutes

5. The discharging is a cooling process, the condenser tube, double layer, the carbonized raw material is discharged inside, and the outside is filled with water for cooling.

- Product Details

- {{item.text}}

Quick Details

-

Effective Volume:

-

19 cubic meters

-

Dimension(L*W*H):

-

12*5*6m

-

Voltage:

-

380V

-

Power:

-

38kw

-

Weight (KG):

-

22000

-

Product name:

-

Continuous rotary drum carbonization furnace

-

Applicable raw materials:

-

Coconut shell, wood chips, sawdust, palm kernal, rice husk

-

Type:

-

Rotary Continuous Carbonization

-

Capacity:

-

800-1000kg/h

-

Carbonization time:

-

15-20 minutes

-

Heating source:

-

LPG/Natural Gas+ Syngas

-

Carbonization method:

-

Destructive Distillation

-

Temperature:

-

700-800 centigrade

-

Carbonizing rate:

-

99%

-

Operation:

-

Automatic control

Quick Details

-

Place of Origin:

-

HEN

-

Marketing Type:

-

Large Capacity Carbonization Equipment

-

Brand Name:

-

Fonoda Machinery

-

Effective Volume:

-

19 cubic meters

-

Dimension(L*W*H):

-

12*5*6m

-

Voltage:

-

380V

-

Power:

-

38kw

-

Weight (KG):

-

22000

-

Product name:

-

Continuous rotary drum carbonization furnace

-

Applicable raw materials:

-

Coconut shell, wood chips, sawdust, palm kernal, rice husk

-

Type:

-

Rotary Continuous Carbonization

-

Capacity:

-

800-1000kg/h

-

Carbonization time:

-

15-20 minutes

-

Heating source:

-

LPG/Natural Gas+ Syngas

-

Carbonization method:

-

Destructive Distillation

-

Temperature:

-

700-800 centigrade

-

Carbonizing rate:

-

99%

-

Operation:

-

Automatic control

Product Description

24 hours Continuous Working Rotary Drum Carbonization Furnace

This carbonization furnace is a continuous ratory drum type carbonization furnace. It can carbonize different materials into charcoal, such as sawdust, wood chips, rice husk, olive waste, coconut shells, nuts shell,sugarcane bagasse,small things etc. Finished charcoal can be sold in the market directly, or deep processing into BBQ charcoal, shisha charcoal, etc.

Rotary carbonization furnace is high-automatic carbon-making equipment. Its carbonization raw materials are very diverse and most of them are agricultural and forestry wastes, fruit husks, and industrial scraps. Peanut husk charcoal, rice husk charcoal, bamboo shaving charcoal, coconut husk charcoal, apricot husk charcoal, coffee ground charcoal, etc. They are produced through the carbonization mechanism. The carbon material produced by the continuous carbonization furnace is clean, non-toxic, smokeless, and has good plasticity. In short, the market prospect of the rotary carbonization furnace is broad.

Rotary carbonization furnace is high-automatic carbon-making equipment. Its carbonization raw materials are very diverse and most of them are agricultural and forestry wastes, fruit husks, and industrial scraps. Peanut husk charcoal, rice husk charcoal, bamboo shaving charcoal, coconut husk charcoal, apricot husk charcoal, coffee ground charcoal, etc. They are produced through the carbonization mechanism. The carbon material produced by the continuous carbonization furnace is clean, non-toxic, smokeless, and has good plasticity. In short, the market prospect of the rotary carbonization furnace is broad.

Fonoda machinery is a professional charcoal machine manufacturer for over 10 years and we are constantly upgrading how to produce high- quality charcoal carbonziation machines with high efficiency and large output and provide the customers professional biochar| charcoal production line.

Specification

|

No

|

Model

|

Drum Size

|

Capacity( output)

|

Whole unit includes

|

|

1

|

FND-R1000

|

φ1 * 11m

|

300-500KG/H

|

Feeding conveyor,

Furnace+ Preheating LPG System,

Flammable gas recycle re-use system,

Purification system,

Discharge cooling conveyor,

Explosion- proof design.

|

|

2

|

FND-R1200

|

φ1.2 * 11m

|

500-600KG/H

|

|

|

3

|

FND-R1500

|

φ1.5 * 11m

|

600-800KG/H

|

|

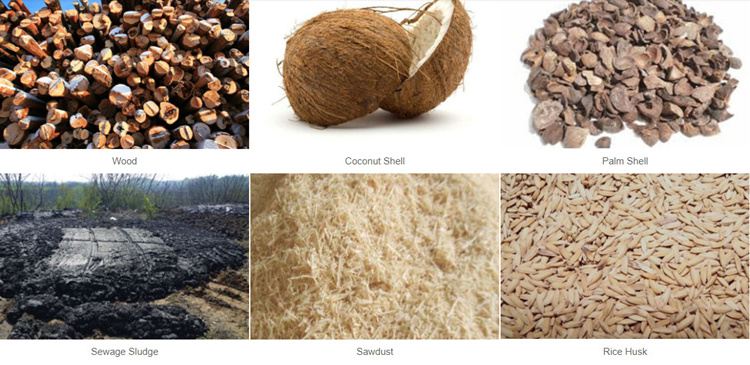

Raw Materials for Rotary Carbonization Furnace

It's designed for smaller sized materials, the sawdust carbonization furnace can carbonize raw materials such as sawdust, rice husks, peanut husks, plant straws, coconut shell, sunflower husks, apricot husks, distiller’s grains, coffee grounds, etc. The raw material of the biomass carbonization furnace is characterized by small materials. They are powder and particles.

Because it's continusouly feeding, carbonizing and discharging, normally materials will stay in the furnace for only 15-20 minutes to be fully carbonized, and we will need use recycled gas from materials carbonization itself. So we suggest using thickness below 3mm, size below 50mm.

Main Features of Continuous Rotary Sawdust Charcoal Carbonization Furnace/Pinenut shell charcoal production kiln

1) High ouput and Strong continuity.

2) Fully automatic and confined environment.3) Combustible gas can be recycled ,reduce the cost .

4) Simple structure in linear type ,easy in installation and maintation.

5) High pressure double crank to control the die opening and closing.

6) Energy saving and envirenmentally freindly, turn waste into treasure.

7) Running in a high automatization and intellectualization,no pollution.

8) With dust removal system ,The equipment can achieve EU environmental protection standards.

9) Main Attached Stainless Steel 310S material(IF YOU ASK), high temperature resistance,and the life span up to 5-8 years.

10)Automatic collection of tar and recycling of combustible gases to protect the environment and rational recycling of resources.

2) Fully automatic and confined environment.3) Combustible gas can be recycled ,reduce the cost .

4) Simple structure in linear type ,easy in installation and maintation.

5) High pressure double crank to control the die opening and closing.

6) Energy saving and envirenmentally freindly, turn waste into treasure.

7) Running in a high automatization and intellectualization,no pollution.

8) With dust removal system ,The equipment can achieve EU environmental protection standards.

9) Main Attached Stainless Steel 310S material(IF YOU ASK), high temperature resistance,and the life span up to 5-8 years.

10)Automatic collection of tar and recycling of combustible gases to protect the environment and rational recycling of resources.

Other equipment you will need:

If your raw materials are some large wood chips, branches, shavings, etc., they cannot meet the requirements of the drum charring furnace. Don’t worry, you only need to equip a hammer mill in front of the feed system to get the raw materials that meet the production requirements. In addition, the humidity of wood chips should be below 20%. So you can choose to dry naturally or choose a sawdust dryer to reduce the humidity of the raw material.

Muilti- function Chopper

Also called comprehensive crusher, able to process large amount mass of raw materials with high capacity, easy loading, and strong processing capacity.

Rotary drum dryer for biomass

Continuous rotary drum drying equipment for different capacity factory, all can be customzied according to the production line moisture humidity condition.

The advantage of the continuous carbonization furnace

The continuous charcoal making machine, machine also named continuous pyrolysis furnace is a new type of machine that feeds raw materials and outputs finished materials at the same time. It belongs to an external heating drying and carbonization integrated machine.The flue gas generated in the entire production process is self-utilized, and the exhaust gas passes through the flue gas treatment device.Processing, does not pollute the environment, after technical improvement, the furnace can also be used to recycle and process electronic waste, and realize the recycling of metals and pyrolysis the plastic into carbon, realizing the sorting of metal and plastic.

Working Process

Packing & Delivery

Use wooden case or whole container based on the model size.

Ship by sea to your seaport.

Hot Searches