Technical Advantages of KGPS MF Melting FurnaceEquipment cost is low. Equipment structure is relatively simple, cost is low.Mature

technology. After more than ten years continuously improve,the technical of KGPS has already very mature.Well-adapted. Low

requirement to environment and durable.Simple Maintenance. Because of it’s simple circuit and the low cost component, so the

maintenance is simple and cost is low.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380

-

Dimension(L*W*H):

-

890*920*900mm or as your request

-

Weight (T):

-

1 T

-

Power (kW):

-

800

-

Application:

-

Precious Metal Melting Machines

-

Melting Material:

-

Aluminium Scrap

-

Product Name:

-

Induction Metal Melting Furnace

-

Capacity:

-

10kg~50ton

-

Material:

-

Metal Material, aluminum shell

-

After-sales Service Provided:

-

Online Support

-

Certification:

-

ISO9001, CE

-

Melting Capacity:

-

0.15Ton-50Ton

-

Function:

-

Metal smelting, steel shell Induction Furnace

Quick Details

-

Place of Origin:

-

Shandong,China

-

Marketing Type:

-

New Product

-

Brand Name:

-

SHUNCHENG

-

Voltage:

-

380

-

Dimension(L*W*H):

-

890*920*900mm or as your request

-

Weight (T):

-

1 T

-

Power (kW):

-

800

-

Application:

-

Precious Metal Melting Machines

-

Melting Material:

-

Aluminium Scrap

-

Product Name:

-

Induction Metal Melting Furnace

-

Capacity:

-

10kg~50ton

-

Material:

-

Metal Material, aluminum shell

-

After-sales Service Provided:

-

Online Support

-

Certification:

-

ISO9001, CE

-

Melting Capacity:

-

0.15Ton-50Ton

-

Function:

-

Metal smelting, steel shell Induction Furnace

Products Description

SHUNCHENG--Electric induction metal melting aluminum shell industrial furnace manufacturer

Intermediate frequency smelter induction:

The medium frequency smelting furnace mainly used for melting and refining all kinds of scrap metal, iron, stainless steel, copper, aluminum. This furnace can smelting the scrap iron, like scrap auto parts, scrap steel bars,scrap screws, iron leftover materials etc.

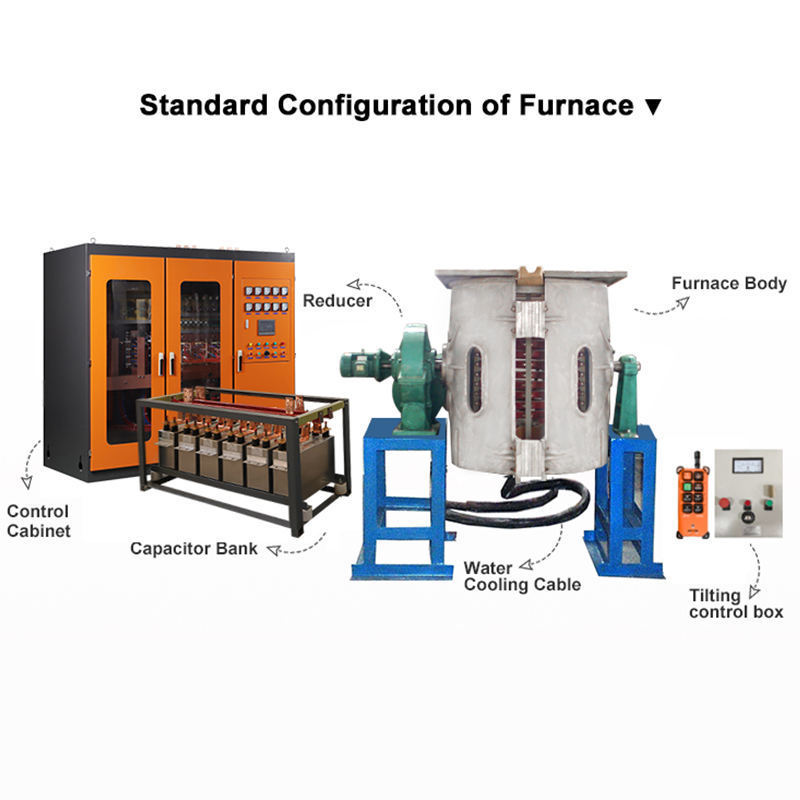

Aluminum Shell Melting Furnace(Reducer Tilting)

Power supply:

Medium Frequency Power Supply improves circuit technology, develops and becomes newest medium frequency power supply in China, with configuration of 8th digitization circuit board. This power supply has wide frequency

scope, constant capacity control, scan automatically zero-pressure start, double voltage and currency closed loop feedback system.And with rigorous protections of overcurrency, overvoltage, undercurrency, undervoltage, lack of water, defaut phase, gives equipment high stability and self automatically control and adjustment.

Product Features:

1. Various capacity 0.1T -20T, fast melting speed, 40-60 minutes /pot.

2. Have self-test function, real-time supervise.

3.

Have leaking alarm device, PLC control, easy to operate.

4.

The control cabinet is standard of the automobile line, easy to maintain.

5.

The water way uses carbon-free hose , water separetors and clips use 304 stainless steel.

6.

Can meet 24 hours continuous work.

7.

High efficiency , low cost , easy to maintain, energy saving ,safe and stability.

Enclosed type Water Cooling System

The materials of coil group is high quality of T2 depickling copper tube or stainless steel pipe .Set water tank

and the tower body is made of aluminum zinc steel plate plate and the service life is over 15years.

and the tower body is made of aluminum zinc steel plate plate and the service life is over 15years.

Spay system with collection device, absorb water, collect mist, lower consumption. With professional full closed low speed low-power motor, low noise, low power consumption. Use distilled water circulating cooling, isolating from the air, water does not scale. Low operating costs, low maintenance costs. No need of water pool, occupies small area, and moves easily.

Product Paramenters

Details Images

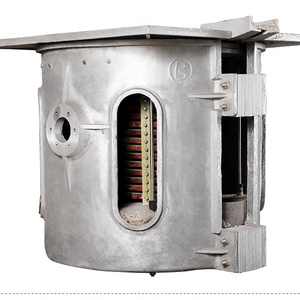

Furnace Parts:

1.Furnace Parts:

The mechanical parts of the MF furnace consisted of furnace pot,water power introduced into the system, titling device and other parts.

2.Furnace Ports:

Furnace port including furnace shell, induction coil etc.

3.Furnace Shell

Furnace shell made of cast aluminum furnace shell halves connected together, with good rigidity, compact structure, easy maintenance, etc., the rotary bearing hole once processed, to ensure concentricity of the furnace shell and rotary bearing tilting furnace process will not be deformed due to misalignment.

The melting furnace mainly composed of power control cabinet and melting furnace body.

* The equipment can meet 24 hours of continuous work.

* It have self-test function and leaking alarm device.

Real-time detection of water temperature, water pressure, over-current, over-voltage, lack phase information

* The equipment can meet 24 hours of continuous work.

* It have self-test function and leaking alarm device.

Real-time detection of water temperature, water pressure, over-current, over-voltage, lack phase information

Tilting Reducer:

The tilting reducer is equipped with three-stage turbine speed. With good self-locking and stable rotary performance.

Capacitor Bank :

The double-layer mica insulation technology is used for the insulation treatment of the capacitor.

Even if water is sprayed on the capacitor accidentally, the insulation strength of the cabinet can be ensured.

Even if water is sprayed on the capacitor accidentally, the insulation strength of the cabinet can be ensured.

Induction Melting Furnace:

It has the bottom of the oxygen blowing, reducing carbon, slagging function.

Cyclone type smoke hood has excellent dust absorption , thermal insulation effect and take up a small space.

Long service life.

Cyclone type smoke hood has excellent dust absorption , thermal insulation effect and take up a small space.

Long service life.

Power Supply:

The utility model has the advantages of obvious energy saving effect and 20% saving compared with common equipment.It can achieve that one power supply cabinet for two furnaces.Transformer utilization rate is high.

Closed type cooling tower:

Heat exchanger:The materials of coil group is high quality of T2 depickling copper tube or stainless steel pipe .Set water tank and the tower body is made of aluminum zinc steel plate plate and the service life is over 15years.

Hot Searches