- Product Details

- {{item.text}}

Quick Details

-

power:

-

1.5kw

-

Number of knives:

-

12

-

Hole location:

-

9

-

weight:

-

84kg

-

Wire stripping range:

-

1-42mm

-

size:

-

580*410*500mm

Quick Details

-

Place of Origin:

-

China

-

Weight (KG):

-

38

-

Marketing Type:

-

Hot Product 2022

-

power:

-

1.5kw

-

Number of knives:

-

12

-

Hole location:

-

9

-

weight:

-

84kg

-

Wire stripping range:

-

1-42mm

-

size:

-

580*410*500mm

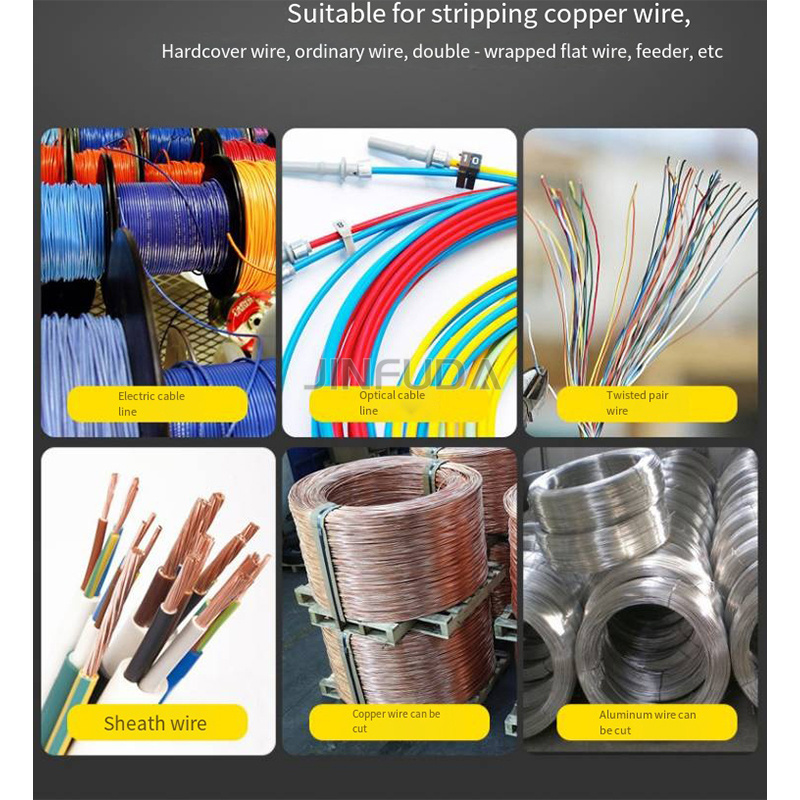

This machine is easy to operate, easy to carry, can be processed single core copper wire, double core copper wire.

1. Compare the wire diameter with the wire feeding hole on the machine, and feed one wire at a time. Before wire feeding, please cut off the wire tip to avoid blade clearance.

2. On the output side, if the cut of the wire is too deep, check the following: Adjust the handle on the input side and tighten

or loosen the handle. (M12 handle) Check that the wire is in the correct position when feeding. Make sure the blade is sharp, if not, sand it with a whetstone.

3. On the output side, if you see that the plastic (PVC) has been peeled, but the copper wire cannot be discharged, please check the following points: Polish the upper shaft with a whetstone. Check if the spring is loose. If so, tighten it. The diameter of the wire is too small, please adjust the spacing between the two axes to 0.3-0.6mm. If the wire to be stripped is hot, do not strip the copper wire.

4. If the wire is stuck in the shaft, check the following points: If the spring on the press wheel is too tight, release it.

There is too much oil on the cable, please wipe it.

5. If blade tilt is seen: Check whether the center regulator is loose. Centering adjustment, adjust the screws on both sides.

2. On the output side, if the cut of the wire is too deep, check the following: Adjust the handle on the input side and tighten

or loosen the handle. (M12 handle) Check that the wire is in the correct position when feeding. Make sure the blade is sharp, if not, sand it with a whetstone.

3. On the output side, if you see that the plastic (PVC) has been peeled, but the copper wire cannot be discharged, please check the following points: Polish the upper shaft with a whetstone. Check if the spring is loose. If so, tighten it. The diameter of the wire is too small, please adjust the spacing between the two axes to 0.3-0.6mm. If the wire to be stripped is hot, do not strip the copper wire.

4. If the wire is stuck in the shaft, check the following points: If the spring on the press wheel is too tight, release it.

There is too much oil on the cable, please wipe it.

5. If blade tilt is seen: Check whether the center regulator is loose. Centering adjustment, adjust the screws on both sides.

|

Model

|

JFD-38

|

JFD-009

|

|

Voltage

|

110V/220V

|

110V/220v

|

|

Power

|

0.75KW

|

1.5kw

|

|

Number of knives

|

10

|

12

|

|

Hole location

|

11

|

9

|

|

Wire stripping range

|

1.5-38mm

|

1.5-42mm

|

|

Weight

|

38kg

|

84kg

|

|

Size

|

580*280*370mm

|

580*410*500mm

|

Hot Searches