- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

10000 KG

-

Power:

-

Customizd

-

Dimension(L*W*H):

-

customization

-

Name:

-

Steel Sheet Plate Shot Blasting Machine Painting Line

-

Application:

-

Cleaning profile steel

-

Type:

-

roller conveyor type

-

Function:

-

clean structural steel

-

Cleaning material:

-

steel shot

-

Abrator:

-

customized

-

Color:

-

customized

-

Advantage:

-

long lifetime

-

Dust collector:

-

bag or filter cartridge type

-

Certification:

-

ce,ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ATHI

-

Marketing Type:

-

Hot Product 2021

-

Weight (KG):

-

10000 KG

-

Power:

-

Customizd

-

Dimension(L*W*H):

-

customization

-

Name:

-

Steel Sheet Plate Shot Blasting Machine Painting Line

-

Application:

-

Cleaning profile steel

-

Type:

-

roller conveyor type

-

Function:

-

clean structural steel

-

Cleaning material:

-

steel shot

-

Abrator:

-

customized

-

Color:

-

customized

-

Advantage:

-

long lifetime

-

Dust collector:

-

bag or filter cartridge type

-

Certification:

-

ce,ISO

Product Overview

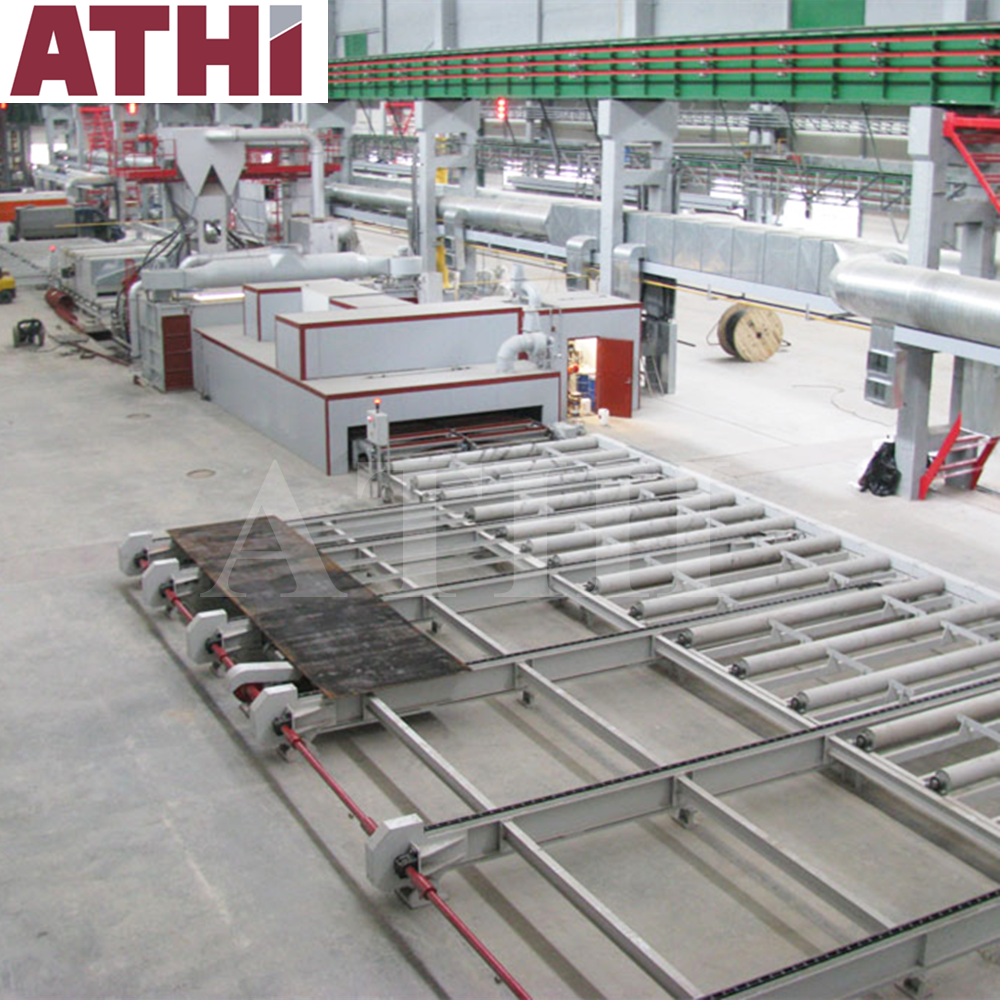

Pass Through Type Roller Conveyor Abrasive Shot Blasting Machine/Steel Plate Surface Cleaning Blaster

Steel structure shot blasting machine is mainly used for steel plate and profile surface cleaning, welding stress removing and coating adhesion ability improving. The machine has been widely used in shipbuilding, locomotive, bridge building, machinery and steel structure fabrication industry. Specially designed for blasting steel plate, sectional steel, beams or structure. Shot blasting machine for steel plate, section steel, beams, bars is designed and produced by adopting the advantages of similar products from both within the country and abroad. The rusting cleaning part (shotblast cleaning) adopts high-efficient blast wheel and full shutter type shot sand separator. The sweeping machine adopts specially made high-strength nylon rolling brush and high-pressure ventilator. The preheating and drying part may adopt various heating methods. The paint spraying part adopts high-pressure airless spraying method. The complete set of equipment is controlled by PLC, and is the large-size complete equipment of international advanced. It is mainly used for surface treatment (namely preheating, rust removal, paint spraying and drying) of steel plate and various structural sections, as well as for cleaning and strengthening of metal structural parts.

Feature:

1.This Steel structure shot blasting machine use high speed cantilever centrifugal type turbine blast wheels. Curve blades blast wheel has more blasting force to process steel products.

2.Material of blades, abrasive distributor, and control cage is high chrome, which can be used over 500 hours. Another option is Taiwan made special material blades, which has 1000-1500 hours lifetime.

3.Blasting cabinet liner material is casted Manganese steel 13, which has good hardness and impact force absorbing ability, which makes its life longer than one year. Another option is rolled Manganese steel, which has life more than two years.

4.Roller conveyor is controlled by frequency converter, which can adjust moving speed to fit for different blasting purpose.

5.Full shutter type air wash separator has three steps separating, which effectively separate dust and abrasive. It is good for abrasive recycle, improve cleaning effect and protect the machine.

4.Roller conveyor is controlled by frequency converter, which can adjust moving speed to fit for different blasting purpose.

5.Full shutter type air wash separator has three steps separating, which effectively separate dust and abrasive. It is good for abrasive recycle, improve cleaning effect and protect the machine.

6.Blowing nozzles are used at end of chamber to blow off the remaining steel ball and dust.

7.Pulse jet bag type dust collector, dust remove efficiency is over 99%. Good for environmental protection. Cartridge type dust collector is optional.

8.Safety protection, electrical interlock, failure self detection and alarming function. Full range of automatic control.

9.ABB motor, SEW gear box, SKF/NSK bearings, SIEMENS/Mitsubishi PLC,Mitsubishi/SIEMENS touch screen, Schneider electric components are optional selection.

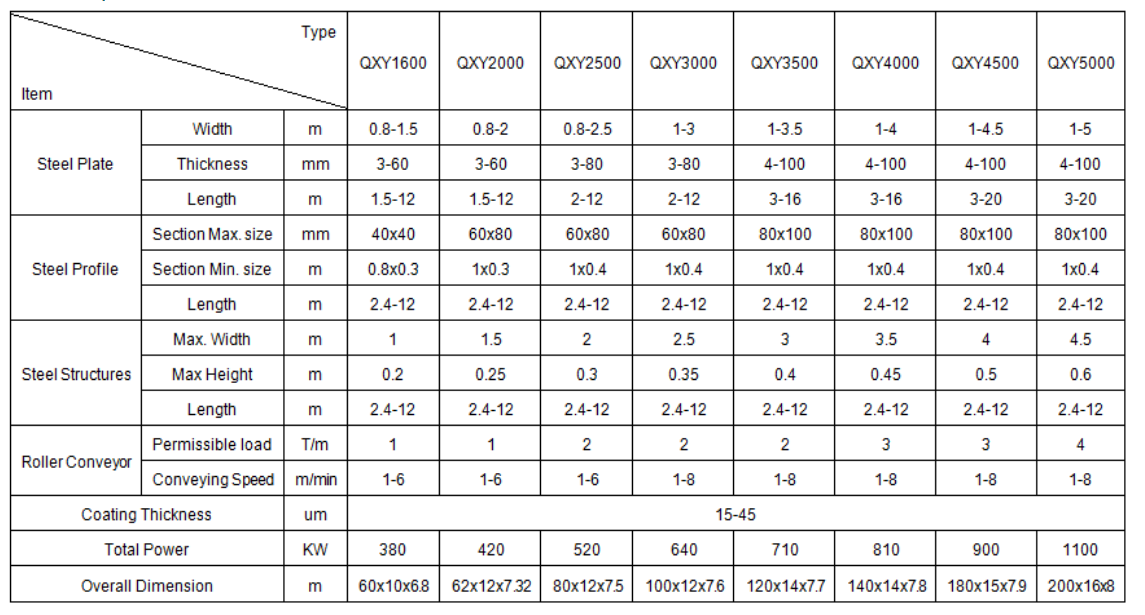

PRODUCT SPECIFICATIONS

Details Images

Hot Searches