High density of silk bridge, strong final adhesion, firmly adhesion objects

2. Non-toxic formula

Select high quality raw materials, adopt toluene free formula, harmless to human body

3. Durable

Faster drying than ordinary glue, can improve the efficiency of brushing

4. ISO standards

International ISO quality system certification, product quality is more guaranteed

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

KAILUN#8566

-

Advantage:

-

Anti Slid

-

Application:

-

Sports Courts

-

Material:

-

MDI,polyether

-

Density:

-

1.0~1.11g/cm3

-

NCO:

-

6.5~7.5%

-

Viscosity:

-

3500~4400Mpas

-

Package:

-

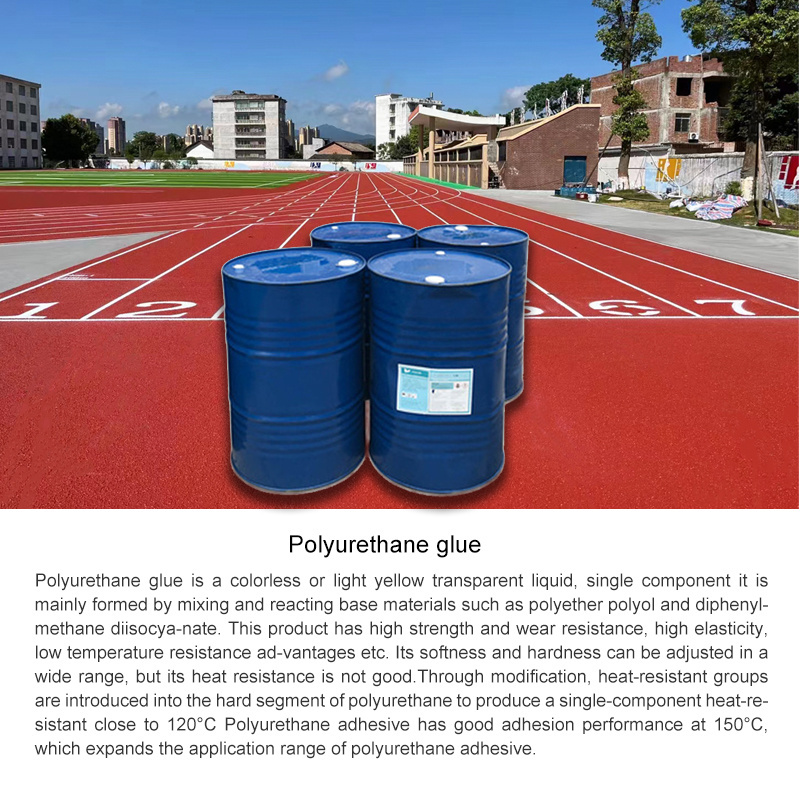

210 L iron drum 200 kg/drum

-

Product Name:

-

PU adhesive for Plastic Sports Track

-

Storage period:

-

Nine months

-

CAS No.:

-

7085-85-0

Quick Details

-

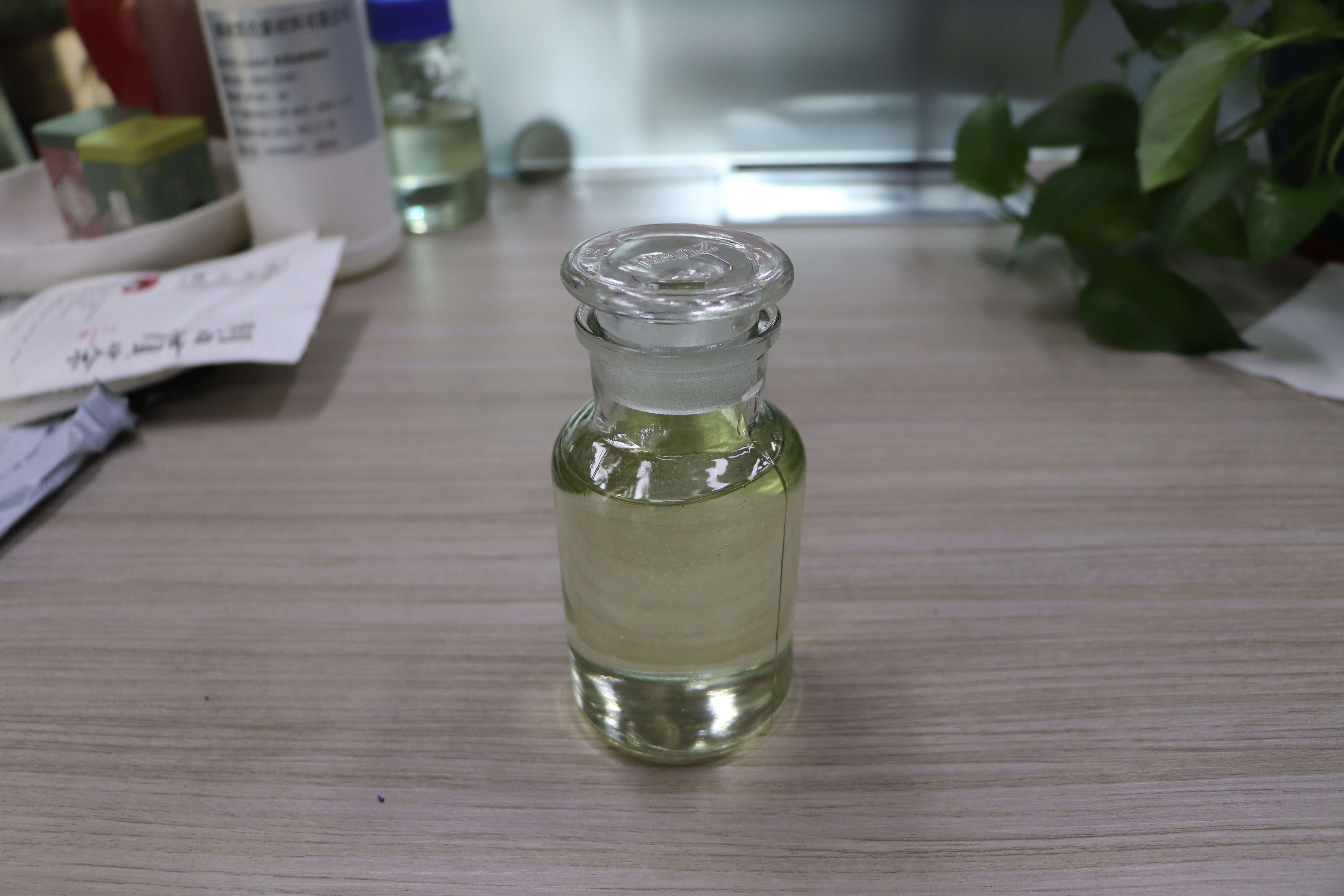

Color:

-

Pale yellow

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KAILUN

-

Model Number:

-

KAILUN#8566

-

Advantage:

-

Anti Slid

-

Application:

-

Sports Courts

-

Material:

-

MDI,polyether

-

Density:

-

1.0~1.11g/cm3

-

NCO:

-

6.5~7.5%

-

Viscosity:

-

3500~4400Mpas

-

Package:

-

210 L iron drum 200 kg/drum

-

Product Name:

-

PU adhesive for Plastic Sports Track

-

Storage period:

-

Nine months

-

CAS No.:

-

7085-85-0

Product Description

|

item

|

Value

|

|

Advantage

|

Anti Slid

|

|

Application

|

Sports Courts

|

|

Material

|

MDI,polyether

|

|

Density

|

1.0~1.11g/cm3

|

|

NCO

|

6.5~7.5%

|

|

Viscosity

|

3500~4400Mpas

|

|

Package

|

210 L iron drum 200 kg/drum

|

|

Product Name

|

PU adhesive for Plastic Sports Track

|

|

CAS No.

|

7085-85-0

|

KAILUN#8566 is pale yellow liquid at room temperature. Mainly used for one - component or two - component polyurethane coatings and adhesives.

Why Choose Us

1. Strong adhesion

Glue Test Report

Product Details

Adhesive Material description

Precautions for storage (use)

KAILUN#8566 is a reactive chemical that can easily react with water to produce insoluble urea compounds and emit carbon dioxide, causing drums and increasing viscosity. So in the process of storage, it is necessary to ensure that the container is strictly dry and sealed and protected by nitrogen.

KAILUN#8566 should be placed at room temperature (15 ~ 25℃) in a well-ventilated room, strictly sealed storage, if the storage temperature is too low (below 0℃) can lead to crystallization, so be sure to pay attention to anti-freezing. Once the crystallization occurs, the crystallization must be heated and melted in the shortest time. It is recommended to use a hot air oven equipped with drum rolling device for drying at 70-80℃. Local overheating is strictly prohibited, as the product will decompose and produce gas in excess of 230℃. It is recommended to use a hot air oven equipped with drum rolling device for drying. After drying, the materials must be mixed evenly in the bucket.

KAILUN#8566 should be avoided at above 50℃ for a long time to avoid the formation of insoluble solids and increase in viscosity. Under suitable storage conditions, the storage period is 9 months. If the physical and chemical properties of the products beyond the shelf life are within the index range, generally their performance will not be affected.

KAILUN# 8566 for no solvent MDI adhesive, in line with the GB 36246-2018 "synthetic material surface of primary and secondary schools sports venue" china-africa solid materials environmental protection standards, customers use KAILUN# 8566, should pay attention to choose to meet the requirements of engineering environmental protection standard of rubber particles and other auxiliary materials, adhesive and accessory products offered by my company only for the environmental performance of the related responsibility.

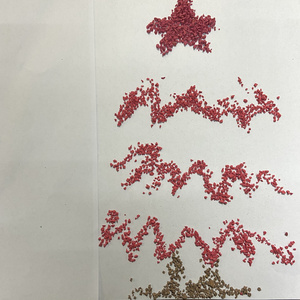

When KAILUN# 8566 used for bonding rubber particles, the construction experience of construction personnel and bonding of rubber particles have higher requirements, the bonding effect in addition to the associated with glue, and colloidal particles category, sizing amount, temperature and humidity conditions of the construction and construction method has the very important relationship, so please read this manual before use products, and do the test in the same conditions, evaluation qualified after the construction.

KAILUN#8566 is a single-component plastic adhesive, and its curing principle is single-component wet curing, namely with the moisture in the air

Reaction curing, so the curing speed and air temperature, humidity has a great correlation. Under the condition of 25℃ and 50% relative humidity, the surface drying time was 8-12h. It was basically guaranteed that the surface layer could be spread after 12h after the bottom colloidal particles were laid. The curing speed of KAILUN#8566 is slower than that of general pure MDI plastic adhesive, which is more suitable for high temperature and humidity in the peak period of plastic construction and provides a longer operation time for large-scale mechanical spreading. If the temperature and humidity are low (the temperature is less than 20℃, the relative humidity is less than 50%, one of the two conditions meets), the catalyst can be appropriately added for use, and the curing speed can be adjusted

Recommended sizing ratio:

|

Types of colloidal particles

|

Colloidal particle: Binder ratio

|

|

2-4mm rubber particles

|

7:1

|

|

1-3mm rubber particles

|

6:1

|

The above recommended proportion is limited to the rubber particles selected in our laboratory. The physical properties of the plastic surface material are closely related to the type of rubber particles and the amount of sizing. The specific construction proportion can be adjusted by ourselves according to the specific conditions before construction and the small test with customers.

Shelf life

The storage period of the product shall be 9 months from the date of production if the product is stored in accordance with the specified storage conditions.

For safety and environmental information, please refer to our product safety data sheet or contact our customer service center.

Application

Hot Searches