- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

400 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Haisi

-

Voltage:

-

380v or customized

-

Dimension(L*W*H):

-

capacity

-

Power (kW):

-

132

-

Weight:

-

4T

-

L/D:

-

32-64

-

speed:

-

600r/min

-

Torque:

-

2560N.m

-

Capacity:

-

400kg/h

-

Motor Brand:

-

Simens or WNM

-

Inverter Brand:

-

ABB

-

Motor pole:

-

four-pole motor

-

Color:

-

as require

-

Power(W):

-

132

-

Certification:

-

CE TUV

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

44

-

Screw diameter (mm):

-

71 mm

-

Screw Speed (rpm):

-

400 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Haisi

-

Voltage:

-

380v or customized

-

Dimension(L*W*H):

-

capacity

-

Power (kW):

-

132

-

Weight:

-

4T

-

L/D:

-

32-64

-

speed:

-

600r/min

-

Torque:

-

2560N.m

-

Capacity:

-

400kg/h

-

Motor Brand:

-

Simens or WNM

-

Inverter Brand:

-

ABB

-

Motor pole:

-

four-pole motor

-

Color:

-

as require

-

Power(W):

-

132

-

Certification:

-

CE TUV

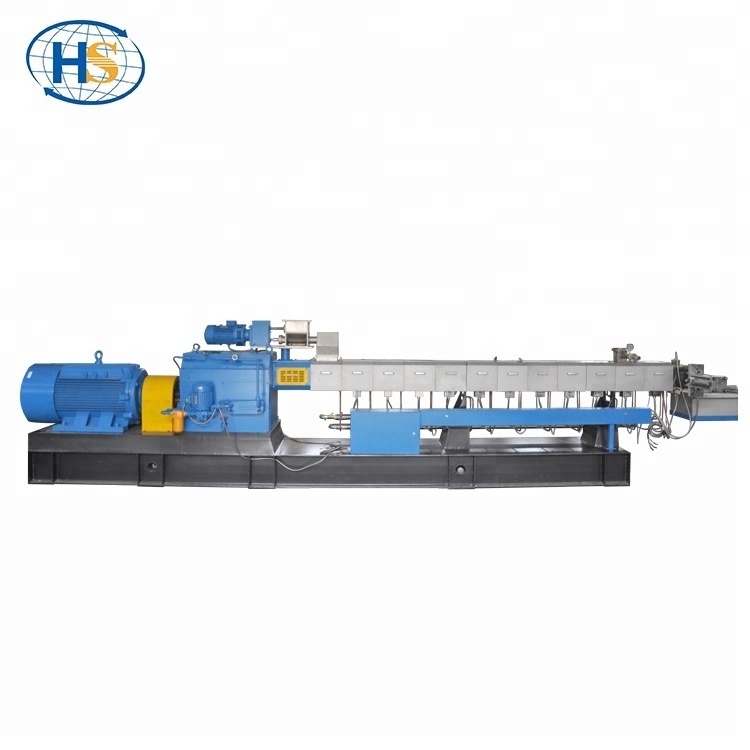

High Quality TPR Pelletizing Extruder

Technical Data:

|

Mode |

Diameter (mm) |

L/D |

speed (r/min) |

Motor power (kw) |

Torque (N.m) |

Capacity (kg/h) |

|

TSE-20 |

22 | 32-44 | 600 | 5.5 | 43 | 0.5-10 |

|

TSE-30B |

31 | 32-48 | 600 | 15 | 119 | 5-40 |

|

TSH-35B |

35.6 | 32-52 | 600-800 | 15-22 | 119 | 30-70 |

|

TSE-40B |

41 | 32-52 | 600 | 45-55 | 437 | 90-150 |

|

TSH-40B |

41 | 32-52 | 600 | 45-55 | 437 | 150-220 |

|

TSE-5 0 B |

50.5 | 32-52 | 500 | 45-55 | 430 | 180-270 |

|

TSH-52B |

51.5 | 32-60 | 600 | 90-132 | 682 | 270-400 |

|

TSE-65B |

62.4 | 32-64 | 600 | 90 | 716 | 250-360 |

|

TSH-65B |

62.4 | 32-64 | 600-800 | 110-160 | 875 | 350-500 |

|

TSE-75B |

71 | 32-64 | 600 | 132 | 1050 | 350-500 |

|

TS H -75 B |

71 | 32-64 | 600-800 | 200-250 | 1365 | 600-800 |

|

TSE-95B |

93 | 32-64 | 600 | 315 | 2560 | 800-1200 |

|

TSH-95B |

93 | 32-64 | 600-800 | 400-450 | 2506 | 1200-1600 |

|

TSE-135 |

133 | 32-64 | 500 | 550 | 7162 | 1500-2250 |

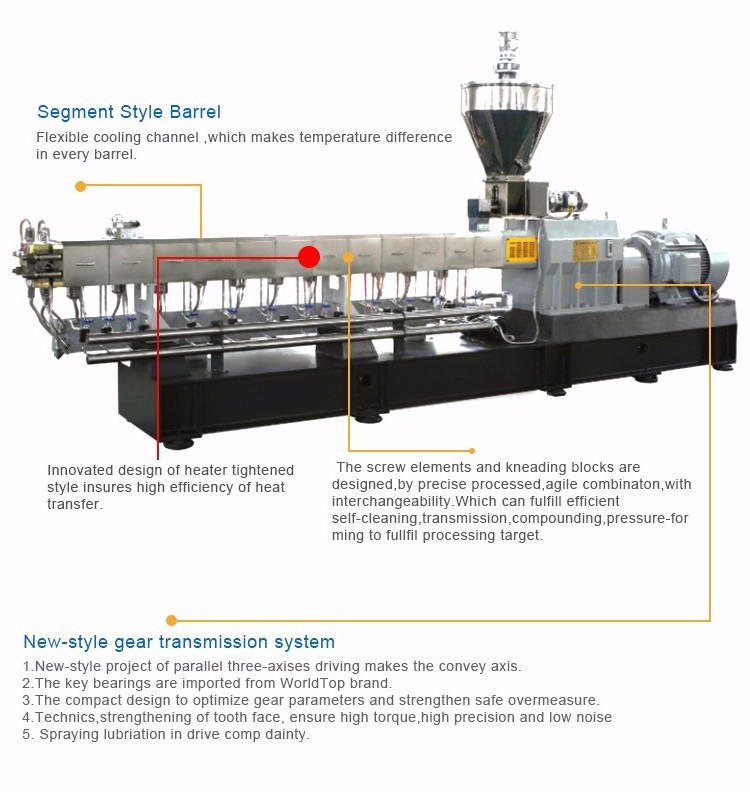

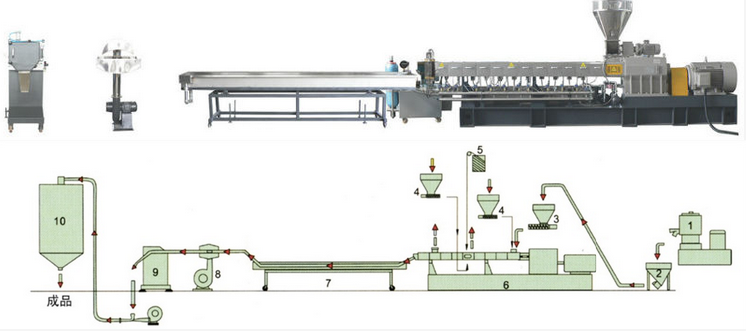

1.

Extruders for Filling/Compoundin, Reinforcing and Recycling

1. High Speed Mixer 2. Loader 3. Main Feeder 4. Side Feeder 5. Long Glass Fiber 6. Twin Screw Extruder 7. Water Tank 8. Air Knife 9. Pelletizer 10. Silo

Fibre reiforcement : glass fibre, carbon fibre reinforced PP, PA, PBT, ABS, PC, POM, PPS, PET, etc.

Fibre reiforcement : glass fibre, carbon fibre reinforced PP, PA, PBT, ABS, PC, POM, PPS, PET, etc.

Incorporation of Fillers: Caco3, Talc, TiO2, carbon black,filled PE, PP, or EVA, etc.

Cable Compounds: cable sheath, cable insulation compounds of LDPE, HDPE, LLDPE, MDPE; radiation-crosslinkable compounds, optical fibre protection compounds, heat-shrinkable polymer compounds.

Special Compounds: PPR pipe compounds, PE compounds for crosslinked pipes, tobacco filter compounds, etc.

High Concentration Color Masterbatches: PE, ABS, PS, EVA, PP,etc. with high concentration of pigments and other processing aids.

Masterbatches with Flame-retardants: PE, ABS, PS, EVA, PET, PP, etc. with flame retardants and other additives

The twin screw s

trand

extruder also fit for PET bottles/ flakes recycling.

2. Water Ring Extruders for Filiing/Compounding/Modificating

1. High Speed Mixer; 2. Main Feeder; 3. Side Feeder; 4. Twin Screw Extruder; 5.Water Ring Pelletizer; 6. Centrifugal Dewaterer; 7. Vibrating Screen; 8. Silo;

Application:

PE, EVA etc. Filled with CACO3,talc,TIO2,carbon black etc.

Cable sheath, cable insulation compoundes of LDPE,HDPE,LLDPE,or MDPE;

Radiation-crosslinkable, heat-shrinkable cable compounds;

PPR pipe compounds, PE compounds for crosslinked pipes;

TPR, TPU thermoplastic elastomers; EVA and hot-melt adhesives;

Color concentrations of PE,ABS, PS,EVA,etc;

Flame retardant master batches of ABS,PS,EVA,etc;

Master batches with PE,PP,PS,etc carriers for degradation applications.

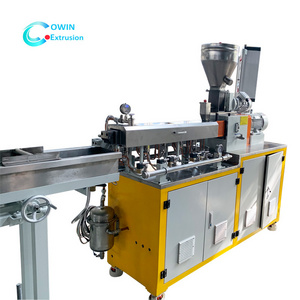

3.Air-cooling Extruders

1.Metering Feeder 2. Extruder 3. Pelletizer 4. Cyclone 5. Vibrating Screen

Application:

Enforcing modification:PE,EVA etc.+CaCo3,Talc, TiO2,Carbon black.

Degradable master batch: PE,PS etc.+starch,additive etc.

Anti-flame master batch: PE, EVA etc.+Sb2O3, Mg(OH)2,AI2(OH)3 etc.

4. Underwater Extruders

1.the main material is PE+CaCO3

2.the metering feeders are equipped with single screw, twin screw, hollow screw, forced feeding ,side-feeding, etc

3.different requirementsof feeding, such as power, pellet, lump and luqid material.

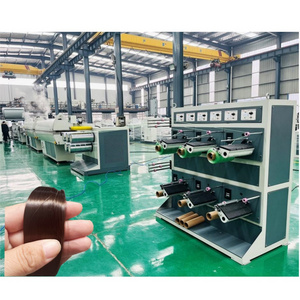

5. Single Screw / Two Stage Single Screw Recycling

Extruder Machine

The single screw extruder fit for clean PP/PE film or PP/PE/ABS flakes recycling, not for compounding masterbatch make.the final end product could be used to make plastic carrying bags or new film.