- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Size II

Quick Details

-

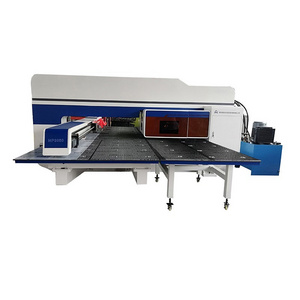

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Guangdong, China

-

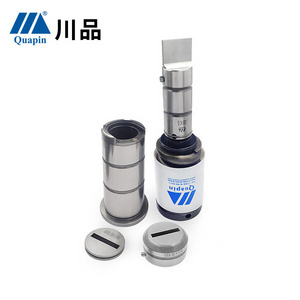

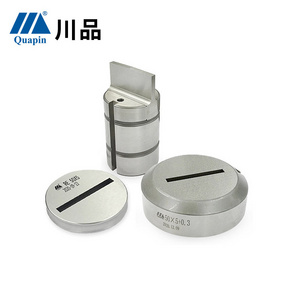

Brand Name:

-

Quapin

-

Model Number:

-

Size II

| Material |

Punch-body SKH51, Die DC53

|

| Heat treatment | HRC 60°- 62° |

| Hits before regrinding ( for stainless steel ) | About 300000 hits |

| Hits before regrinding ( for mild steel ) | About 500000 hits |

| Tool life ( round ) | About 800000 hits |

| Tool life ( shape ) | About 600000 – 700000 hits |

| Delivery time | 3 - 10 Days |

| Forming tools | Cluster Tool, Eko ‘S (Knock Out) Form Up Tool,Emboss Forming Tool,Extrusion Forming Tool, Extrusion Tapping Hole Tool,Bridge Forming Tool,Pedestal (Extrusion & Emboss) Tooling,Louvres Forming Tool,Multi-Scribe Tool,Sheet Marker Tool,Lance And Form Tool,Progressive Rib Tool,Bending Up Tool,Hinge Tool, Wheel Family(Roller Pincher,Roller Shear,Roller Rib ,Roller Offset) Etc... |

| Option | Coating with TICN or Tin |

Notice

The space of holes must be over 3.2mm or 2 fime sheet thickness.

The punching pitch must be bigger than hole size, otherwise will damage the die.

The cluster tool has unitary structure and replacement insert structure, we can design tools according to customer request.

Tools designed as full guide structure when punching holes smaller than 2.0mm.

Must avoid repeat punching of same hole.

The quanfity of punch holes depend on machine's pressure force.

Please provide the following information when you purchase:

CNC punch brand

CNC punch press model

CNC punch die station structure

Thick tower 85 / thick tower 90 / thick tower MATE / thin tower 140 / Murata / thick tower heavy load / bus machine mold series

(Mold height series or the outer diameter of our production data)

The plate material thickness or clearance

Ordering parts: The whole package (eg die / die / back plate, etc.)

Mold Specifications Shape Size: B-RE 30*5 (OB, SQ, RE)

You shoot online transactions, you must provide detailed consignee and address phone, whether urgent.

|

For example 1: AE2510-NT Thick Turret 85 Gap+0.3 Full set B-RE 30*5 |

For example 2: CP1500 Thick Turret 90 Gap+0.25 Punch Assembly D-OB Φ10*50 |

For example 3: EM2510NT I Type Gap+0.3 Upper and lower tooling stripper I-RO Φ15 |

For example 4: M2048TE 114 / Vulcan Gap+0.3 Upper and lower tooling G-SQ 62*62 |

For example 5: Busbar Processing Machine BM303 Copper plate 0.3 Full set B-SQ 20*20 |

We hope that through online activities, to give you a better product and convenient service experience! Have any mold questions, can consult us, we will help you solve the problem the first time!

Tooling Quoted price

Mold height series or the outer diameter of our production data.

Table of recommended die clearance(reference values)

| NCT drive type | Material type / thickness | 0.8 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.2 |

| Hydraulic | Cold-rolled mild steel | 0.15-0.2 | 0.2-0.25 | 0.2-0.25 | 0.40-0.50 | 0.50-0.63 | 0.60-0.75 | 0.64-0.80 |

| Aluminum | 0.15-0.16 | 0.15-0.20 | 0.23-0.30 | 0.30-0.40 | 0.38-0.50 | 0.45-0.60 | 0.48-0.64 | |

| Stainless steel | 0.20-0.24 | 0.25-0.30 | 0.38-0.45 | 0.50-0.60 | 0.53-0.75 | 0.75-0.90 | 0.80-0.96 | |

| Mechanical | Cold-rolled mild steel | 0.15 | 0.15-0.18 | 0.18-0.27 | 0.24-0.36 | 0.30-0.45 | 0.36-0.54 | 0.38-0.58 |

| Aluminum | 0.15 | 0.15-0.16 | 0.15-0.24 | 0.20-0.32 | 0.25-0.40 | 0.30-0.48 | 0.32-0.51 | |

| Stainless steel | 0.15-0.18 | 0.15-0.22 | 0.21-0.33 | 0.28-0.44 | 0.35-0.55 | 0.42-0.66 | 0.45-0.70 |

| 3.5 | 4.0 | 4.5 | 5.0 | 5.5 | 6.0 |

| 0.70-0.88 | 0.80-1.00 | 0.90-1.13 | 1.00-1.25 | 1.10-1.38 | 1.20-1.50 |

| 0.53-0.70 | 0.60-0.80 | 0.68-0.90 | 0.75-1.00 | 0.83-1.10 | 0.90-1.20 |

| 0.88-1.05 | 1.00-1.20 | 1.13-1.35 | - | - | - |

| 0.42-0.63 | 0.48-0.72 | 0.54-0.81 | 0.60-0.90 | 0.66-0.99 | 0.72-1.08 |

| 0.35-0.56 | 0.40-0.64 | 0.45-0.72 | 0.50-0.80 | 0.55-0.88 | 0.60-0.96 |

| 0.49-0.77 | 0.56-0.88 | 0.63-0.99 | - | - | - |

Material Introduction

Punch body material: SKH51

SKH-51, alias high-speed steel, also known as steel or front steel, meaning quenching even in the air can be hardened when cooled, and very sharp. Chong stainless steel, skd series of more conventional mold, toughness and wear resistance are quite different.

Die material: DC53

DC53 is Japan's Datong special steel SKD11 to improve the new cold-work die steel, the technical specifications are contained in the Japanese Industrial Standards (JIS) G4404. It overcomes SKD11 high temperature tempering hardness and lack of toughness weaknesses, will be in the field of general and precision molds SKD11 fully replace the high strength and toughness of common cold die steel.