- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

6000 KG

-

Product name:

-

Corrugated carton box making machine

-

Application:

-

Carton rotary die cutting

-

Keywords:

-

Rotary die cut Packaging

-

Material:

-

carton

-

Type:

-

Semi-auto or full auto

-

Driven Type:

-

Electric

-

Raw material:

-

Cast iron

-

Box type:

-

Special Standard Carton

-

Color:

-

Any color

-

Name:

-

High Speed Printing Slotting Die-cutting Machine Manufacturer

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V/380V 50/60HZ

-

Dimension(L*W*H):

-

As the model

-

Weight:

-

6000 KG

-

Product name:

-

Corrugated carton box making machine

-

Application:

-

Carton rotary die cutting

-

Keywords:

-

Rotary die cut Packaging

-

Material:

-

carton

-

Type:

-

Semi-auto or full auto

-

Driven Type:

-

Electric

-

Raw material:

-

Cast iron

-

Box type:

-

Special Standard Carton

-

Color:

-

Any color

-

Name:

-

High Speed Printing Slotting Die-cutting Machine Manufacturer

-

Marketing Type:

-

Ordinary Product

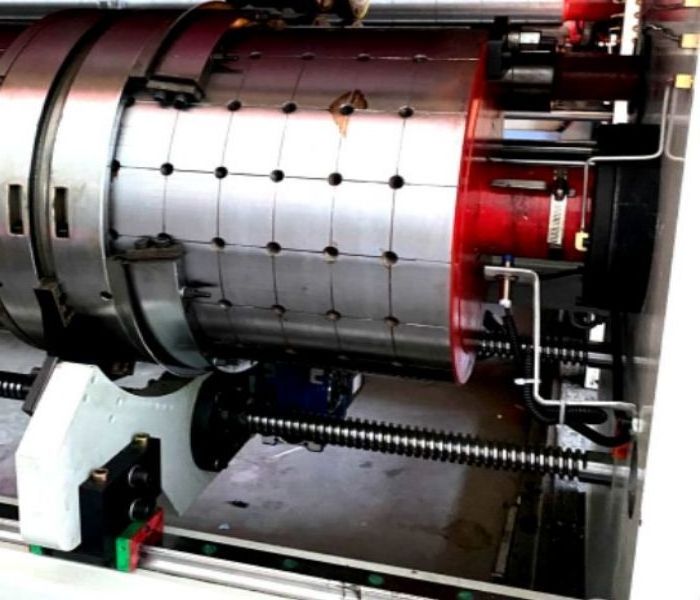

Product Description

|

Model

|

YG 1426

|

|

|

Width

|

3100 mm

|

|

|

The feeding type

|

Chain type

|

|

|

The feeding size

|

350-2600mm

|

|

|

The height of box

|

100-700mm

|

|

|

The Max. depth of slotting

|

350mm

|

|

|

The min. length of box

|

260mm

|

|

|

The min. width of box

|

110mm

|

|

|

Range of upper scoring roller up and down

|

12mm

|

|

|

Speed

|

60P/Min

|

|

|

The Dia. of slotting disc

|

480MM

|

|

|

The thickness of the wall

|

HT 250

|

|

|

The thickness of the gear

|

20GrMnTi

|

|

|

The thickness of the cardboard

|

2-11mm

|

|

|

Weight

|

7.8t

|

|

|

Dimensions

|

4600*4800mm

|

|

|

Please contact me for more models

|

|

|

Product Feature

carton box making machine

1.Cast iron of good anti-seismic performance with the thickness of 60mm is used for the wall of the machine to ensure steady transmission and accurate joint of the gears. It is processed and finished by the high precision machining center at a time, to increase the accuracy. The accurate level gauge is used to adjust when installing the machine.

2.Good quality of steel is used for all the transmission shafts and rolls, high precision dynamic balance adjustment to ensure the steady transmission; All the transmission shafts and rolls are polished and plated hard chrome to make sure of the durability.

3.All the driving gears adopt high quality low carbon alloy steel(20CrMnTi), the teeth are ground and the tooth width reach 60mm.

4.Connect collars with no bonds are used for the whole machine to eliminate clearance, fit for high speed printing. And for the key transmitting parts.

5.Spraying circulation is adopted to lubricate the gears, two oil pumps, and circulating oil supply, self-poise of the level of oil. There is no need to let out the oil, and no leaking of oil will happen.

6.Electric separation and unite of the sections of the machine. Pneumatic lock, auto brake when separate to guarantee no printing dislocation.

7.The alarm rings continuously when the machine moves to ensure safety of the workers.

8.PLC, multifunction touching screen frequency converter control of the phase adjustment in the printing section, die cutting section. Easy to operate and control.

Product Details

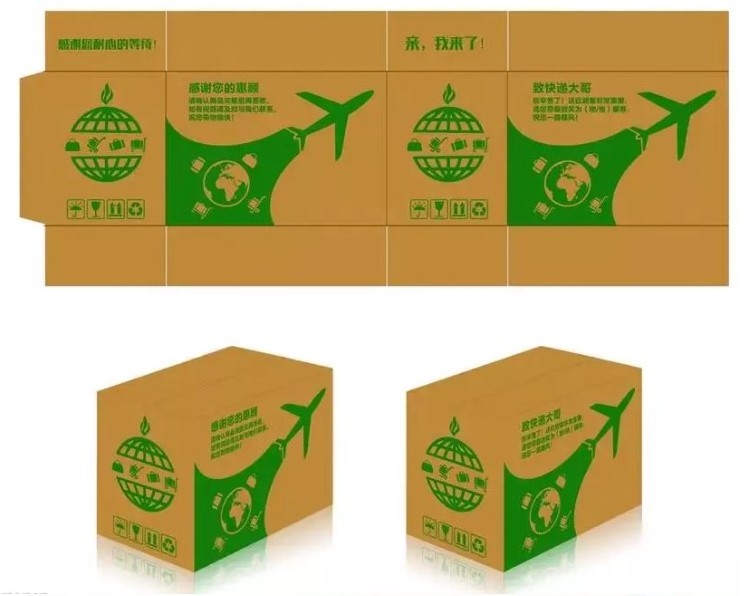

Finished Product

Packing & Delivery

Nude packing

Delivery by shipping

Hot Searches