- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Canroon

-

Dimension(L*W*H):

-

262.4*304*545mm

-

Weight:

-

22 KG

-

name:

-

Canroon CR2000 low price induction heater machine

-

application:

-

welding preheat, PWHT, joint anti-corrosion coating,shrink fitting

-

input power:

-

5-160kw

-

heating temperature:

-

788℃

-

duty cycle:

-

100%

-

dimension:

-

different

-

Frequency:

-

50-60Hz

-

suitable fields:

-

oil and gas pipeline construction, offshore platform construction,

-

IP rating:

-

IP54

-

inductor types:

-

C-type, split-core type,plate type,blanket type, or customize for you

Quick Details

-

Type:

-

Induction Heater

-

Power Source:

-

Electric

-

Voltage:

-

380v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Canroon

-

Dimension(L*W*H):

-

262.4*304*545mm

-

Weight:

-

22 KG

-

name:

-

Canroon CR2000 low price induction heater machine

-

application:

-

welding preheat, PWHT, joint anti-corrosion coating,shrink fitting

-

input power:

-

5-160kw

-

heating temperature:

-

788℃

-

duty cycle:

-

100%

-

dimension:

-

different

-

Frequency:

-

50-60Hz

-

suitable fields:

-

oil and gas pipeline construction, offshore platform construction,

-

IP rating:

-

IP54

-

inductor types:

-

C-type, split-core type,plate type,blanket type, or customize for you

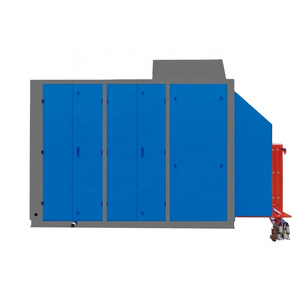

CR2000 Low Price Induction Heater Machine For Steel Pipes Welding Preheat PWHT Joint Coating

Brief introduction of Canroon CR2000 low price induction heater machine for steel pipes welding preheat PWHT joint coating etc:

Induction heating is a method to heat workpieces by generating eddy current inside through electromagnetic induction.Thanks to its advantages, this equipment is widely used for PWHT(post welding heat treatment), welding preheat, joint anti-corrosion coating, shrink fitting, etc, mainly in oil and gas pipeline construction and offshore platform construction.

Overall pictures of Canroon CR2000 low price induction heater machine:

Working site of Canroon CR2000 series low price induction heater machine for steel pipes welding preheat, PWHT, joint coating, shrink fitting, etc:

· Friendly Interface and Accurate Control

The control board offers various parameters for setting so the heating process can be controlled precisely by giving value to temperature, time, heating rate, cooling rate, etc.

· Various Control Mode

The interface offers two basic control modes to choose including temperature control and power control . The former one has 4 modes of preheat , bake-out , PWHT , custom . The last one has 2 modes of constant power and power VS time . Each mode offers different parameters to set. Thus brings the benefit of wide applicability and precise control.

· Fault Record

Fault codes will display and be recorded for reference, and system will respond with protection action like shutdown once fault occurs such as open-loop output or short out.

· Easy Maintenance

Due to modular design,the maintenance will be easy and low-cost.

· Self-Diagnosis

Once fault occurs,CR2000 will act with display of fault code,which was detailed explained in the manual book.

· High Efficiency

This uniquely energy-efficient process converts up to 90% of the expended energy into useful heat,and time-to-temperature is faster than conventional processes due to the method of applying heat, reducing cycle time.

· Uniform Heating

The heat is induced within the part itself by alternating electrical current, thus uniform temperature throughout the heating zone is realized.

· Replaceable Heating Inductor

Apart from induction blanket (blanket type inductor), there are multiple heating inductors for choice including induction coil/cable , C-type inductor , plate type inductor , Split-core inductor , O type inductor , all of which are easily dismountable and reconnected to the power source. So the power source can be used for heating workpiece of different size and shape.

All of our machines are carefully packed in wooden case or carton box or as you require, delivery can be by sea, Express, or by air according to your need.

1. keep the quality first and make more products benefit to our customers' need

2.about our Online/Sale service

1)super and solid quality

2)Fast and punctual delivery

3)Standard export package or as customers’ need.

3.After-sale service

1)Assistance to your project

2)Repairing and maintenance if any problem occur in the warranty.

3)Installation and clerks training

4)Spare and wearing parts for free or with big discount

5)Any feedback of machines can be told to us, and we will try our best to support you.

4.Other cooperation service

1)Technology knowledge share

2)Factory building advising

3)Business expansion advising

1. Are you a trading company or manufacturer?

We are manufacturer located in Shenzhen, China, specialized in induction heating power for many years.

2. What's the delivery time for sample and bulk order?

Normally we have stock of the mini and medium items, 1-3 days for sample order, 15-40days for 20 GP and 40HQ quantity.

3. What's your quality guarantee period?

12 months warranty

4. Can I get a lower price if I order large quantities?

Of course. Cheaper price with larger quantity

5. can you customize the machine for us?

Yes, of course, just tell me your detailed requirement, so I can suggest you most suitable project.