- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong,China

-

Precision Rating:

-

P0,P5

-

Product name:

-

Insert Bearing

-

Material:

-

Chrome Steel GCR15

-

Housing material:

-

Stainless Steel AISI304

-

Application:

-

Machinery

-

Feature:

-

Long Life

-

Service:

-

OEM Service

-

Bearing Material:

-

GCr-15 Chrome Steel

-

Package:

-

Original Package

-

Cage:

-

Stainless steel

-

Structure:

-

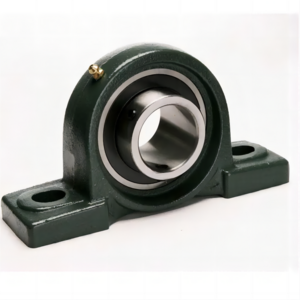

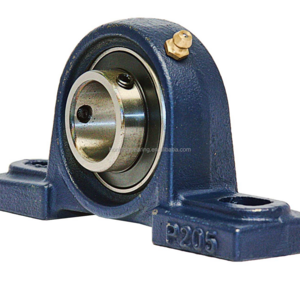

Insert Bearing + Housing

Quick Details

-

Applicable Industries:

-

Machinery Repair Shops, Home Use, Construction works , Energy & Mining, Other

-

Brand Name:

-

Neutral

-

Model Number:

-

SUCP209

-

Place of Origin:

-

Shandong,China

-

Precision Rating:

-

P0,P5

-

Product name:

-

Insert Bearing

-

Material:

-

Chrome Steel GCR15

-

Housing material:

-

Stainless Steel AISI304

-

Application:

-

Machinery

-

Feature:

-

Long Life

-

Service:

-

OEM Service

-

Bearing Material:

-

GCr-15 Chrome Steel

-

Package:

-

Original Package

-

Cage:

-

Stainless steel

-

Structure:

-

Insert Bearing + Housing

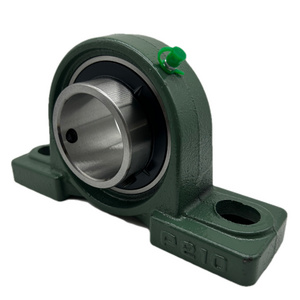

Factory Price Pillow Block Bearing SP 205 UC UCP 205 Stainless Steel Insert Bearing With Housing

Products Description

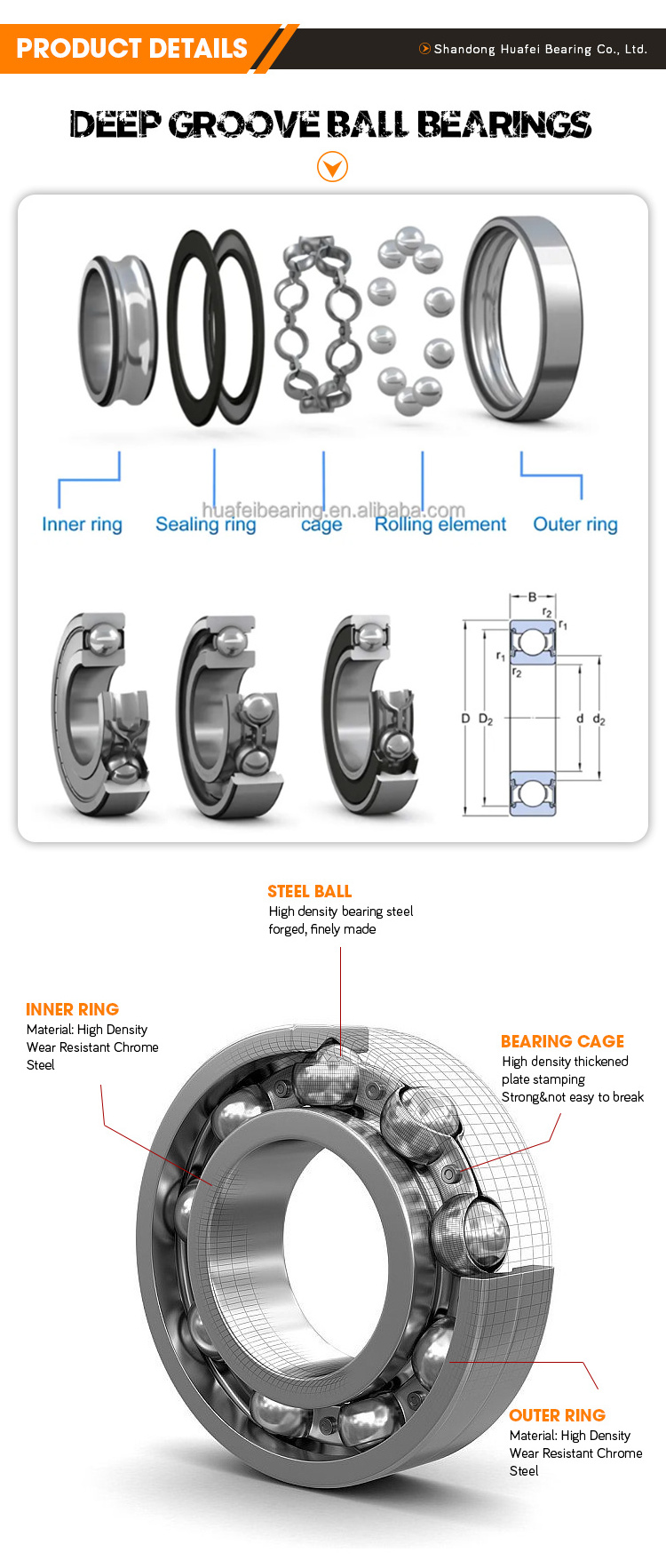

1.Structural Characteristics :

Stainless steel and chrome steel bearing units consist of insert bearings and pillow block bearings. As matching surface of them is spherical, they can compensate the center error through automatic adjustment. Bearings can be classified into four types according to clamping modes with shaft: with set screws; with eccentric locking collars; with tapered bore and fastening adapter sleeve; with concentric locking sleeve. Pillow block bearings can be divided into four types according to material: stainless steel pillow blocks; pressed stamped pillow blocks; znic alloy pillow blocks; plastic pillow blocks. Insert bearings have different sealing methods. According to working conditions, we can choose sealing st ructure to ensure the reliability and guarantee the service life .

Bearing size selection is mainly based on the requirement of load, service life and reliability. Basic rated load is a technical index used to evaluate bearing capacity. Basic rated load includes basic rated dynamic load and basic rated static load. Bearing when it rotates (n > 10 rpm) is characterized as the basic rated dynamic load C. Bearing when it rotates statically or slowly or oscillates (n ≤ 10 rpm) is characterized as the basic rated static load Cor. Outer spherical ball bearing s are centripetal ball bearings, which mainly bear radial force. Therefore, it is characterized by the radial basic rated dynamic load Cr and the radial basic rated static load Cor. The values of the radial basic rated dynamic load Cor and the radial basic rated static load Cor are shown on the product's outline dimension table. Usually, life calculation is an important basis for selecting rolling bearings. Life generally refers to the fatigue life of bearings. When the bearing is used correctly, that is, the load is moderate, the installation is correct and the lubrication is good. The damage of the bearing is mainly caused by the fatigue spalling of the rolling surface caused by alternating contact stress, which is impossible to avoid completely. However, different mechanical uses require different requirements for bearings, which require the bearings to maintain a certain performance during the specified period. After a period of working time, the

noise and vibration increase, the wear and tear result in the decrease of accuracy, and the aging of grease will lead to the failure of the bearing, or can not meet the requirements of this kind of machinery. The life before failure is called noise life, wear life and grease life. In addition to the above-mentioned service life, the reasons why bearings can no longer be used include sintering, fracture, crack, jam, seal failure, etc. These should be regarded as bearing failures. The failure originates from improper selection of bearings, poor mechanical design, installation, use, maintenance and other errors, which should be different from the service life of bearings

3 Lubrication And Working Temperature

3.1 Grease

In the bearings of spherical ball bearings with seat outside, the filling of rust-proof grease conforms to the requirements of GB7324 (lithium-based grease). Our company generally uses industrial grease (Great Wall) and food-grade grease Mobil FM222.

Stainless steel and chrome steel bearing units consist of insert bearings and pillow block bearings. As matching surface of them is spherical, they can compensate the center error through automatic adjustment. Bearings can be classified into four types according to clamping modes with shaft: with set screws; with eccentric locking collars; with tapered bore and fastening adapter sleeve; with concentric locking sleeve. Pillow block bearings can be divided into four types according to material: stainless steel pillow blocks; pressed stamped pillow blocks; znic alloy pillow blocks; plastic pillow blocks. Insert bearings have different sealing methods. According to working conditions, we can choose sealing st ructure to ensure the reliability and guarantee the service life .

2.Bearing Selection :

Bearing size selection is mainly based on the requirement of load, service life and reliability. Basic rated load is a technical index used to evaluate bearing capacity. Basic rated load includes basic rated dynamic load and basic rated static load. Bearing when it rotates (n > 10 rpm) is characterized as the basic rated dynamic load C. Bearing when it rotates statically or slowly or oscillates (n ≤ 10 rpm) is characterized as the basic rated static load Cor. Outer spherical ball bearing s are centripetal ball bearings, which mainly bear radial force. Therefore, it is characterized by the radial basic rated dynamic load Cr and the radial basic rated static load Cor. The values of the radial basic rated dynamic load Cor and the radial basic rated static load Cor are shown on the product's outline dimension table. Usually, life calculation is an important basis for selecting rolling bearings. Life generally refers to the fatigue life of bearings. When the bearing is used correctly, that is, the load is moderate, the installation is correct and the lubrication is good. The damage of the bearing is mainly caused by the fatigue spalling of the rolling surface caused by alternating contact stress, which is impossible to avoid completely. However, different mechanical uses require different requirements for bearings, which require the bearings to maintain a certain performance during the specified period. After a period of working time, the

noise and vibration increase, the wear and tear result in the decrease of accuracy, and the aging of grease will lead to the failure of the bearing, or can not meet the requirements of this kind of machinery. The life before failure is called noise life, wear life and grease life. In addition to the above-mentioned service life, the reasons why bearings can no longer be used include sintering, fracture, crack, jam, seal failure, etc. These should be regarded as bearing failures. The failure originates from improper selection of bearings, poor mechanical design, installation, use, maintenance and other errors, which should be different from the service life of bearings

3 Lubrication And Working Temperature

3.1 Grease

In the bearings of spherical ball bearings with seat outside, the filling of rust-proof grease conforms to the requirements of GB7324 (lithium-based grease). Our company generally uses industrial grease (Great Wall) and food-grade grease Mobil FM222.

3.2 Working Temperature Generally, when the working temperature of bearings does not exceed 100°C and the continuous working temperature of outer spherical ball bearings is above 70 C, it is necessary to consider shortening the re-lubrication period. The low temperature limit is not more than 15 C below zero. If used at high temperature, the reduction of basic rated load caused by this should be considered. At the same time, the radial clearance should be larger than normal. If there is a large temperature difference between the inner ring and the outer ring, the radial clearance should be reasonably determined.

3.3 Relubrication Cycle Usually, the life of grease can meet the probation period of rated life of bearing. Re-lubricated bearings need to be regularly greased to ensure their long life. When bearing is re-lubricated, if different greases are mixed, the lubrication ability will be reduced. So when using different greases, please contact Boren or grease manufacturer

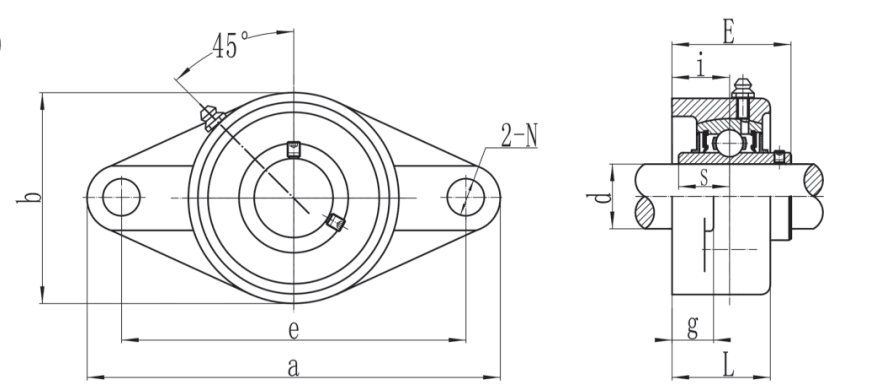

insert bearing with housing model

|

带座轴承型号 Bearing Unit No

|

|

轴径 Bore Dia

|

外形尺寸(毫米) Dimensions(mm)

|

|

|

|

|

|

|

|

d

|

a

|

e

|

i

|

b

|

|

|

|

|

mm

|

|

|

|

|

|

|

SUCFL201

|

|

12

|

99

|

76.2

|

15

|

55

|

|

|

SUCFL201-8

|

|

|

|

|

|

|

|

|

SUCFL202

|

|

15

|

|

|

|

|

|

|

SUCFL202-10

|

|

|

|

|

|

|

|

|

SUCFL203

|

|

17

|

|

|

|

|

|

|

SUCFL203-11

|

|

|

|

|

|

|

|

|

SUCFL204

|

|

20

|

113

|

90

|

15

|

60

|

|

|

SUCFL204-12

|

|

|

|

|

|

|

|

|

SUCFL205

|

|

25

|

130

|

99

|

16

|

68

|

|

|

SUCFL205-14

|

|

|

|

|

|

|

|

|

SUCFL205-15

|

|

|

|

|

|

|

|

|

SUCFL205-16

|

|

|

|

|

|

|

|

|

SUCFL206

|

|

30

|

148

|

117

|

18

|

80

|

|

|

SUCFL206-17

|

|

|

|

|

|

|

|

|

SUCFL206-18

|

|

|

|

|

|

|

|

|

SUCFL206-19

|

|

|

|

|

|

|

|

|

SUCFL206-20

|

|

|

|

|

|

|

|

|

SUCFL207

|

|

35

|

161

|

130

|

19

|

90

|

|

|

SUCFL207-20

|

|

|

|

|

|

|

|

|

SUCFL207-21

|

|

|

|

|

|

|

|

|

SUCFL207-22

|

|

|

|

|

|

|

|

|

SUCFL207-23

|

|

|

|

|

|

|

|

|

SUCFL208

|

|

40

|

175

|

140

|

21

|

100

|

|

|

SUCFL208-24

|

|

|

|

|

|

|

|

|

SUCFL208-25

|

|

|

|

|

|

|

|

|

SUCFL209

|

|

45

|

188

|

148

|

22

|

108

|

|

|

SUCFL209-26

|

|

|

|

|

|

|

|

|

SUCFL209-27

|

|

|

|

|

|

|

|

|

SUCFL209-28

|

|

|

|

|

|

|

|

Ps: This is part model number of

insert bearing with housing

we have, if you are fail to find the one you need, please contact us directly

Product Details

Product Parameter

|

Product name

|

SUCP209 stainless steel insert bearing with housing

|

|

Place of origin

|

Shandong,China

|

|

Product Brand

|

Neutral

|

|

Technics

|

automation

|

|

delivery date

|

3-10 days in stock if oem,it needs ti be negotiated

|

|

warranty

|

1 Year

|

Product Category

Hot Searches