- Product Details

- {{item.text}}

Quick Details

-

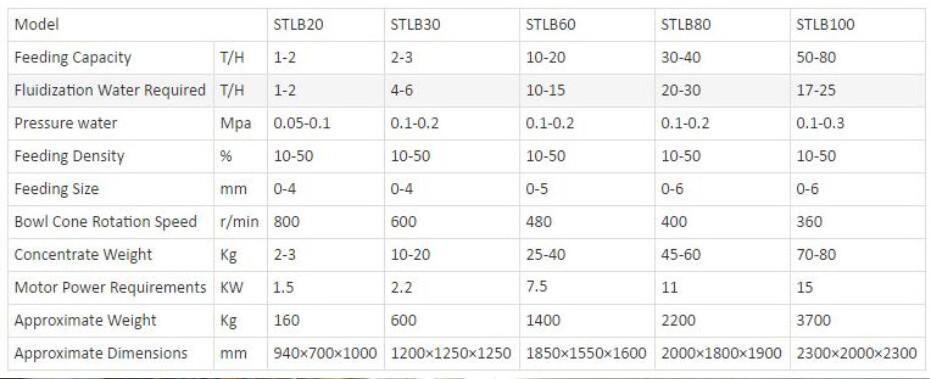

Voltage:

-

220V-480V

-

Dimension(L*W*H):

-

940x700x1000

-

Weight:

-

1300 KG

-

Product name:

-

Centrifugel gold concentrator

-

Application:

-

Gold

-

Capacity(t/h):

-

40-60

-

Feeding size(mm):

-

0-4

-

Cone rotation speed (r/min):

-

460

-

Concentrates capacity(kg/time):

-

60-70

-

Slurry density(%):

-

0-50

-

Pressure water required(Mpa):

-

0.16

-

Factory visit:

-

welcome

-

Color:

-

Customers' Requirements

Quick Details

-

Production Capacity:

-

99%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

The Nile

-

Voltage:

-

220V-480V

-

Dimension(L*W*H):

-

940x700x1000

-

Weight:

-

1300 KG

-

Product name:

-

Centrifugel gold concentrator

-

Application:

-

Gold

-

Capacity(t/h):

-

40-60

-

Feeding size(mm):

-

0-4

-

Cone rotation speed (r/min):

-

460

-

Concentrates capacity(kg/time):

-

60-70

-

Slurry density(%):

-

0-50

-

Pressure water required(Mpa):

-

0.16

-

Factory visit:

-

welcome

-

Color:

-

Customers' Requirements

Product Description

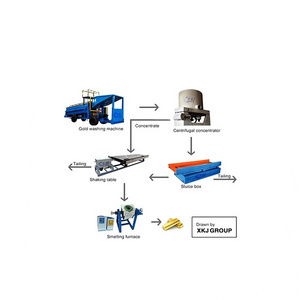

Gold centrifugal concentrator gold concentrator table alluvial gold processing plant

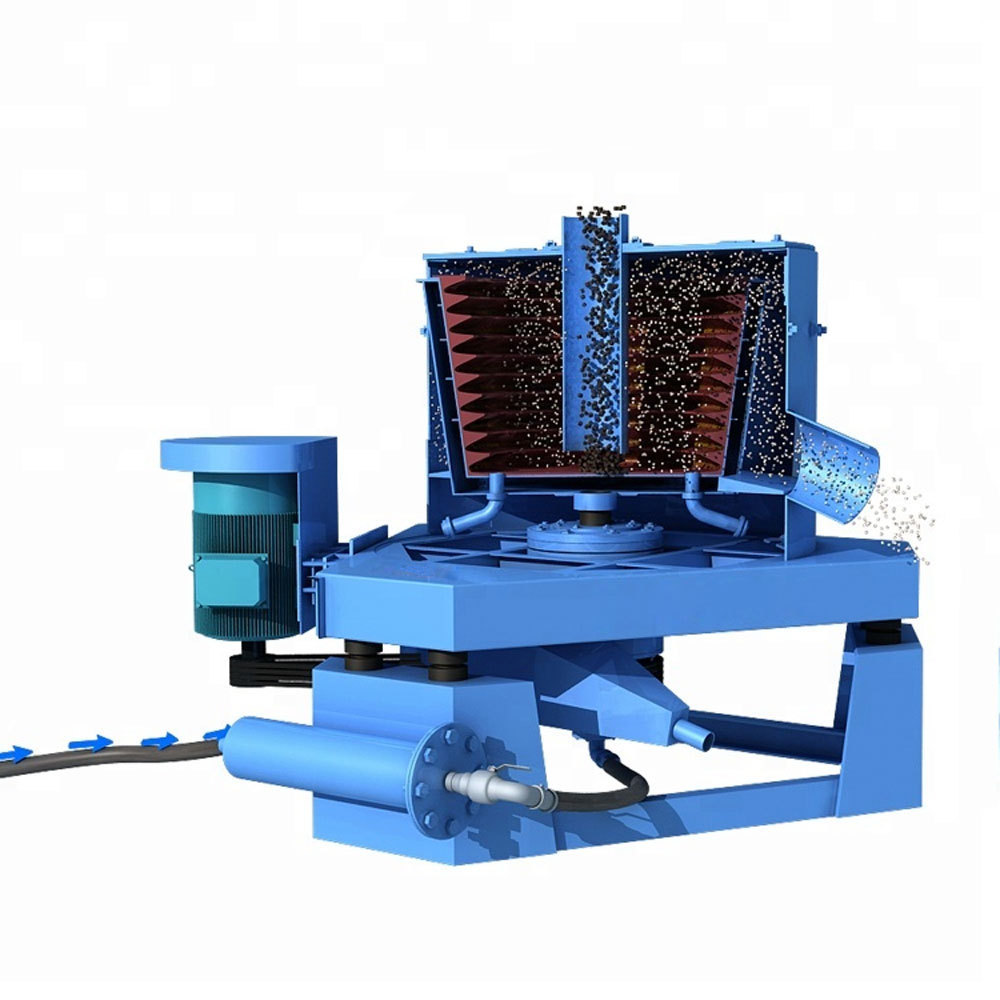

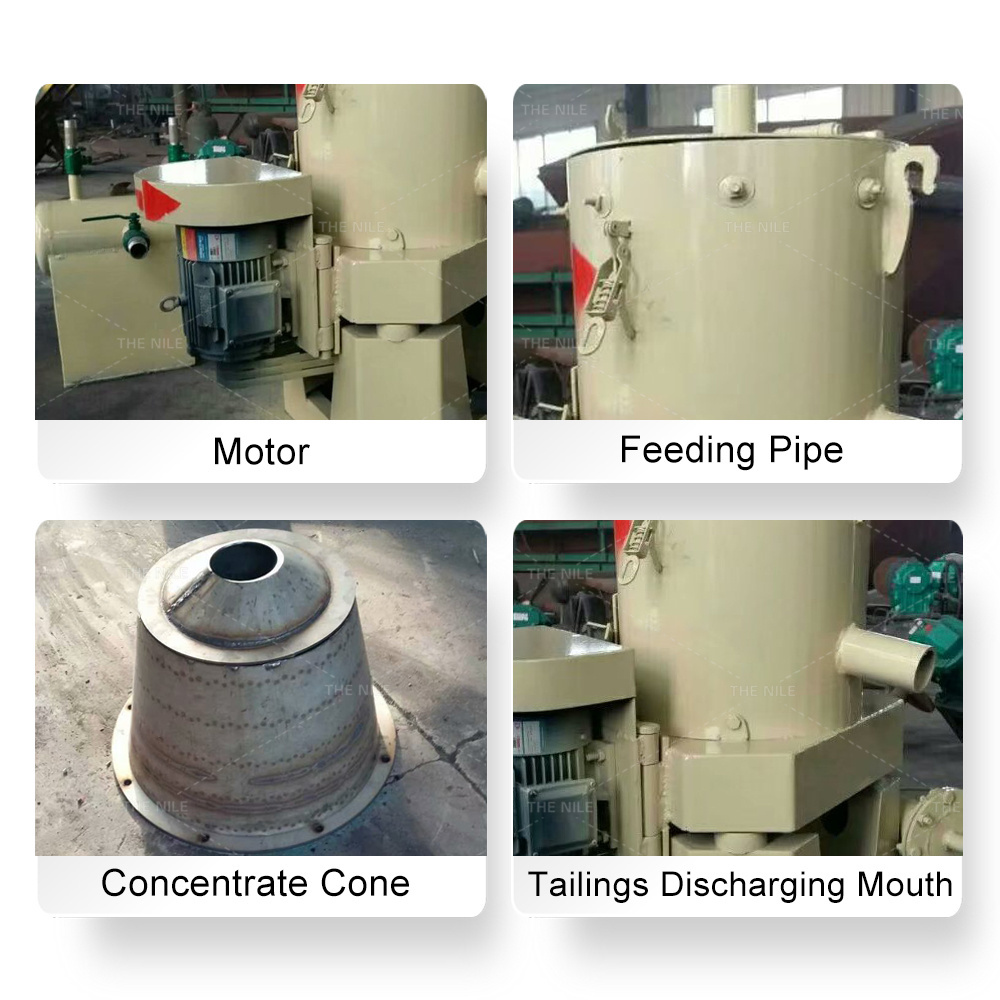

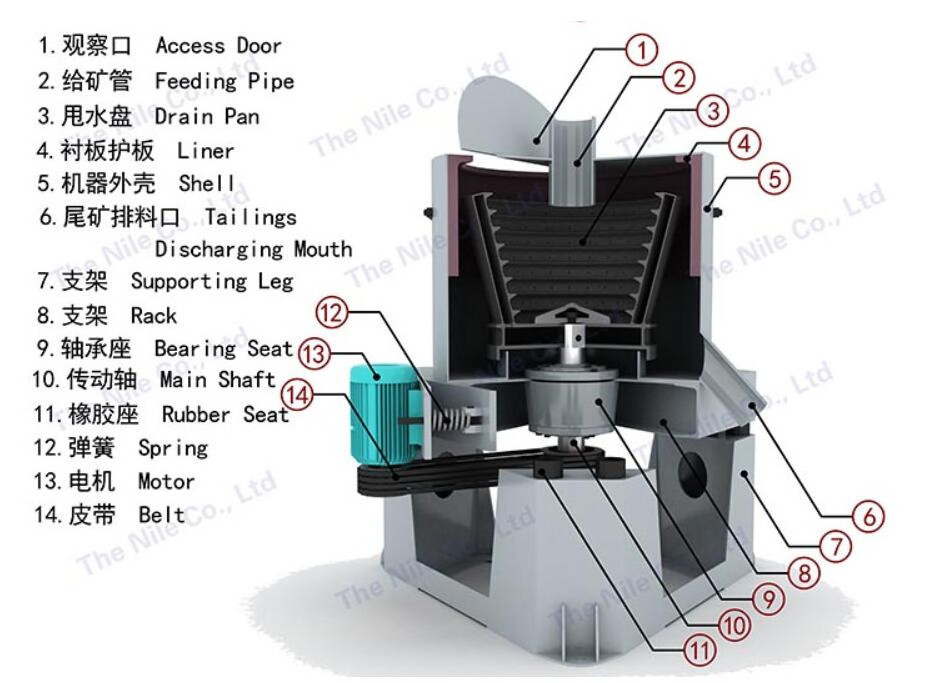

gold centrifugal concentrator gold concentrator table alluvial gold processing plant is a relatively new type of gravity concentration apparatus. The machines utilise the principles of a centrifuge to enhance the gravitational force experienced by feed particles to effect separation based on particle density. The key components of the unit are a cone shaped "concentrate" bowl, rotated at high speed by an electric motor and a pressurized water jacket encompassing the bowl. Feed material, typically from a ball mill discharge or cyclone underflow bleed, is fed as a slurry toward the centre of the bowl from above. The feed slurry contacts the base plate of the vessel and due to its rotation, is thrust outward. The outer extremities of the concentrate bowl house a series of ribs and between each pair of ribs is a groove. During operation the lighter material flows upward over the grooves and heavy mineral particles (usually of economic value) become trapped within them. Pressurized water is injected through a series of tangential water inlets along the perimeter of each groove to maintain a fluidized bed of particles in which heavy mineral particles can be efficiently concentrated.

Technical Data

Our Advantages

15 years experience

Gantry 5's administrative interface has been completely.

Quality guarantee

The admin provides multiple options for styles, layout, particles.

24-hour service

Salient is built with a responsive layout, which means it automatically.

Contact

Looking forward to have a cooperation with you !

Contact us anytime if you free

Whatsapp:+86-15137168510

Telephone:+86-371-6330 3268

Hot Searches