- Product Details

- {{item.text}}

Quick Details

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

1 - 2 mm

-

Heating Power (kW):

-

7 kW

-

Air Comsumption(L/min):

-

3 L/min

-

Water Comsumption(L/min):

-

50 L/min

-

Place of Origin:

-

Zhejiang, China

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

13500*6000*3300

-

Weight (T):

-

4.5 T

-

Power(W):

-

98KW

-

Marketing Type:

-

Hot Product 2019

-

Certification:

-

CE

-

After Warranty Service:

-

Video technical support

Quick Details

-

Max.Forming Height(mm):

-

200 mm

-

Forming Width (mm):

-

530 mm

-

Forming Length (mm):

-

350 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

1 - 2 mm

-

Heating Power (kW):

-

7 kW

-

Air Comsumption(L/min):

-

3 L/min

-

Water Comsumption(L/min):

-

50 L/min

-

Place of Origin:

-

Zhejiang, China

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

13500*6000*3300

-

Weight (T):

-

4.5 T

-

Power(W):

-

98KW

-

Marketing Type:

-

Hot Product 2019

-

Certification:

-

CE

-

After Warranty Service:

-

Video technical support

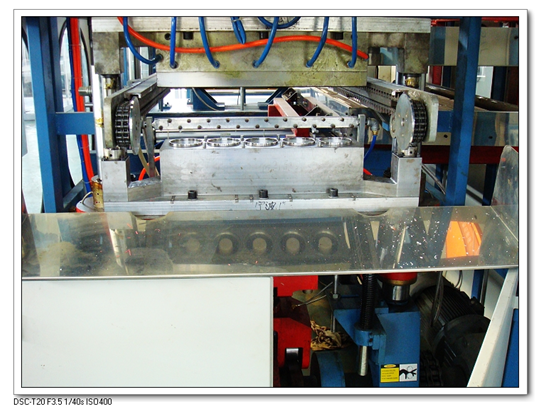

Plastic cup making machine

Product Description:

This machine is mainly used for the production of disposable plastic containers: such as cups, drink cups, jelly cups, yogurt cups, packing bowls, noodle bowls, plastic cup lids, boxes, fruit trays and medicine, light industry, textiles. , Travel, toys and other related plastic packaging products.

Features:

1. High efficiency, energy saving, safety and environmental protection, product qualified rate.

2. The whole set of sheet feeding, heating, stretching, forming, trimming, blowing glass, waste rewinding time to complete, saving labor costs, improved product margins.

3. Stable operation, low noise, clamping strong, high yield and so on.

4. Machine is controlled by PLC touch screen, easy operation, steady cam running durable, production speedy; by installing different molds can produce different plastic products, reached a multi-purpose machine.

5. Accommodate a wide range of raw materials, such as PS, PP, PVC, PET, ABS and other plastic sheet can manufacture.

Technical Parameter:

|

Forming Area ( mm 2 ) |

650×350 |

|

Sheet width ( mm ) |

500 – 660 |

|

Sheet thickness ( mm ) |

0.3-2.0 |

|

Power consumption ( kw ) |

±30 |

|

Forming depth ( mm ) |

160 |

|

Machine Speed ( p/min ) |

15-35 |

|

Use pressure ( mpa ) |

0.7 |

|

Water consumption ( m 3 /h ) |

0.5 |

|

Host rated power ( kw ) |

5.5 |

|

Dimensions (L x W x H) (m) |

3.5×1.8×2.5 |

|

Total weight |

4500kg |

|

Power input |

380V±15V |