- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Junbond

-

Model Number:

-

JB9700

-

Type:

-

Neutral Silicone Sealant

-

Product name:

-

Neutral Silicone Sealant

-

Feature:

-

Fast Dry/No Toxic

-

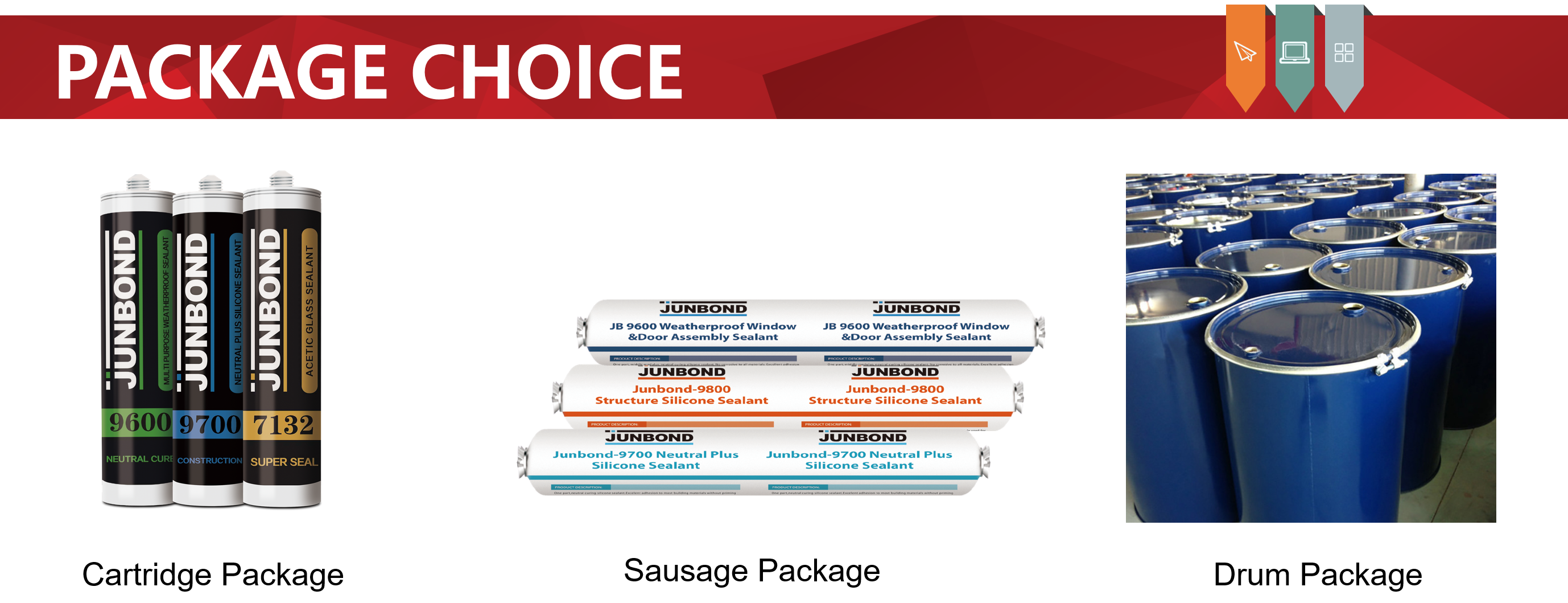

Package:

-

Cartridge/Sausage/Drum

-

Cartridge:

-

300ml

-

Sausage:

-

590ml

-

Drum:

-

200L

-

Shelf life:

-

12 Months

-

Color:

-

White

-

Sample:

-

Free

-

Certificate:

-

ISO9001/ISO14001

Quick Details

-

CAS No.:

-

9009-54-5

-

Other Names:

-

Silicone Sealant

-

MF:

-

Mixture

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Junbond

-

Model Number:

-

JB9700

-

Type:

-

Neutral Silicone Sealant

-

Product name:

-

Neutral Silicone Sealant

-

Feature:

-

Fast Dry/No Toxic

-

Package:

-

Cartridge/Sausage/Drum

-

Cartridge:

-

300ml

-

Sausage:

-

590ml

-

Drum:

-

200L

-

Shelf life:

-

12 Months

-

Color:

-

White

-

Sample:

-

Free

-

Certificate:

-

ISO9001/ISO14001

Junbond manufacture white grey black silicone sealant drum for kitchen uae glass sealant silicone for filling machine

Product Feature:

One-component, neutral curing silicone sealant. Excellent adhesion to most building materials without priming, and can be used at

all kinds of weather. Sealant becomes elastomer after curing which Permits joint movement up to ±35% from original joint width.

Main Application:

1. Weatherproof sealing for curtain wall projects.

2. Sealing of indoor and outdoor decoration works.

3. Install glass and frame edge anti-seepage sealing for building doors and windows.

4. Sealing of aluminum composite panel engineering construction.

5. Other construction and industrial purposes.

How to use:

1. Before construction, a test of the adhesion of the sealant to the substrate should be carried out to confirm the suitability

of the product.

2. The substrate should be thoroughly cleaned with solvent or suitable cleaning agent, kept dry and glued within 30 minutes

after cleaning.

3. When gluing, ensure that the gap is completely filled, so that the gluing layer is dense and in close contact with the

surface of the substrate, and the gluing gap should be repaired within 5 minutes after gluing.

4. Suitable application temperature range 5°C to 40°C.

Warnings:

1. Use in a well-ventilated environment.

2. Use solvents in accordance with the appropriate safety regulations.

3. Keep the product out of the reach of children.

4. If uncured sealant melts your eyes, wash them immediately with water or seek medical attention.

Executive Standard: JC/T 485-2007

One-component, neutral curing silicone sealant. Excellent adhesion to most building materials without priming, and can be used at

all kinds of weather. Sealant becomes elastomer after curing which Permits joint movement up to ±35% from original joint width.

Main Application:

1. Weatherproof sealing for curtain wall projects.

2. Sealing of indoor and outdoor decoration works.

3. Install glass and frame edge anti-seepage sealing for building doors and windows.

4. Sealing of aluminum composite panel engineering construction.

5. Other construction and industrial purposes.

How to use:

1. Before construction, a test of the adhesion of the sealant to the substrate should be carried out to confirm the suitability

of the product.

2. The substrate should be thoroughly cleaned with solvent or suitable cleaning agent, kept dry and glued within 30 minutes

after cleaning.

3. When gluing, ensure that the gap is completely filled, so that the gluing layer is dense and in close contact with the

surface of the substrate, and the gluing gap should be repaired within 5 minutes after gluing.

4. Suitable application temperature range 5°C to 40°C.

Warnings:

1. Use in a well-ventilated environment.

2. Use solvents in accordance with the appropriate safety regulations.

3. Keep the product out of the reach of children.

4. If uncured sealant melts your eyes, wash them immediately with water or seek medical attention.

Executive Standard: JC/T 485-2007

|

No

|

Test Item

|

|

Unit

|

Actual results

|

|

|

1

|

Appearance

|

|

-

|

Smooth, no air bubbles, no lumps

|

|

|

2

|

Tack free time(at what % humidity)

|

|

min

|

10

|

|

|

3

|

Slump

|

Vertical

|

mm

|

0

|

|

|

|

|

Horizontal

|

mm

|

Not deformed

|

|

|

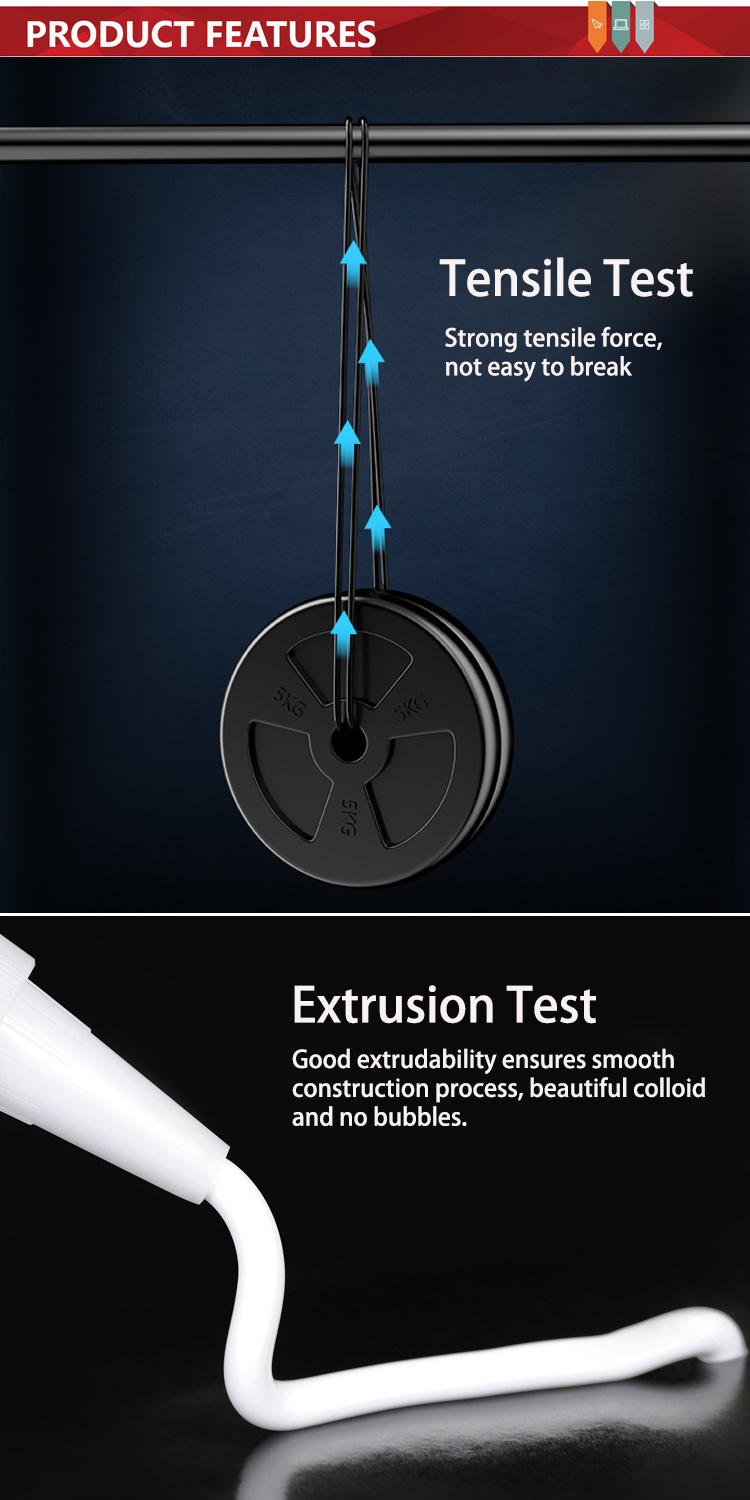

4

|

Extrusion

|

|

ml/min

|

515

|

|

|

5

|

Shore A hardness /72h

|

|

-

|

37

|

|

|

6

|

Shrinkage

|

|

%

|

/

|

|

|

7

|

Effect of heat aging on

|

|

-

|

|

|

|

|

- Weight loss

|

|

%

|

3.5%

|

|

|

|

- Cracking

|

|

-

|

No

|

|

|

|

- Chalking

|

|

-

|

No

|

|

|

8

|

Tensile adhesion

|

|

Mpa

|

|

|

|

|

- Standard condition

|

|

|

0.84

|

|

|

|

- Immersion in water

|

|

|

/

|

|

|

|

- Dry at 100°C

|

|

/

|

|

|

|

9

|

Elongation at break

|

|

193%

|

293

|

|

|

10

|

Specific gravity

|

|

g/cm3

|

1.5

|

|

|

11

|

Completely dry

|

|

hours

|

30

|

|

|

12

|

Temperature Resistence

|

|

°C

|

-50℃~150℃

|

|

|

13

|

Application Temperature

|

|

°C

|

4℃~40℃

|

|

|

14

|

Color

|

|

|

Black

|

|

Hot Searches