- Product Details

- {{item.text}}

Quick Details

-

Extra Services:

-

Welding / Brazing

-

Power:

-

CNC

-

Certification:

-

ce

-

Machine Type:

-

Coiling Bending Machine

-

Raw Material:

-

Sheet / Plate Rolling

-

Application:

-

CNC bending machine

Quick Details

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

QUESTT

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Extra Services:

-

Welding / Brazing

-

Power:

-

CNC

-

Certification:

-

ce

-

Machine Type:

-

Coiling Bending Machine

-

Raw Material:

-

Sheet / Plate Rolling

-

Application:

-

CNC bending machine

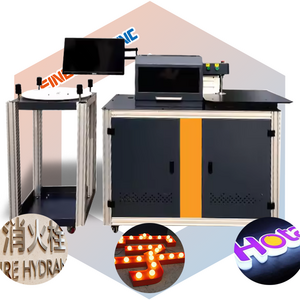

F e a tures:

a) U ser-friendly interface, simple operation through LCD touch screen only;

b) P a t ented notching blade, milling processing technology, no spark, no dust, slotting surface is smooth & bright;

c) H igh precision & one-time notching for materials with different thickness;

d) Single-side notching can fully meet all metal strips;

e) M u ch more Simplified, functional and competitive price.

f) D e m o V ideo available; Custom-made available.

g) C E Certificate available; Material available.

T echnical Parameters:

|

Mode l |

QUESTT-SB Channel letter bending machine |

|

Function |

Bending and single-side notching |

|

Range |

F o r making sidewalls of sign letters |

|

Applicable Materials |

Stainless steel strips, iron strips, aluminum strips, galvanized coil…etc. |

|

M a t e ri a l thickness |

Stainless Steel: 0.4 ~ 1.0 mm Iron/Aluminum: 0.4 ~ 1.2mm |

|

M a t e ri a l width |

1 0 ~ 150mm |

|

B end i n g radius |

≥ 5 m m |

|

F e e d i n g speed |

10 ~ 4 0M /M IN |

|

B end i n g Motor |

Step motor |

|

P owe r |

1 .7KW |

|

V o l t a g e |

A C220V, 50HZ |

|

Air Pressure |

0 .6~0.8MPA |

|

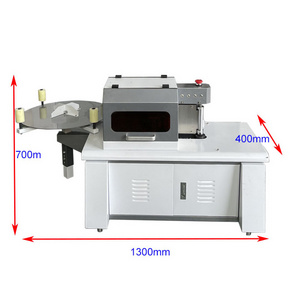

S i z e |

1 6 00 *8 00 *1 5 50 m m |

|

W e ig h t |

4 5 0 K G |

|

Precision |

0 .05mm |

|

S o ftware |

Questt software |

|

I npu t file format |

.plt |

|

C o mmunication port |

USB |

|

O pe r a tion Interface |

T o u ch screen |

|

P a c k a gi n g Details |

2 wooden boxes: 1.35m*1.1m*1.7m + 0 .85m*0.85m*1.3m = 3.46cbm |

Service Promise:

We persist in customer-oriented strategy to provide customers with satisfactory pre-sale and after-sale service of training and maintenance etc.

1 . Pre-sale Service

Ø B ef ore signing the contract, our company will offer various proposals of production process, the technical consultation, testing samples, selection of equipment models etc

2 . Free training for clients’ staff in our factory on:

Ø C ommon operation of the machine & software;

Ø B asic maintenance and cleaning;

Ø Solutions to common hardware & software malfunction;

3. On-site Technical Support:

Ø If clients need on-site installation assistance, clients shall bear the relevant costs including visa, hotel, transportation and accommodation.

4. Warranty:

Ø One year guarantee period for the whole machine.

Ø Free replacement spare parts in warranty period, freight on your side.

Ø Software is upgraded for free within one year.