- Product Details

- {{item.text}}

Quick Details

-

Type:

-

Seafood drying machine

-

Voltage:

-

220VAC/50Hz

-

Power:

-

9.8kW

-

Weight:

-

200 KG

-

Dimension(L*W*H):

-

2115.5 x 1050 x 2352mm

-

Product name:

-

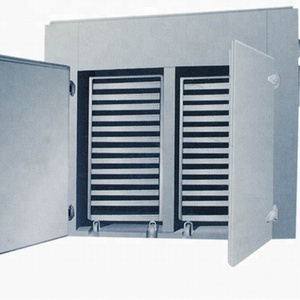

Cold&hot air drying machine

-

Model:

-

JDZN-CHDM-3P

-

Material:

-

SUS304/color steel

-

Volatge:

-

220VAC/50Hz

-

Dehumidification:

-

9kg/h

-

Rated heating capacity:

-

9.8kW

-

Rated/max input power:

-

4.3kW/10.4kW

-

Rated/max running current:

-

21.6A/42.1A

-

Electriicty heater+max input power:

-

10.4kW

-

Drying temperure range:

-

5-70C

Quick Details

-

Marketing Type:

-

Hot product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

JDZN

-

Type:

-

Seafood drying machine

-

Voltage:

-

220VAC/50Hz

-

Power:

-

9.8kW

-

Weight:

-

200 KG

-

Dimension(L*W*H):

-

2115.5 x 1050 x 2352mm

-

Product name:

-

Cold&hot air drying machine

-

Model:

-

JDZN-CHDM-3P

-

Material:

-

SUS304/color steel

-

Volatge:

-

220VAC/50Hz

-

Dehumidification:

-

9kg/h

-

Rated heating capacity:

-

9.8kW

-

Rated/max input power:

-

4.3kW/10.4kW

-

Rated/max running current:

-

21.6A/42.1A

-

Electriicty heater+max input power:

-

10.4kW

-

Drying temperure range:

-

5-70C

Products Description

How heat pumps work?

A heat pump is a heat transfer device. It utilizes the effects of freon's compression, liquefaction and heat absorption and

throttling expansion to transfer heat energy from a low temperature environment to a high temperature environment, so that the high temperature environment can obtain heat efficiency, which is much higher than any other heating method several times.There is heat exchange and water molecule exchange between wet materials and air. According to Dalton's drying formula, the drying speed of materials is proportional to the temperature difference between the dry and wet bulbs of the air, so the air source heat pump that can provide drier air can be more efficient. Efficiently complete the drying process.

A heat pump is a heat transfer device. It utilizes the effects of freon's compression, liquefaction and heat absorption and

throttling expansion to transfer heat energy from a low temperature environment to a high temperature environment, so that the high temperature environment can obtain heat efficiency, which is much higher than any other heating method several times.There is heat exchange and water molecule exchange between wet materials and air. According to Dalton's drying formula, the drying speed of materials is proportional to the temperature difference between the dry and wet bulbs of the air, so the air source heat pump that can provide drier air can be more efficient. Efficiently complete the drying process.

Working process

1. Endothermic compression process

The compressor drives the refrigerant cycle, uses the refrigerant as a carrier, absorbs free heat energy from the evaporator,

compresses the compressor to do work, and becomes a high-temperature and high-pressure refrigerant.

2. Exothermic condensation process

The high-temperature refrigerant transformed by the endothermic compression process is circulated to the condenser to release heat, and then the heat is brought to the drying room by the circulating fan as the heat required for drying

3. Dehumidification process

As the temperature in the drying room rises, the moisture in the drying materials will gradually evaporate, and then the fresh air humidity removal system will dehumidify, or the evaporator will condense the moisture in the drying room to dehumidify, and remove the moisture in the drying room. The moisture in the material is exhuasted repeatly in this way, so as to achieve the effect of drying the material.

1. Endothermic compression process

The compressor drives the refrigerant cycle, uses the refrigerant as a carrier, absorbs free heat energy from the evaporator,

compresses the compressor to do work, and becomes a high-temperature and high-pressure refrigerant.

2. Exothermic condensation process

The high-temperature refrigerant transformed by the endothermic compression process is circulated to the condenser to release heat, and then the heat is brought to the drying room by the circulating fan as the heat required for drying

3. Dehumidification process

As the temperature in the drying room rises, the moisture in the drying materials will gradually evaporate, and then the fresh air humidity removal system will dehumidify, or the evaporator will condense the moisture in the drying room to dehumidify, and remove the moisture in the drying room. The moisture in the material is exhuasted repeatly in this way, so as to achieve the effect of drying the material.

Product Paramenters

|

Machine name

|

Cold&hot air drying machine

|

|

Model

|

JDZN-CHDM-3P

|

|

Volatge

|

220VAC/50Hz

|

|

Dehumidification

|

9kg/h

|

|

Rated heating capacity

|

9.8kW

|

|

Rated/max input power

|

4.3kW/10.4kW

|

|

Rated/max running current

|

21.6A/42.1A

|

|

Electriicty heater+max input power

|

10.4kW

|

|

Electriicty heater current +max running current

|

42.1A

|

|

Drying temperure range

|

5-70C

|

|

Max circualtion wind volume

|

7000m/h

|

|

Size

|

2115.5 x 1050 x 2352mm

|

|

Noise

|

≤ 70dB

|

|

Weight

|

350kg

|

|

Minimum working pressure on suction side

|

0.05MPa

|

|

Maximum working pressure on exhaust side

|

3.0MPa

|

|

waterproof level

|

IPX0

|

|

Protection against electric shock

|

Class I

|

|

Color

|

Grey + Silver Titanium Grey

|

|

Layer distance

|

115mm

|

|

Tray

|

640*460*55mm, 36pcs

|

Features

1.Energy saving: the energy efficiency ratio is as high as 300%, 70% energy saving than electric heating drying, 30% energy saving than coal-fired drying; the operating cost is only one third of fuel oil and gas

2.Environmental protection: electricity is the only energy source, and the environment is clean and hygienic; production achieves zero emissions, efficient and sustainable development

3.Intelligent: PLC intelligent control system, high-precision temperature and humidity sensor control; one-key start, multi-scene mode, fault alarm; the whole process of drying quality is controllable, and product quality is greatly improved

4.Safety: The compressor adopts imported well-known brands, and the operation is stable; there is no danger of inflammability and explosion; water and electricity are separated, and there is no danger of leakage

1.Energy saving: the energy efficiency ratio is as high as 300%, 70% energy saving than electric heating drying, 30% energy saving than coal-fired drying; the operating cost is only one third of fuel oil and gas

2.Environmental protection: electricity is the only energy source, and the environment is clean and hygienic; production achieves zero emissions, efficient and sustainable development

3.Intelligent: PLC intelligent control system, high-precision temperature and humidity sensor control; one-key start, multi-scene mode, fault alarm; the whole process of drying quality is controllable, and product quality is greatly improved

4.Safety: The compressor adopts imported well-known brands, and the operation is stable; there is no danger of inflammability and explosion; water and electricity are separated, and there is no danger of leakage

Hot Searches