- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Supermarket

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Highbright

-

Model Number:

-

HBE

-

Depth:

-

customized

-

Weight Capacity:

-

customized

-

Width:

-

customized

-

Height:

-

customized

-

Surface treatment:

-

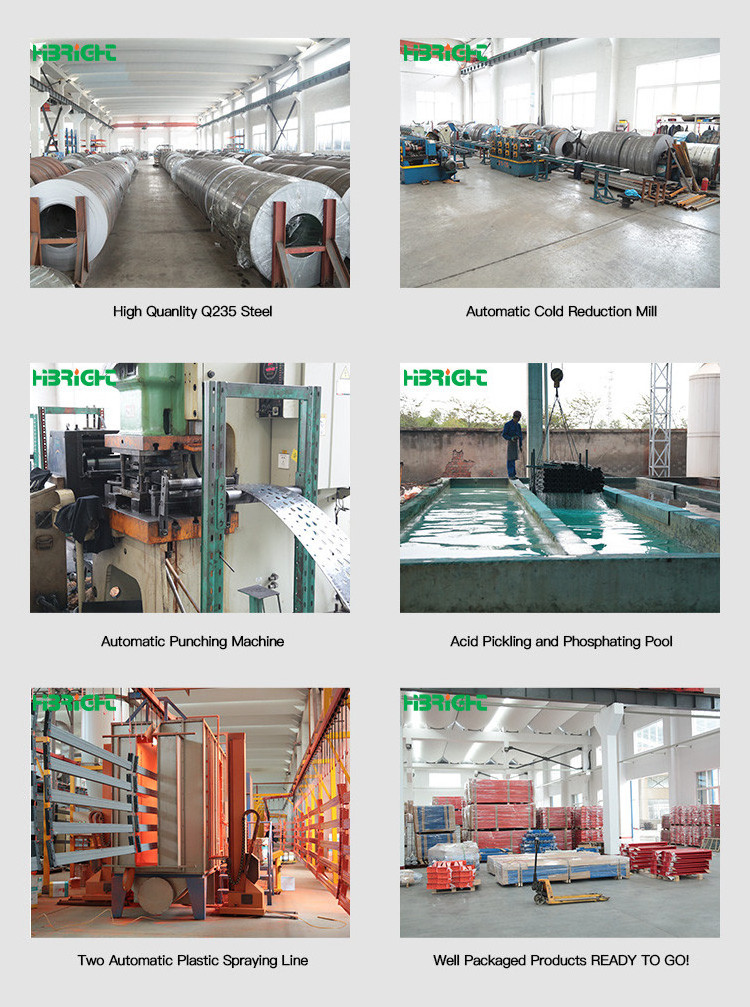

powder coating

-

Color:

-

orange and blue

-

Loading Capacity:

-

1 Ton ~ 5 Ton/layer

-

Product name:

-

drive-In pallet racking

-

Usage:

-

Warehouse

-

Finish:

-

Power Coat

Quick Details

-

Type:

-

Boltless / Rivet Shelving

-

Material:

-

Wood

-

Feature:

-

Esd Protection

-

Use:

-

Supermarket

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Highbright

-

Model Number:

-

HBE

-

Depth:

-

customized

-

Weight Capacity:

-

customized

-

Width:

-

customized

-

Height:

-

customized

-

Surface treatment:

-

powder coating

-

Color:

-

orange and blue

-

Loading Capacity:

-

1 Ton ~ 5 Ton/layer

-

Product name:

-

drive-In pallet racking

-

Usage:

-

Warehouse

-

Finish:

-

Power Coat

Drive-in/Drive-Thru Pallet Rack is ideal for stocking large quantities of relatively few product types. It can reduce overall square footage requirements by 35 percent or more compared to a standard Selective Rack configuration.

Advantages

- LIFO/FIFO (last in, first out/first in, first out) configurations

- Reduces space, cuts cost, and holds more loads with its deep lane storage

- High volume, low SKU

- Eliminates the need for multiple aisles

- Provides control over entry and exit

- Favors density as opposed to the selectivity of Selective Pallet Rack

- Designed specifically to suit your pallets and forklifts

With roll-formed Drive-In/Drive-Thru racks, products are stored several pallets deep and the lift equipment enters the structure to store or retrieve items.

A Drive-In pallet rack system uses the same entry and exit point for each storage bay, providing last in, first out (LIFO) access. A Drive-Thru pallet rack system is loaded on one side and unloaded from the other for first in, first out flow (FIFO).

A wide variety of heights and depths are available to meet any storage requirement.

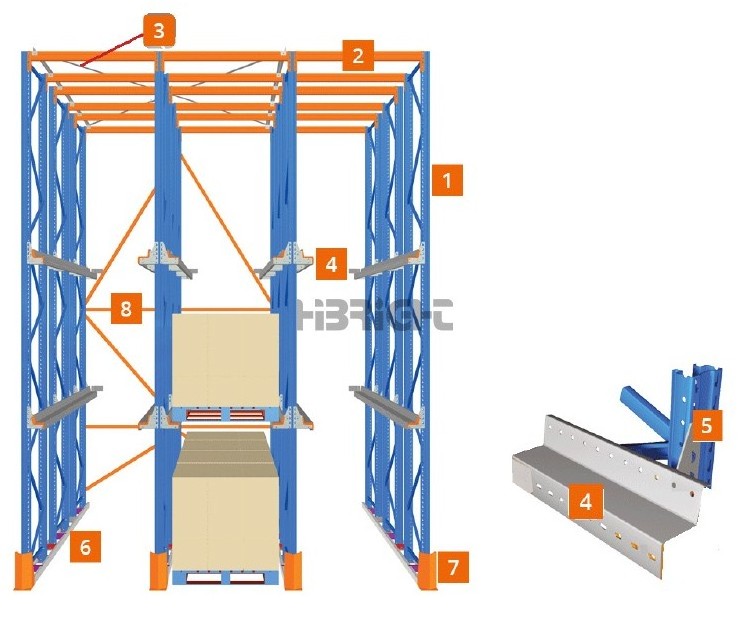

1.Upright 2.Top Beam 3.Top Bracing 4.Support Beam 5.Single/Double Support Arm 6.Guide Rail 7.Upright protecter 8.Back Bracing

Please Click the Racking System that you are interested in