- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2.5x1.9x2.6m

-

Voltage:

-

220V/380V

-

Power:

-

1000w

-

Weight (KG):

-

3000

-

Product name:

-

Industrial smokeless charcoal retort kiln for sale

-

Raw material:

-

sawdust , rice husk , wood , banboo

-

Advantage:

-

Continuous Working Environment Friendly

-

Usage:

-

Making Wood Charcoal

-

Feature:

-

Wood Charcoal Carbonization Stove Smokeless

-

Equipped With:

-

flue gas purifier

-

Capacity:

-

2-3t/24h

-

Carbonization time:

-

6-8 Hours

-

Export country:

-

Indonesia

-

After Warranty Service:

-

Spare parts

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Meida

-

Effective Volume:

-

1.5x1.5

-

Dimension(L*W*H):

-

2.5x1.9x2.6m

-

Voltage:

-

220V/380V

-

Power:

-

1000w

-

Weight (KG):

-

3000

-

Product name:

-

Industrial smokeless charcoal retort kiln for sale

-

Raw material:

-

sawdust , rice husk , wood , banboo

-

Advantage:

-

Continuous Working Environment Friendly

-

Usage:

-

Making Wood Charcoal

-

Feature:

-

Wood Charcoal Carbonization Stove Smokeless

-

Equipped With:

-

flue gas purifier

-

Capacity:

-

2-3t/24h

-

Carbonization time:

-

6-8 Hours

-

Export country:

-

Indonesia

-

After Warranty Service:

-

Spare parts

1 About accurate quote for buyer

Hi customer,

Before we give you accurate quote about charcoal machine, please tell us following details:

1 your raw materials is what ?

2 the raw materials moisture ?

3 your final product is which style charcoal ?

4 your daily capacity of the final product ? 500kg-100tons /day available .

2 About the raw materials : any biomass materials is ok

W ood log/ coconut shell / palm / peanut shell / rice husk/ straw ...... more than 30style

3 How to get charcoal from wood log directly ? only use charcoal carbonization furnace is ok

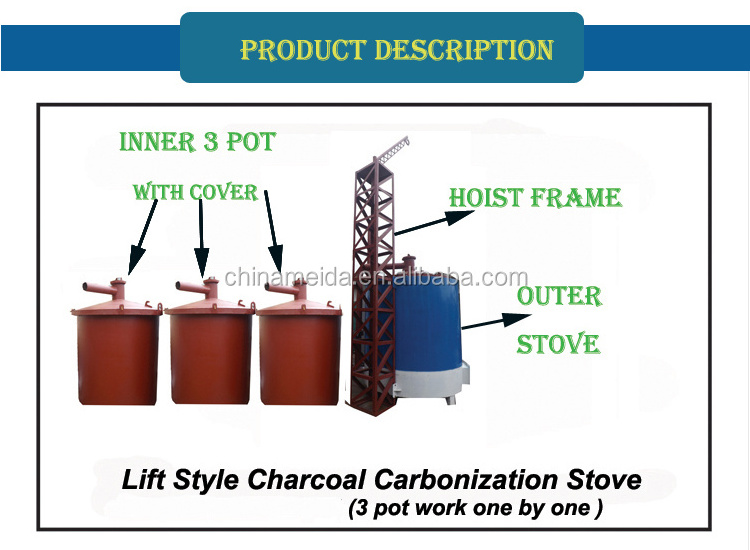

A: one machine include : 3 inner pot + 1 outer stove + 1 hoist

B: one machine each day make charcoal 2-3tons , this is final charcoal capacity

C: raw materials moisture different, the final capacity also will different

( because more moisture means carbonize time will longer )

D: for more video & photo & MANUAL, Contact us by email or whatsapp please.

4 How to make biomass briquette charcoal ? see bellow photo

A: crush raw materials into size less than 1cm

B: raw materials moisture more than 12% , need use dryer ( less than 12% no need)

C: briquette extruder machine press it to get briquette ,which with density 900-1400kg/m

D: carbonize furnace change briquette into charcoal briquette

5 How to make charcoal powder from raw materials ? See bellow photo .

1 briquette extruder

W ork Principle: this machine is used for change agriculture or forestry waste into solid fuel under

the high temperature & high pressure

|

1 raw materials : |

sawdust made from wood, peanut, coconut shell, straw , plant stalk; leaf,corn straw,wheat straw .... anything which can be burning, all can be raw materials |

|

2 raw materials moisture: |

8-12%

|

|

3 final biomass briquette density : |

900-1400kg/m

|

|

4 final briquette length : |

the machine with a automatic cutter, any length can be make

|

|

5 final briquette shape : |

hexagon or square shape

|

|

6 final briquette size : |

diameter 50mm & inside hole 15mm

|

|

7 spare parts |

spare parts include mould, heating ring, oil seal, propeller, welding rod, temperature controlled meter. |

Different Models of Biomass charcoal briquette extruder machine

|

Model |

Power |

Machine Weight |

Capacity |

Size |

|

250 |

18.5kw |

1100kg |

250-300kg/hour |

1.6*0.55*1.25meters |

|

450 |

22kw |

1400kg |

350-450kg/hour |

1.7*0.55*1.55meters |

2 carbonization furnace

|

1.The charcoal charbonize furnace suit materials |

This machine can change wood log, wood briquette, coconut shell and bamboo Palm shells etc directly into final charcoal

|

|

2.The charcoal charbonize furnace include four parts |

One whole set machine = one outer stove+ three inner stoves+ electric hoist + clean system. |

|

3 Its daily productivity of one whole sets machine |

2-3T/24hrs for dry wood with moisture less than 8% or wood briquettes. Note : different moisture of the raw materials, the daily productivity will be different & try to make sure the wood log to be similiar size, or the carbonize effect will be effected & make sure moisture no more than 50% |

|

4 Basic Work Principle- Main Features : continuous carbonization +Smoke recycle burning + Self Purifiying A- put fuel into the heating part and light it until temperature reach about 400 degree(there is a temperature indicator on the machine ) ,then put the inner pot full with wood log etc into the outer stove to be carbonization B during carbonization process, the inside charcoal briquette will produce flammable air,this air will from top to the bottom to be burning again, then it continuous to do this circulation process,so there is no pollution at all during the whole process C after one pot wood finish carbonize, then lift it out to let nother pot into the outer stove By doing this repeatly,the machine can work without stop |

|

|

5 The charcoal charbonize furnace size & weight of one whole sets machine |

Outer stove diameter 1890mm /outer stove Inner pot diameter 1500mm/1450mm/1400mm Loading Size 2.1*2.2*2.1meters. Weight 3000kg Note : 1*40GP container can hold 4 whole sets machine |

|

6 The charcoal charbonize furnace make materials |

Mn High temperature resistant plate 6-12mm according different part |

|

7 fuel consume |

20-30 kg firewood or 15 kg liquefied gas per time Only pre-heating need consume fuel, pre heating time is about 80-100minutes |

|

8 carbonization time |

Wood logs ( 8-10hours), wood briquettes (8hours), coconut shell (6hours) |

|

9 about cooling |

after carbonizing, we need to take the inside pot out, let it cool by natural way, the longer cooling time the better for charcoal quality |

Different models carbonization furnace Industrial smokeless charcoal retort kiln for sale charcoal kilncarbonization

3 continuous charcoal powder production line

Full technical details of all models

|

Model |

WTJ-3 |

WTJ-4 |

WTJ-5 |

WTJ-6 |

|

Carbonize body diameter |

800mm |

1000mm |

1200mm |

1500mm |

|

Capacity |

400-600kg/hour |

800-1000kg/hour |

1200-1500kg/hour |

2000-3000kg/ hour |

|

biomass gas furnace diameter |

1700mm |

1700mm |

1700mm |

1700mm |

|

biomass gas furnace motor |

1.1kw+3kw |

1.1kw+3kw |

1.1kw+3kw |

1.1kw+3kw |

|

Fan motor(Frequency) |

5.5kw |

5.5kw |

5.5kw |

5.5kw |

|

Continuous charcoal powder produce parts |

3kw |

3kw |

4kw |

5.5kw |

|

Cooling parts |

3kw |

3kw |

3kw |

4kw |

|

Spiral feeding |

3kw |

3kw |

3kw |

3kw |

|

Condenser |

2pcs |

2pcs |

2pcs |

2pcs |

|

Spiral separator |

2pcs |

2pcs |

2pcs |

2pcs |

|

Oil liquid separator |

2pcs |

2pcs |

2pcs |

2pcs |

|

Burner |

16pcs |

16pcs |

18pcs |

20pcs |

|

Smaller burner |

2pcs |

2pcs |

2pcs |

2pcs |

|

Carbonize work temperature |

500-800℃ |

500-800℃ |

500-800℃ |

500-800℃ |

Industrial smokeless charcoal retort kiln for sale charcoal kiln carbonization

Coal charcoal briquette making machine

charcoal ball press machine Industrial smokeless charcoal retort kiln for sale charcoal kiln carbonization

Industrial smokeless charcoal retort kiln for sale charcoal kiln carbonization

1 Simple Introduction About Meida

Gongyi City Meida Machinery

Co., Ltd

.

10 years manufacturing experience

+

6 years export experience

Product Advantage

:

high quality + never change price + 2 years warranty + engineer install abroad

2 Certificate

3 company culture

Q1: How Many raw materials can get 1 ton final charcoal ?

A1: usually 2.5-3tons raw materials to make 1ton final charcoal

Q2: What is the normal temperature for carbonizing?

A2: The temperature should around 400 °C

Q3: Wh ether you can sent engineer to do machine install ?

A3: Yes,we can sent engineer to do install & worker training