- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Henan Lanyu

-

Dimension(L*W*H):

-

1300*980*2500mm

-

Raw material:

-

Charcoal Powder

-

Name:

-

Briquette Press Machine

-

Application:

-

Fuel

-

Briquette shape:

-

Round

-

Product name:

-

Brequitte Making Machine

-

Keyword:

-

Charcoal Coal Briquetting Machine

-

Color:

-

Client's Required

-

Usage:

-

Coal Briquette Shaping Machine

-

Installation:

-

Engineers Guiding

-

Materials:

-

Steel

Quick Details

-

Weight (KG):

-

1200

-

Production Capacity:

-

50 psc/minute

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Henan Lanyu

-

Dimension(L*W*H):

-

1300*980*2500mm

-

Raw material:

-

Charcoal Powder

-

Name:

-

Briquette Press Machine

-

Application:

-

Fuel

-

Briquette shape:

-

Round

-

Product name:

-

Brequitte Making Machine

-

Keyword:

-

Charcoal Coal Briquetting Machine

-

Color:

-

Client's Required

-

Usage:

-

Coal Briquette Shaping Machine

-

Installation:

-

Engineers Guiding

-

Materials:

-

Steel

honeycomb briquette machines/biomass charcoal briquette machine/rice husk briquette machine charcoal

1.Introduce:

It is maily used to make the coal briquettes in honeycomb shapes.It has been popularly used in China for almost 80 years.Previously raw coal been processed into the coal sphere slightly larger than pingpong,and later the coal processed into one cylinder,and marked with a number of holes inside the cylinder makes it seems like honeycomb,because it can increase the surface area of coal.make the full combustion of coal, to reduce rsource waste.

(1) Raw material: All kinds of coal powder or charcoal powder.

(2) Raw material diameter: Less than 3 mm.

(3) Raw material moisture: 8-15%.

(4) Shapes of final briquettes: There are different shapes, such as round, square, flowershapes

and fan-shaped, hexagonal shapeless. Or we can custom the related moulds as your

(5)

Honeycomb diameter:

120mm; 140mm; 160mm; 180mm; 220mm or custom-made.

2. Structure:

Our honeycomb briquette machine is divided into five parts: main body, transmission part, feeding part, punching part, and transport part. And every part works together in order to provide a stable and reliable performance.

(1) Frame: consist of platen, engine base, forming the skeleton entity.

(2) Transmission part : composed of motor, belt pullry, gear, transmission shaft, etc. The motor make the gear shaft rotating through belt pulley, and through two gears pass to axis, and then by a pair of bevel gear and the axis of rotation to drive the dial, and then pass to the four panel movement.

(3) Feeding parts: consist of spindle, hopper, agitator. It will strike by axial gear mixer, beaten charcoal and load mode barrel.

(4) Punching parts: it is meanly consist of four slide, sliding beam, punch, punch holder, punch pin, activity pressure plate, end of activity mode, spring, etc.

(5) Conveying parts: consist of transmission rack, belt pulley, support, conveying belt, etc. The conveyor belt random rotation then the shaped charcoal briquettes come out of the body, the adjustable screw on the conveyor rack can adjust the tightness.

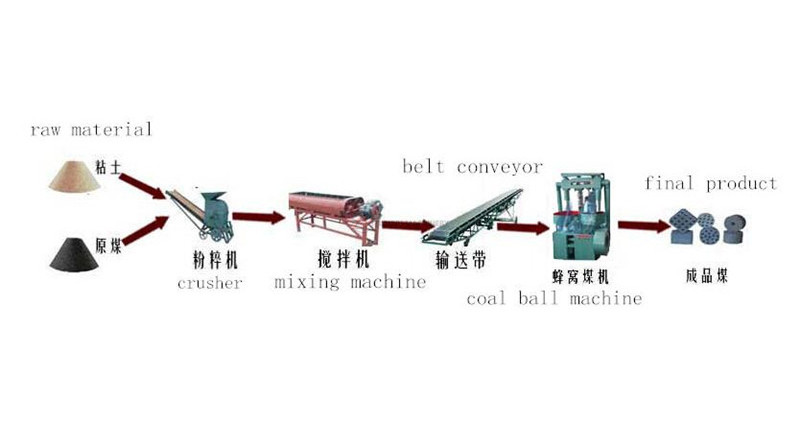

The production line

(1)Coal briquette machine production line:

Coal powder---binder mixer---crusher and mixer---conveyor belt---dosing machine---briquette machine---dryer

(2)Charcoal briquette machine production line:

Carbonization furnace---charcoal crusher---binder mixer---wheel mill---conveyor belt---dosing machine---briquette machine---box dryer.

ü Technical service s

1. Design ing production line and equipment s layout according to your specific workshop .

2. Supply ing drawing s of equipment s you ’ ve purchased .

3. Supply ing technical parameters of peripheral equipment s .

4. Offering techn ical service freely on request for adjust ing the layout in your workshop .

5. U pdating your equipments on request if necessary.

ü After-sales service s

6. During the installation and commissioning of the honeycomb coal briquette machine , we will send our technician to your site for guiding the installation and we will also offer training service for your party if requested .

7. If anything goes wrong with the honeycomb coal briquette machine because of improper handling, we’ ll take care of the maintenance if requested, and m aterial and labor costs will be charged at cost price.

8. We’ ll offer spare parts for the honeycomb coal briquette machine with favorable price and perdurable maintenance. A fter the warranty expires, only m aterial and labor costs will be charged if the equipments need to be repaired .