- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Ring-Joint Gaskets

-

MOQ:

-

5000

-

Material:

-

Metal

-

OEM:

-

OEM Service Provided

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

zhengji

-

Model Number:

-

Gasket

-

Product name:

-

Ring-Joint Gaskets

-

MOQ:

-

5000

-

Material:

-

Metal

-

OEM:

-

OEM Service Provided

Product Description

Ring-joint gaskets shall be either octagonal or ova. incross section.

Ring-joint gasket materials,shall be selected by the user based on suit-ability for the service conditions.

lt is recommended that ring-joint gaskets be of a lesser hardness than that of the mating flanges. pment or storage.

Ring-joint gasket materials,shall be selected by the user based on suit-ability for the service conditions.

lt is recommended that ring-joint gaskets be of a lesser hardness than that of the mating flanges. pment or storage.

Specification

All material shall be new material with all surface clean and free from defects, weld spatter, arc strike, rust, dirt, sand,

scale, paint or any other foreign substance.

Use of asbestos is strongly forbidden in any parts of the gaskets.

The gasket is sufficient to meet the maximum and minimum temperatures specified in each standard

Flexible graphite(FG):-200℃~+650℃

When used in oxidizing medium, the maximum service temperature is 450 ℃

Polytetrafluoroethylene(PTFE):-200℃~+200℃

Non-asbestos(NAS):-100℃~+250℃

Phlogopite(magnesium mica):≤1000℃

Vermiclite:≤1050℃

Ceramic(CER):≤1400℃

Non-metal gasket with halogen and sulfur content of less than 0.01% (weight percent), chloride and fluoride dissolved in the leaching amount is not more than 15ppm and 10ppm, Sulphate ion concentration is not more than 100ppm.

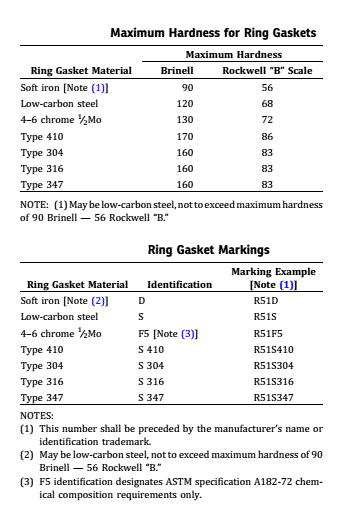

Each gasket shall be legibly marked on the exterior surface of gaskets in accordance with the applicable standard. Marking shall normally be accomplished by stencilling and/or punching. The following items shall be indicated on all gaskets.

- Nominal size

- Rating or Class

- Material specification

- Manufacturer’s name or trade mark.

- Ring number (for ring joint gaskets)

- Item code (HQBJ code)

We have established, documented, implemented and maintained a quality management system (QMS) to ensure that our products meet the specified requirements, including the requirements of ISO 9001:2000.

Tolerances in dimensions shall be according to the relevant Codes, Standards and Specifications.

We take the following measures to prevent corrosion and mechanical damage during transportation, shipment and storage:

All gaskets thoroughly cleaned of all debris, trash, weld spatter, loose mill scale, tools and foreign matter and dried in

preparation for shipment。

Gaskets shall be protected to withstand ocean/road transit and extended periods of storage at the job site for a minimum period of 18 months. Materials shall be protected to safeguard against all adverse environments, such as: humidity, moisture, rain, dust, sand, mud, salt, air, salt spray and seawater.

Rust protection for metal part of gaskets shall be performed according to the manufacturer's standard.

Austenitic stainless steel gaskets shall be protected from chloride attack during shipment or storage.

scale, paint or any other foreign substance.

Use of asbestos is strongly forbidden in any parts of the gaskets.

The gasket is sufficient to meet the maximum and minimum temperatures specified in each standard

Flexible graphite(FG):-200℃~+650℃

When used in oxidizing medium, the maximum service temperature is 450 ℃

Polytetrafluoroethylene(PTFE):-200℃~+200℃

Non-asbestos(NAS):-100℃~+250℃

Phlogopite(magnesium mica):≤1000℃

Vermiclite:≤1050℃

Ceramic(CER):≤1400℃

Non-metal gasket with halogen and sulfur content of less than 0.01% (weight percent), chloride and fluoride dissolved in the leaching amount is not more than 15ppm and 10ppm, Sulphate ion concentration is not more than 100ppm.

Each gasket shall be legibly marked on the exterior surface of gaskets in accordance with the applicable standard. Marking shall normally be accomplished by stencilling and/or punching. The following items shall be indicated on all gaskets.

- Nominal size

- Rating or Class

- Material specification

- Manufacturer’s name or trade mark.

- Ring number (for ring joint gaskets)

- Item code (HQBJ code)

We have established, documented, implemented and maintained a quality management system (QMS) to ensure that our products meet the specified requirements, including the requirements of ISO 9001:2000.

Tolerances in dimensions shall be according to the relevant Codes, Standards and Specifications.

We take the following measures to prevent corrosion and mechanical damage during transportation, shipment and storage:

All gaskets thoroughly cleaned of all debris, trash, weld spatter, loose mill scale, tools and foreign matter and dried in

preparation for shipment。

Gaskets shall be protected to withstand ocean/road transit and extended periods of storage at the job site for a minimum period of 18 months. Materials shall be protected to safeguard against all adverse environments, such as: humidity, moisture, rain, dust, sand, mud, salt, air, salt spray and seawater.

Rust protection for metal part of gaskets shall be performed according to the manufacturer's standard.

Austenitic stainless steel gaskets shall be protected from chloride attack during shipment or storage.

Hot Searches