We are the direct manufacturer and specified supplier of Briggs & Stratton, Generac, Loncin, Yamaha, Kohler, Greenworks, TTI, Senci,Ryobi and other famous customers. We are exporting the products to their plants directly.

We have about 27 years of experience in spares parts for general gasoline engines, inverter generator, battery powered equipments, such as ignition coil, AVR, voltage regulator, flywheel, inverter controller, alternator, blade motor, deck motor, driving controller, deck controller and etc.

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

YP, Yuxin

-

Model Number:

-

TJ727F.10 &TJ727F.20

-

Torque:

-

2.0N.m

-

Product Name:

-

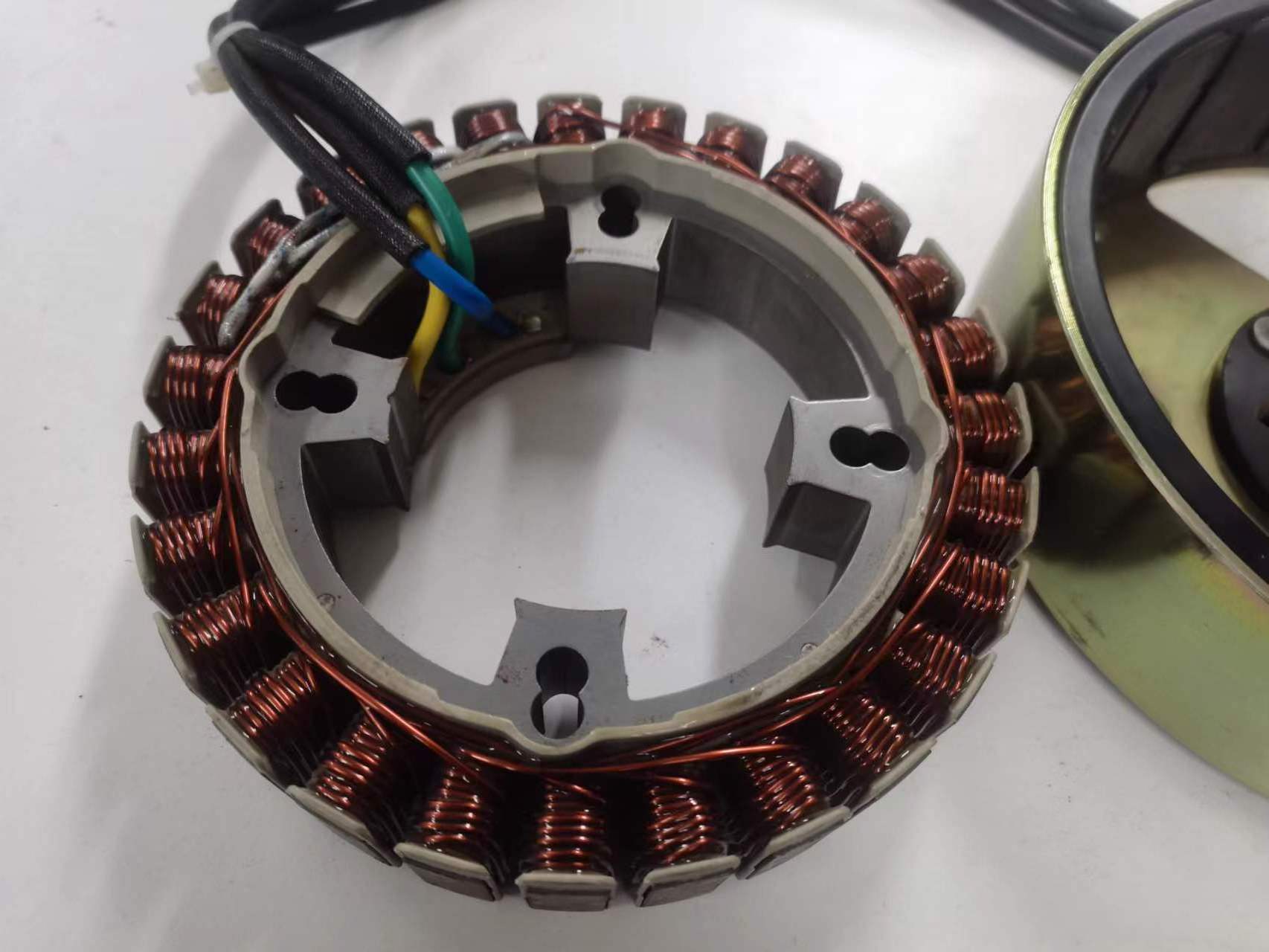

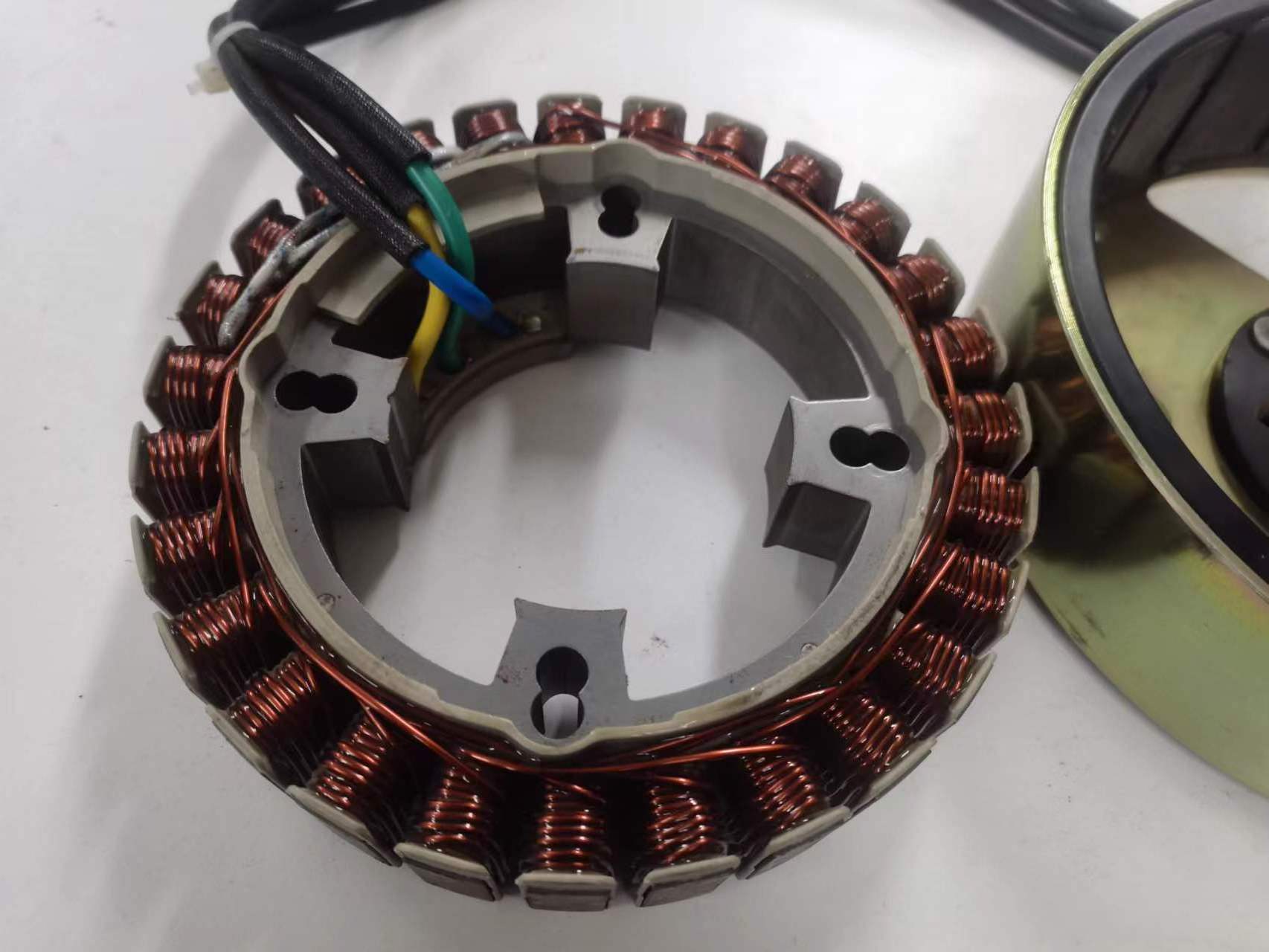

3.5KW 72V Range Extender Parts Stator & Rotor

-

Voltage:

-

72V

-

Power:

-

3.5KW

-

Application:

-

Generator Stator

-

Rated Power:

-

800W-5500KW

-

Material:

-

Pure copper coil

-

Keywords:

-

bldc motor stator

-

Noise:

-

Low Noise Level

-

Input Voltage:

-

48v-72v

Quick Details

-

Speed(RPM):

-

3000rpm

-

Continuous Current(A):

-

45A

-

Efficiency:

-

IE 4

-

Warranty:

-

1 year

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

YP, Yuxin

-

Model Number:

-

TJ727F.10 &TJ727F.20

-

Torque:

-

2.0N.m

-

Product Name:

-

3.5KW 72V Range Extender Parts Stator & Rotor

-

Voltage:

-

72V

-

Power:

-

3.5KW

-

Application:

-

Generator Stator

-

Rated Power:

-

800W-5500KW

-

Material:

-

Pure copper coil

-

Keywords:

-

bldc motor stator

-

Noise:

-

Low Noise Level

-

Input Voltage:

-

48v-72v

Product name

YP, Yuxin 48V/60V/72V 1kw-10kw generator all copper coil range extender 27 pole stator and rotor for bldc motor

Specifications

|

Item

|

Stator Description

|

Item

|

Stator Description

|

|

1

|

60V/1.1KW/4800RPM

|

15

|

60V/4KW/3600RPM

|

|

2

|

24V/2KW/4800rpm

|

16

|

72V/4KW/3600RPM

|

|

3

|

48V/2KW/4800rpm

|

17

|

60V/4KW/3600RPM

|

|

4

|

60V/2KW/4800rpm

|

18

|

72V/4.4KW/3600RPM

|

|

5

|

72V/2KW/4800rpm

|

19

|

60V/4KW/5000RPM

|

|

6

|

96V/2KW/4800rpm

|

20

|

72V/4KW/5000RPM

|

|

7

|

60V/3KW/3200RPM

|

21

|

60V/4KW/3600RPM

|

|

8

|

72V/3KW/3200RPM

|

22

|

60V/4.4KW/3600RPM

|

|

9

|

72V/3.2KW/3400RPM

|

23

|

60V/5KW/5000RPM

|

|

10

|

72V/3.6KW/3600RPM

|

24

|

300V/6KW/3000RPM

|

|

11

|

72V/3.6KW/3600RPM

|

25

|

72V/7KW/5000RPM

|

|

12

|

60V/3.6KW/3600RPM

|

26

|

72V/10KW/3000RPM

|

|

13

|

48V/3.6KW/3600RPM

|

27

|

310V/12KW/3000RPM

|

|

14

|

72V/4KW/3600RPM

|

28

|

110V/15KW/3000RPM

|

|

Item

|

Description

|

Stator Parameter

|

|

1

|

1.1KW 120V Stator

|

main winding output power: 1.1KW (4800rpm);

power supply winding:3200 to 4800rpm, voltage: 4V to 20V; ignition winding: peak voltage≥5V/650rpm; |

|

3

|

1.8KW 60V Stator

|

Ignition winding output:500rpm, UAC≥6V; 4800rpm, UAC≤99V

Stator temperature raise less than 100K |

|

4

|

2KW 230V 50HZ Stator

|

Main winding outpput power: P≥2KW (5000rpm), bulb load;

DC winding output power:5000rpm, 8A/12V±1V; Power supply winding output voltage: 3600 to 5000rpm, 12-17V |

|

5

|

2KW Stator

|

P=2 to 2.3KW 4800rpm

Insulation strength>200MΩ, leakage current of winding to ground ≤ 2mA/1800V Stator temperature raise less than 100K |

|

6

|

2.2KW 230V Stator

|

Main winding output power: 5000rpm, P≥2.4KW;

DC winding output power: 5000rpm, 8A/12V±1V; Power supply winding output voltage: 3300 to 5000rpm, 10.5 - 20V |

|

7

|

3KW Stator

|

power:3kw

speed range:2600 to 3600rpm; using temperature range:-20 to +80℃; power winding AC voltage: 2600rpm>10.5V, 3600rpm<17V; ignition winding AC voltage:300rpm>3V,3600rpm<56V |

|

8

|

4.5kW 230V Stator

|

3600rpm

Main winding output power: UAC=430±15V; P1,P2≥2.8KW(3600rpm, UDC=400V), resistive load; Ignition winding AC voltage: 3600rpm, 75±5V |

|

9

|

5KW Stator

|

Main winding output power and voltage:3600rpm, U=400V, P≥7KW;

DC power supply winding: 3600rpm, DC voltage 12V±1; Insulation strength>10MΩ, leakage current of winding to ground ≤ 2mA/1800V; Stator temperature raise less than 100℃ |

|

10

|

7KW/120V240V Stator

|

dual voltage

Main winding output voltage and power: 2600rpm,no load voltage UAC≥166V, 3600rpm, P1≥4.5KW, resistive load, P2≥4.5KW, resistive load; DC winding: 2600rpm, UAC>14.5V; 3800rpm, UAC<58V |

|

11

|

9.0kW 120V/240V Stator

|

3600rpm dual voltae

Main winding output power: speed range 2600rpm to 3600rpm, no-load voltage = 460±15V, with load UDC=400V; P1、P2≥5.2KW; Power supply winding AC voltage: 3600rpm, 35±2V, with load 60W, UDC=20-30V; DC winding AC voltage: 3600rpm, 35±2V; with load 60W, UDC=20-30V |

|

12

|

10KW 230V Stator

|

3200rpm

Main winding output voltage and power: 2600rpm, no-load voltage UAC≥300V, 3200rpm, P1≥3.5KW, resistive load, P2≥3.5KW, resistive load, P2≥3.5KW; DC winding output ower: after rectifiering, 3000rpm, no load UAC≤22V, with load I=8.3A, UDC=12±1V. |

The matched inverter controller

|

Item

|

Description

|

Inverter controller parameter

|

Item

|

Description

|

Inverter controller

parameter

|

|

|

1

|

1.6KW

|

1.6KW 50HZ 230V

|

18

|

3.5KW

|

3.5KW 60HZ 120V

|

|

|

2

|

1.6KW

|

1.6KW 60HZ 120V

|

19

|

3.5KW

|

3.5KW 50HZ 230V

|

|

|

3

|

1.6KW

|

1.6KW 50HZ/60HZ 100V

|

20

|

3.5KW

|

3.5KW 60HZ 120V

|

|

|

4

|

1.6KW

|

1.6KW 50HZ 220V

|

21

|

3.5KW

|

3.5KW 60HZ 120V

|

|

|

5

|

1.6KW

|

1.6KW 240V

|

22

|

3KW

|

3KW 50HZ 230V

|

|

|

6

|

1.8KW

|

1.8KW 60HZ 120V

|

23

|

3KW

|

3KW 50HZ 100V

|

|

|

7

|

2.3KW

|

2.3KW 60HZ 120V

|

24

|

3KW

|

3KW 50HZ 220V

|

|

|

8

|

2.3KW

|

2.3KW 50/60HZ 100V

|

25

|

3KW

|

3KW 60HZ 120V

|

|

|

9

|

2.5KW

|

2.5KW 50HZ 230V

|

26

|

5KW

|

5KW 60HZ 120V/240V

|

|

|

10

|

2.5KW

|

2.5KW 60HZ 120V

|

27

|

6KW

|

6KW 60HZ 120V/240V

|

|

|

11

|

2KW

|

2KW 60HZ 120V

|

28

|

6KW

|

6KW 50/60HZ 100V/200V

|

|

|

12

|

2KW

|

2KW 60HZ 110V

|

29

|

6KW

|

6KW 50HZ 230V

|

|

|

13

|

2KW

|

2KW 60HZ 220V

|

30

|

7KW

|

7KW 60HZ 120V/240V

|

|

|

14

|

2KW

|

2KW 60HZ 230V

|

|

|

|

|

|

15

|

2KW

|

2KW 50HZ 110V

|

|

|

|

|

|

16

|

2KW

|

2KW 60HZ 220V

|

|

|

|

|

|

17

|

2KW

|

2KW 120V

|

|

|

|

|

Products Description

The basic info of extender generator rotor: The model number is range extender generator stator rotor. The DIY supplies are electrical.

The extender generator rotor is made of high-quality metal material, with excellent performance and long service life. The rotor and stator are tightly connected, with strong magnetism, durability, and reliability. The rotor adopts imported technology, with strong magnetic absorption and high-temperature resistance, a wide range of applications. The product is used to extend the life of generators and equipment. The generator can provide excellent thermal performance for long-term use. The rotor has a special structure that can be used for more precise cutting. With a high power utilization rate, low consumption, and long service life. This multifunctional generator rotor, with high reliability and excellent performance, is an indispensable tool for generators.

Our product is fit for the series hybrid system on electric 2-wheel, 3-wheel, and 4-wheel vehicles. The vehicle takes a lithium battery or lead-acid battery as the main power. The main purpose of the range extender is to charge the battery and increase the mileage. The main output is 3~8kw, 60v/72v DC.

Product show

More Products

Manufacturing Technique

silicone steel material from famous manufacturer

Automatic high stamping for stator lamination core

Automatic injection equipments

Automatic winding for stator

100% Stator testing

Automatic machining for rotor

Inverter controller 100% testing

Aging testing of controller

Withstand voltage testing

About Us

Hot Searches