- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LIANHUA TECHNOLOGY

-

Year:

-

2024

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

4.3*2.9*3.1

-

Hollow part volume:

-

12L

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

90 mm

-

Screw Heating Power(kW):

-

21.4 kW

-

Extruder Motor Power(kW):

-

37 kW

-

Mold Platen Size(Width)(mm):

-

450 mm

-

Mold Platen Size(Height)(mm):

-

575 mm

-

Air Pressure(MPa):

-

0.6 MPa

-

Air Comsumption(m³/min):

-

0.8 m³/min

-

Die Head Heating Power(kW):

-

5.7 kW

-

Accumulator Capacity(L):

-

8 L

-

Power (kW):

-

41

-

Weight (T):

-

11

-

Hydraulic valves:

-

Yuken,Taiwan

-

Control:

-

PLC+Touch screen

-

Hydraulic pump:

-

YUKEN,Taiwan

-

Production volume:

-

12Liter

-

Working station:

-

double station

-

Guarantee time:

-

One year

-

Clamping force:

-

158KN

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

For all life

Quick Details

-

Clamping Force (kN):

-

158

-

Output (kg/h):

-

130 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LIANHUA TECHNOLOGY

-

Year:

-

2024

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

4.3*2.9*3.1

-

Hollow part volume:

-

12L

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

90 mm

-

Screw Heating Power(kW):

-

21.4 kW

-

Extruder Motor Power(kW):

-

37 kW

-

Mold Platen Size(Width)(mm):

-

450 mm

-

Mold Platen Size(Height)(mm):

-

575 mm

-

Air Pressure(MPa):

-

0.6 MPa

-

Air Comsumption(m³/min):

-

0.8 m³/min

-

Die Head Heating Power(kW):

-

5.7 kW

-

Accumulator Capacity(L):

-

8 L

-

Power (kW):

-

41

-

Weight (T):

-

11

-

Hydraulic valves:

-

Yuken,Taiwan

-

Control:

-

PLC+Touch screen

-

Hydraulic pump:

-

YUKEN,Taiwan

-

Production volume:

-

12Liter

-

Working station:

-

double station

-

Guarantee time:

-

One year

-

Clamping force:

-

158KN

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

For all life

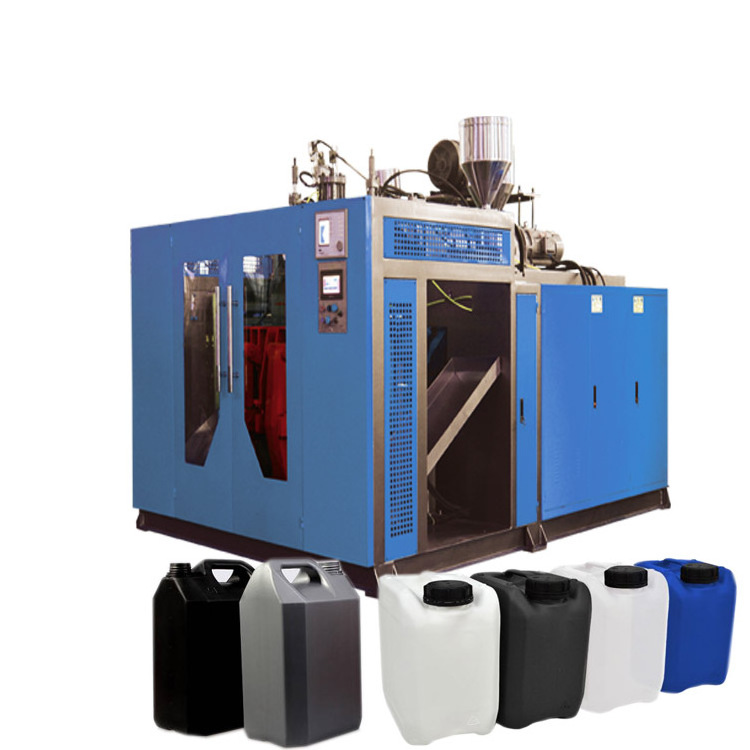

Hdpe pe plastic 1l 10liter jerry can drum blowing cooking oil bottle tank automatic extrusion blow molding machine

Extrusion

blow molding machine

model LHB90D-1

- MACHINE INTRODUCTIONS

TARGET PRODUCT

:

Jerry Can,Toy ball,Toy car wheel and eye drop bottle,etc.

MAX PRODUCT VOLUME

:

12 Liters

PLASTIC MATERIAL

:

HDPE, PP,LDPE

DELIVERY TIME

:

65 Days

GUARANTEE TIME

:

One Year

|

Machine Model

|

|

LHB90D-1 (Double

station

)

|

|

||

|

Max Product Volume

|

|

12 L

|

|

||

|

Suitable Material

|

|

PE,PP

|

|

||

|

Machine Size

|

|

4.3*2.9*3.1 m

|

|

||

|

Machine Weight

|

|

11 Tons

|

|

||

|

Voltage Suitable

|

|

Customer Specified

|

|

||

|

Screw Diameter

|

|

90 mm

|

|

||

|

L/D Ratio

|

|

24:1

|

|

||

|

Extruder Heating Power

|

|

21.4 KW

|

|

||

|

Number of Extruder Heating Zone

|

|

4 zone

|

|

||

|

Extrusion Motor Power

|

|

37 KW

|

|

||

|

Plasticizing Capacity

|

|

150 Kg/Hour

|

|

||

|

Clamping Force

|

|

158 KN

|

|

||

|

Platen Size

|

|

450*575 mm

|

|

||

|

Platen Opeing Stroke

|

|

240-620 mm

|

|

||

|

Max Mould Size

|

|

540*550 mm

|

|

||

|

Type of Die Head

|

|

Continuous

|

|

||

|

Head heating Power

|

|

9.1 KW

|

|

||

|

Number of Head Heating Zone

|

|

3 Zone

|

|

||

|

Max Die-pin Diameter

|

|

150 mm

|

|

||

|

Total Power

|

|

50 KW

|

|

||

|

Average Energy Consumption

|

|

32 KW

|

|

||

|

Air Pressure

|

|

0.6 Mpa

|

|

||

|

Air Consumption

|

|

0.8 m

3

/min

|

|

||

|

Cooling Water Needed

|

|

60 L/min

|

|

||

|

Loading Reference

|

|

20'GP

|

|

||

OPERATION CONTROL SYSTEM

CONTINUOUS DIE HEAD SYSTEM

Head mode:Special steel center-feeding continuous die head. According to the customer's production output needs,there are total four kind of heads can be selected:such as single die head, Twin die head, Tri-die head and Tetra-die head.

EXTRUSION CONTROL SYSTEM

This kind system included two pcs parts. One is Extrusion Unit(platen),another is Control system. First,Extrusion unit included 10 pcs

parts:screw,barrel,wheel,

extrusion motor,gearbox

(Speed

reducer),heater bands,cooling fans,belt,guard rail and hopper.

Specially, for the guard rail color you can select:yellow,white,black,etc as you want;For the hopper color,you can choose green,blue,white,etc as you need;For the hopper material,you can select:common steel then spray painting or stainless steel as you want. Last,for the control system,we adopts A.C.Inverter to control the plasticizing capacity,my standard brand is Inovance from China or you can choose other brand like Yaskawa from Japan,Parker brand from UK,Emerson brand from America,etc as you want.If you make the choice,

Click here!

ENERGY SAVE SYSTEM

This kind machine fixed hydraulic servo energy saving system,low power consumption,low noise,fast response,working more stable.(it

can save energy power about 10 kilo/watt one hour) So now if you make choice,

Click here!

ELECTRICAL CONTROL SYSTEM

Japan Mitsubishi PLC(for Program)+ Japan Mitsubishi automatic temperature control module.We can supply various kind of installation solution.In general,big machine fixed separate box out from the machine,small machine fixed on the machine.We supply new style stainless steel chain and lock the box.There are various color can be selected:blue,green,white,etc. According to your requirement,we can fixed the Ampere meter outside of the door or heating zone separate control by switch as you want,if like that we can fixed the sensor inside.We adopts spray painting and baking varnish on the electric box,make it more beautiful and long working life. Please note this detail:we adopts the power plug adapts connection.It works more convenient than traditional

terminal connection. So now if you make the choice,

Click here!

CLAMPING CONTROL SYSTEM

We adopts standard single station fixed clamping system.Four tie-bar big cylinder center-lock the mold.The mold platen fixed on linear guide rails & ball bearing sliders to increase action smoothness and position precision.The end positions & slow speed positions are controlled by proximity

switches(standard) or electric transducer as you need.

Meanwhile,we can supply double station clamping unit for special order

.Because the double station machine products output will be up 15%~20% than the single one.

Please note that we fixed the hydraulic motor in here in order to

lift&down the extrusion system

.

So now if you make the choice,

Click here!

TURNKEY SOLUTION

We can supply the Turnkey solution according to your requirements.So if you are interested in it,please Click here !

1. Reply the email and take action in 2 hours;

2. 100% Quality inspection before the shipment;

3. Trainning clients operator for free in seller`s factory or the user's factory;

4. Engineer overseas is available;

5. Customized design as requirements;

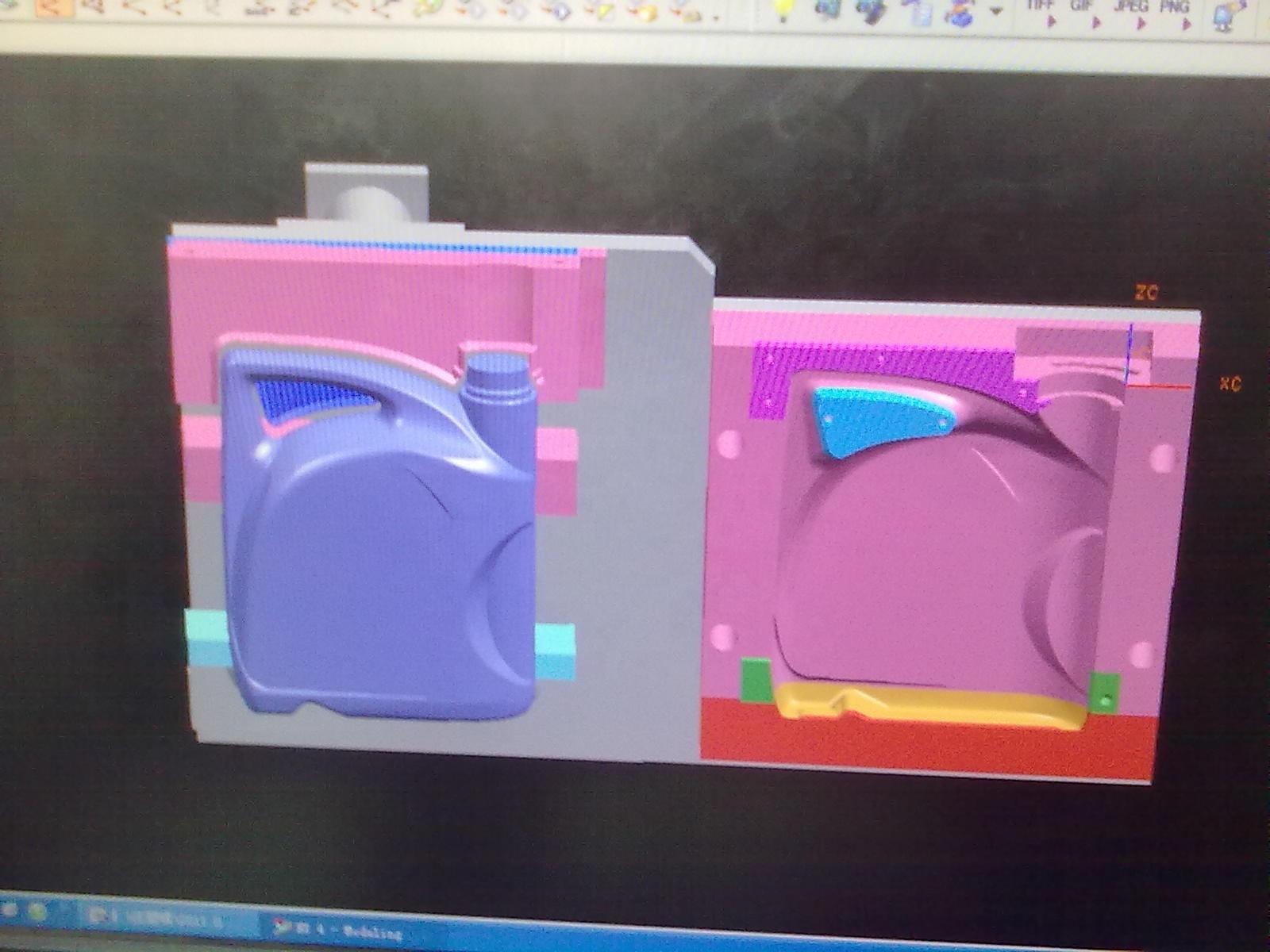

Q1: How I Can Get A Correct And Economical Project Quotation From You?

A1:

The more detailed product information you could show us, the more correct project solution plan we could make for you. Usually

we need your target products' photos or design, dimension and weight are very helpful for us to calculate production capacity

correctly. If you want some changes or optimization based on the sample, we also can help you to make design update according to

blow-molding technics and our experience. Your requirements are welcome, further communication helps both you and us to know your

production plan mutually, think of the solution together and achieve your goal successfully.

Q2: Are Your Price Is the Lowest In This Field? If Not, Why I Buy From You?

A2:

The mutual development of you and us is based on products' quality price rate and working efficiency. We don't supply the

lowest price machines, but we provide the highest quality price rated machines. Quality to us is seen as professional

consultation,economical production plan, reasonable design, precision process, accurate assembly, strict quality control, serious

commissioning, experienced installation, patient training, responsible service and selfless sharing. We try to achieve every step

best and effectively to get higher quality price rate.

Q3: How You Can Insure My Machines' Quality & Performance?

A3:

Our quality control starts from the beginning, rather than waiting till the machine is done. Under more than 30 years

extrusion blow molding machines' development, details updating, practical working, customers' feedback and our improvement, our

machines' design and configuration have been mature enough. In each production link and step the quality control is executing to

related with our employees' assessment and income level. After your machine is finished, we will make 2-3 times commissioning and

test run to make sure working performance is stable, rather than leaving the potential problems to our customers. Before

delivery,we will check everything again.