- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

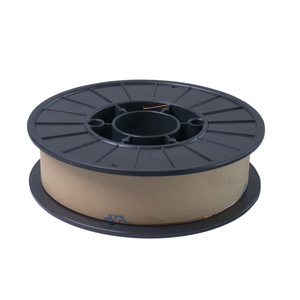

Ca30Si60

-

Shape:

-

Wire

-

Material:

-

CaSi

-

Chemical Composition:

-

Ca, Si, Fe, Al

-

Product name:

-

Calcium silicon cored wire, other alloy cored wire

-

Purity:

-

Ca30Si60

-

Color:

-

Silver Gray

-

Usage:

-

Steel Making

-

Certificate:

-

ISO9001:2015

-

MOQ:

-

20 Tons

-

Appearance:

-

Smooth

-

Package:

-

Packing with plastic bag, steel cage, and on the wooden pallet

-

Delivery time:

-

7-15 Days

-

Diameter:

-

13mm

Quick Details

-

Application:

-

Steelmaking

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZHENXIN

-

Model Number:

-

Ca30Si60

-

Shape:

-

Wire

-

Material:

-

CaSi

-

Chemical Composition:

-

Ca, Si, Fe, Al

-

Product name:

-

Calcium silicon cored wire, other alloy cored wire

-

Purity:

-

Ca30Si60

-

Color:

-

Silver Gray

-

Usage:

-

Steel Making

-

Certificate:

-

ISO9001:2015

-

MOQ:

-

20 Tons

-

Appearance:

-

Smooth

-

Package:

-

Packing with plastic bag, steel cage, and on the wooden pallet

-

Delivery time:

-

7-15 Days

-

Diameter:

-

13mm

Product Description

Calcium metal for sale.

Calcium is a chemical element with a symbol of Ca and an atomic number of 20. As an alkaline earth metal, calcium is very active will form a black coating of nitride and oxide when exposed to the air.

Calcium metal or metallic calcium is a silver-white metal. It is mainly used as a deoxidizing, decarburizing, and desulfurizing agent in alloy steel and special steel production. It is also used as a reducing agent in high-purity rare earth metal processes.

Calcium metal or metallic calcium is a silver-white metal. It is mainly used as a deoxidizing, decarburizing, and desulfurizing agent in alloy steel and special steel production. It is also used as a reducing agent in high-purity rare earth metal processes.

Specification

|

Alloy Cored Wire Type

|

Diameter

|

Filling rate

|

Specification

|

|

CaSi Cored Wire

|

9mm/13mm/16mm

|

120/225/330

|

Ca:30%min Si:55%min Al:1.5%max

S:0.06%max C:1.0%max Fe:4%max P:0.05%max |

|

CaFe Cored Wire

|

9mm/13mm/16mm

|

140/260/360

|

Ca:30%min Fe:68%min Al:0.8%max

|

|

C Cored Wire

|

9mm/13mm/16mm

|

55/140/210

|

C:98.5%min Ash:0.45%max V:0.4%max

S:0.5%max H2O:0.3%max P:0.2%max |

|

Pure Ca Cored Wire

|

9mm/13mm

|

58/155

|

Ca:98.5%min Mg:0.5%max Al:0.5%max

|

|

Solid Ca Cored Wire

|

9mm/10mm

|

9mm/10mm

|

Ca:98.5%min Mg:0.5%max Al:0.5%max

|

|

FeS Cored Wire

|

9mm/13mm

|

220/370

|

S:48%min Pb:0.1%max Zn:0.1%max

As:0.1%max Fe:43%-45% Cu:0.05%max Moisture:0.5%max SiO2:2.5%max |

|

CaAlFe Cored Wire

|

9mm/13mm

|

130/230

|

Ca:40% Fe:30% Al:30%

|

|

Pure Mg Cored Wire

|

9mm/13mm

|

80/170

|

Mg:99%min

|

|

SiBaCa Cored Wire

|

9mm/13mm

|

110/260

|

Si:40%-50% Ba:10%-20% Ca:20%-30%

|

|

FeSi Cored Wire

|

9mm/13mm

|

150/350

|

Si:75%min Fe:Balance

|

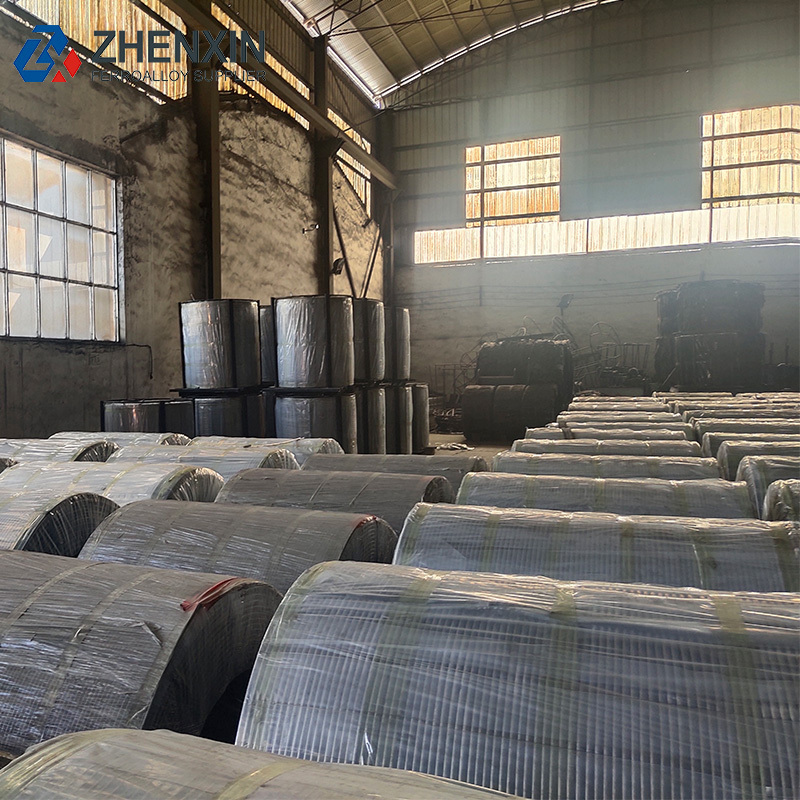

Packing & Delivery

Packing: Vertical coils in steel cages on wooden ( or steel) pallets, plastic shrink wrapped, or as customer requirement.

Our Advantages

Why chose ZX coredd wire?

* ZX alloy cored wire has the advantages of uniform powder feeding, regular assembly size, and low wire breakage rate;

* The ZX alloy cored wire is firmly wrapped and sewed, without powder leakage, slotting, virtual package, empty package, the

surface of the wire is smooth, and the weight deviation of the powder core is generally5g/m;

* The alloy cored wire is divided into two types: internal drawing type and external release type. The mechanical equipment

required for feeding the wire is simple and reliable, and it occupies a small area. In particular, the internally drawn cored

wire is more suitable for use in narrow venues;

* The use of alloy cored wire can play the role of pure molten steel and partially change the nature and shape of inclusions,

which can improve the quality of molten steel and improve the casting state;

* ZX alloy cored wire is beneficial to adjust and control the content of easily oxidizable elements and trace elements, greatly

increase the alloy yield, reduce the smelting cost, and accurately control the composition.

* The ZX alloy cored wire is firmly wrapped and sewed, without powder leakage, slotting, virtual package, empty package, the

surface of the wire is smooth, and the weight deviation of the powder core is generally5g/m;

* The alloy cored wire is divided into two types: internal drawing type and external release type. The mechanical equipment

required for feeding the wire is simple and reliable, and it occupies a small area. In particular, the internally drawn cored

wire is more suitable for use in narrow venues;

* The use of alloy cored wire can play the role of pure molten steel and partially change the nature and shape of inclusions,

which can improve the quality of molten steel and improve the casting state;

* ZX alloy cored wire is beneficial to adjust and control the content of easily oxidizable elements and trace elements, greatly

increase the alloy yield, reduce the smelting cost, and accurately control the composition.

Hot Searches