1.

Loading Capacity:

Max 3000KG

2.

Suitable Coil Core:

508mm

3.

Suitable Coil Width:

500mm

4.

Frame Structure:

Square Pipe & C-Beam

5.

Shaft Diameter:

70mm

6.

Bearing Type:

6210

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380V/50HZ

-

Weight:

-

6500 kg

-

Marketing Type:

-

New Product

-

Raw material:

-

Steel GI PPGI SS

-

Cutting blade material:

-

Gcr12mov

-

Roller material:

-

45#steel after quenched and chromed

-

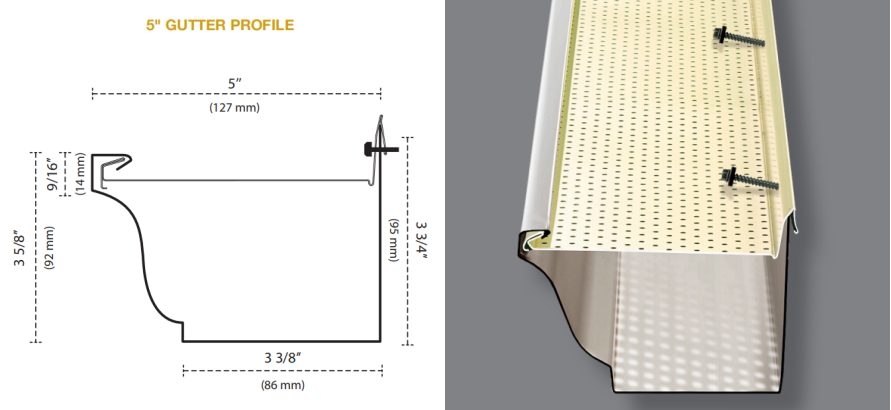

Application:

-

make for rain gutter

-

Roller Stations:

-

18 forming units

-

Control system:

-

PLC

-

Advantage:

-

Easy installation and full automatic easy operation

-

Control box language:

-

English can be customized

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

After Warranty Service:

-

Field maintenance and repair service

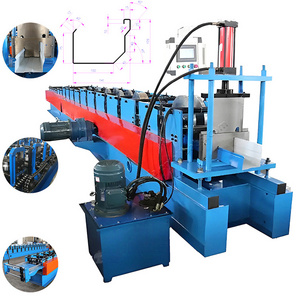

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

10-12m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380V/50HZ

-

Weight:

-

6500 kg

-

Marketing Type:

-

New Product

-

Raw material:

-

Steel GI PPGI SS

-

Cutting blade material:

-

Gcr12mov

-

Roller material:

-

45#steel after quenched and chromed

-

Application:

-

make for rain gutter

-

Roller Stations:

-

18 forming units

-

Control system:

-

PLC

-

Advantage:

-

Easy installation and full automatic easy operation

-

Control box language:

-

English can be customized

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

After Warranty Service:

-

Field maintenance and repair service

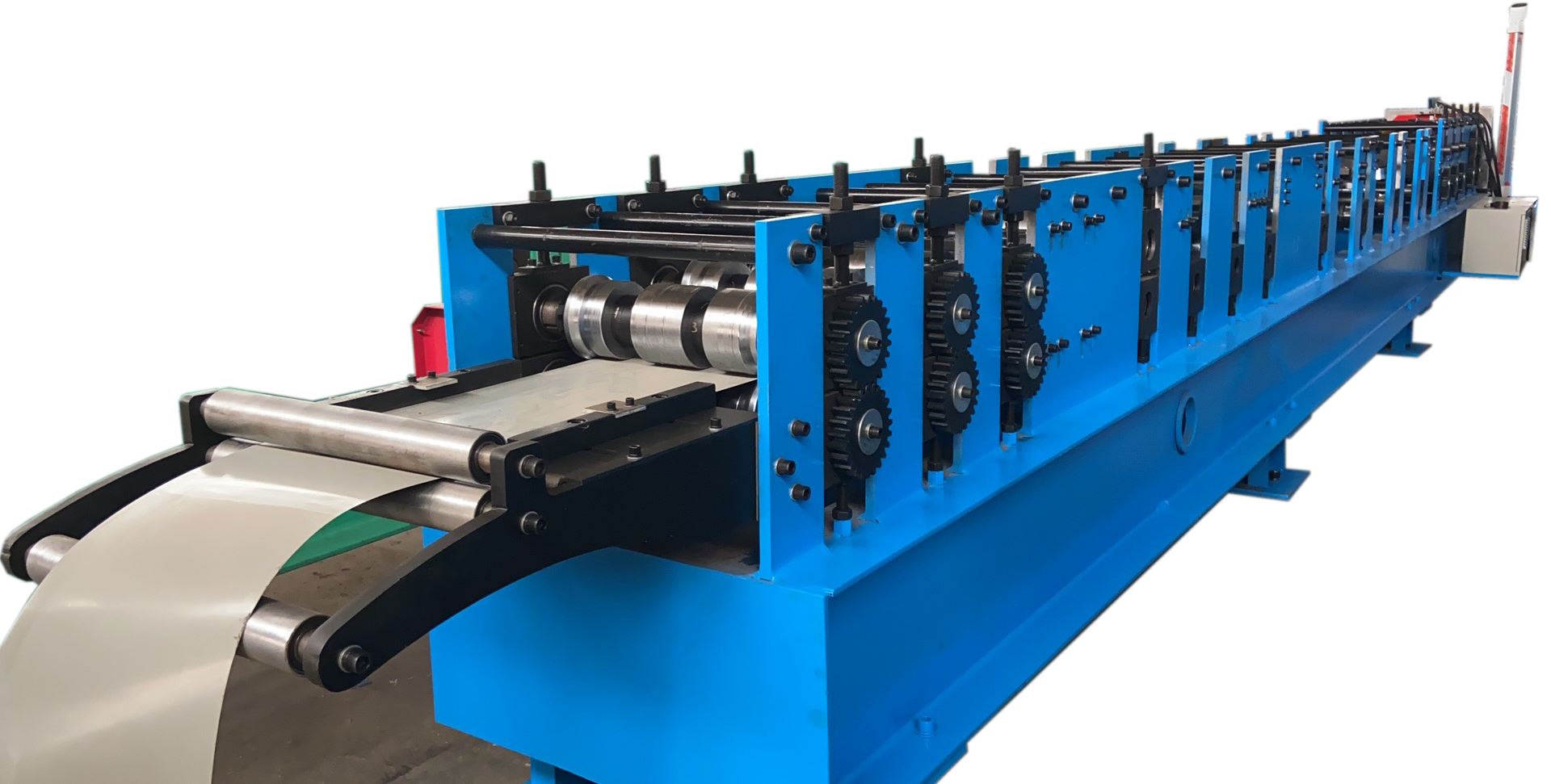

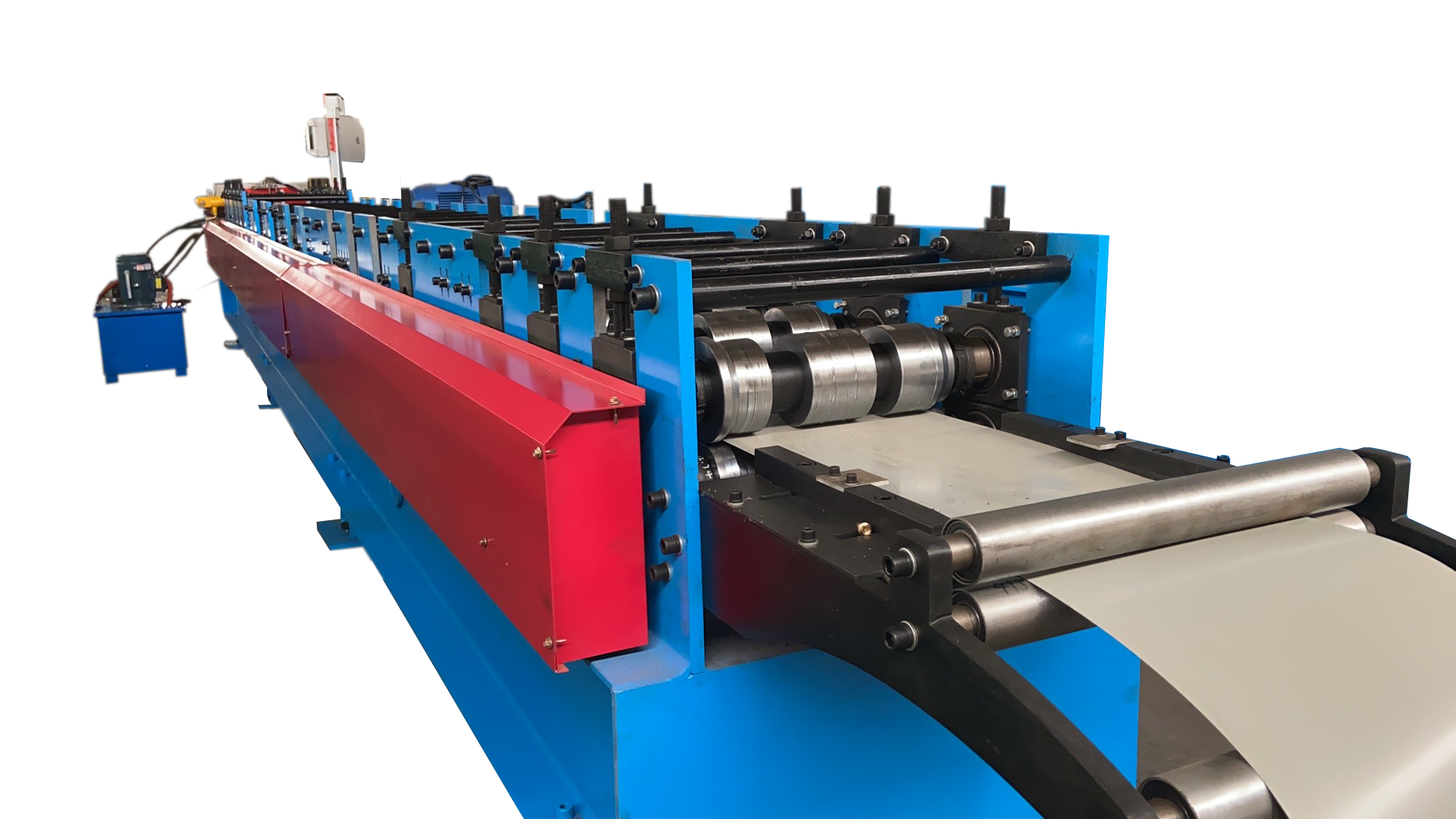

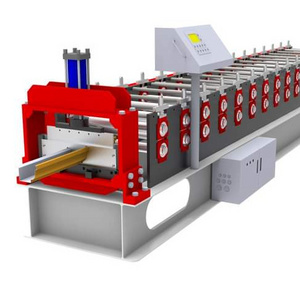

ZTRFM Full Automatic 5 Inch Rain Gutters Rolling Forming Machine

|

ZTRFM Full Automatic 5 Inch Rain Gutters Rolling Forming Machine

|

|

|

|

Base Frame Structure

|

350 H-beam welded

|

|

|

Sidewall thickness

|

16mm A3 Carbon Steel seamless welded with base frame

|

|

|

Roller Stations

|

18 forming units

|

|

|

Connect Bar

|

Diameter 25mm galvanized steel rod

|

|

|

Roller Shaft(Solid)

|

70mm-0.01~-0.03 with Key-way

|

|

|

Shaft Material(Hard)

|

High grade 45# steel,lathe then polishing smoothly

|

|

|

Roller Material(Hard)

|

High grade 45# steel,CNC lathe then chromed plated 0.05mm

|

|

|

Screw and bolts

|

Common 8.8 standard

|

|

|

Transmission method

|

0.6 inch

|

|

|

Driving motor

|

4.0KW

|

|

|

Motor reducer

|

4.0KW

|

|

|

Forming speed

|

10-12m/min

|

|

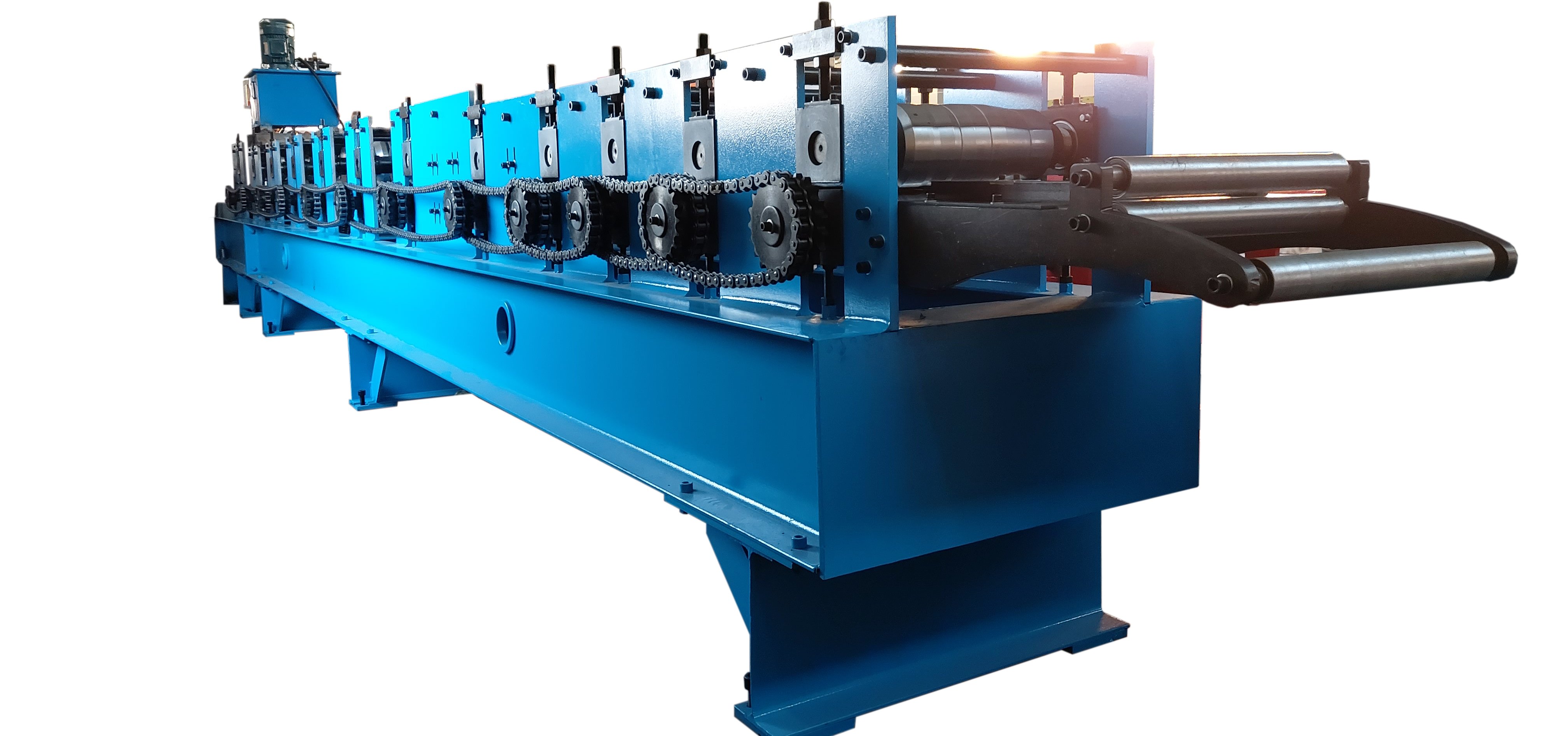

Manual Decoiler

Feeding Part

Usage:

Put the raw material (steel plate) through the beach to manufacture and process, it can

guarantee that the products are neat, parallel and everything is uniformity.

Please refer to the equipment regulation to know the function of locate board.

Main Roll Forming System

1.

Base Frame Structure:

350 H-beam welded

2.

Roller Stations:

18 forming units

3. Connect Bar: Diameter 25mm galvanized steel rod

4. Roller Shaft(Solid): 70mm-0.01~-0.03 with Key-way

5. Shaft Material(Hard): High grade 45# steel, lathe then polishing smoothly

3. Connect Bar: Diameter 25mm galvanized steel rod

4. Roller Shaft(Solid): 70mm-0.01~-0.03 with Key-way

5. Shaft Material(Hard): High grade 45# steel, lathe then polishing smoothly

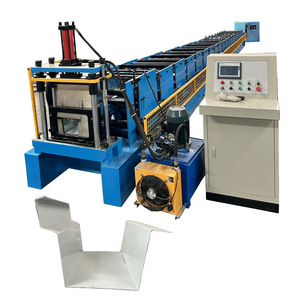

Hydraulic cutting Device

1.

Frame Structure:

A3 Carbon Steel Plates welded & Guide Pillar

2. Working Method: Stop to post , and post to cut

3. Cutting: Inside sealing Cu Spacer, whole life no maintain,only inject oil

4. Cylinder Quantity: 1 Unit

5. Cutting Blade: Cr12Mov

6. Cutting Tolerance: 10M±1.5mm

2. Working Method: Stop to post , and post to cut

3. Cutting: Inside sealing Cu Spacer, whole life no maintain,only inject oil

4. Cylinder Quantity: 1 Unit

5. Cutting Blade: Cr12Mov

6. Cutting Tolerance: 10M±1.5mm

Manual receiving table

1.

Production Length:

3000MM

2. Production Width: 500mm

3. Control Method: Manual receiving

4. Frame Structure: Square pipe & screws, roller moving

2. Production Width: 500mm

3. Control Method: Manual receiving

4. Frame Structure: Square pipe & screws, roller moving

CE(No.OP180719.CZIDC95)

ISO 9001(No:ZL92090220234630)

Why Choose Us

Hot Searches