- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

4Kw

-

Weight (KG):

-

1500

-

Name:

-

industry pipe sawdust dryer

-

Capacity:

-

400-600Kg/h

-

The moisture of raw material:

-

20-40%

-

Motor power:

-

4Kw

-

End material's moisture:

-

8-12%

-

Installation:

-

Engineer's Guidance

-

Advantage:

-

High Capacity

-

Heating method:

-

wood,gas,oil etc

-

Weight:

-

1.5t

Quick Details

-

Type:

-

Rotary Drying Equipment

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mingyang

-

Voltage:

-

380V

-

Power:

-

4Kw

-

Weight (KG):

-

1500

-

Name:

-

industry pipe sawdust dryer

-

Capacity:

-

400-600Kg/h

-

The moisture of raw material:

-

20-40%

-

Motor power:

-

4Kw

-

End material's moisture:

-

8-12%

-

Installation:

-

Engineer's Guidance

-

Advantage:

-

High Capacity

-

Heating method:

-

wood,gas,oil etc

-

Weight:

-

1.5t

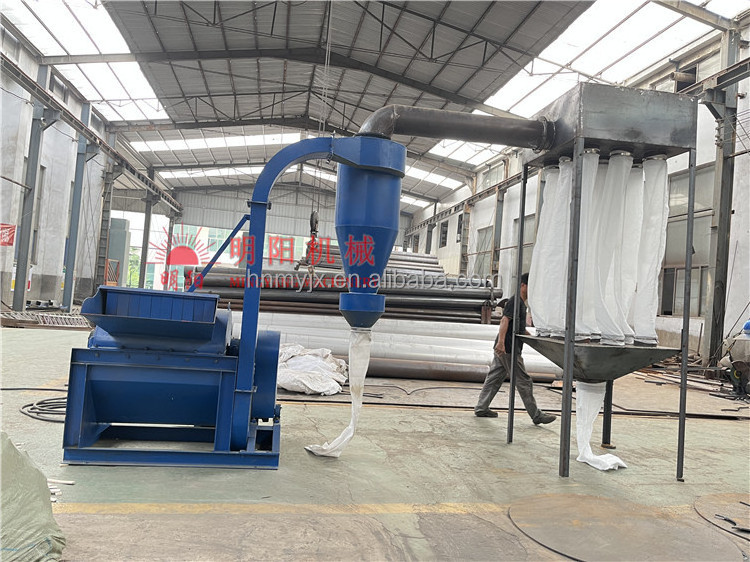

The whole line of making wood briquette charcoal:

2.Dry the material by machine or dried it in the sun , till the moisture is less than 12%.

3.Put the material into feed let of briquette machine.

4.Produce the briquette stick from biomass material without any additive.

5.Carbonized the briquette stick.

1.Wood crusher

2.Swdust dryer

3.Briquette machine

4.Carbonization stove

Product Application:

Hot airflow type:

2. Diameter of raw materials: >3mm & < 5mm;

3. Temperature of Hot Air: 180-250 ;

4. Working principle: The stoves (boilers) generate hot air, then through the fan to dry the materials;

5. This wood dryer reduces the moisture to 8-12% with the advantages of lower cost consumption and high efficiency;

6. The wood dryer is equipped with one fuel boiler, inlet, steel pipe, exhaust blower (fan), cyclone.Wet materials are input into the hopper. The fuel boiler generates hot air which mixes with wet materials and then is sucked into the pipes by the exhaust blower (fan) quickly. And then hot air is flowing and going though the curving pipes and buffer (drying chamber) of dryer, thus wet materials is finished to dry, and the dried materials are expelled out by the exhaust blower (fan).

|

Model

|

Power(kw)

|

Capacity(kg/h)

|

Weight(kg)

|

Moisture content

|

|

HJ-4

|

4

|

300-400

|

1000

|

20-40% to 8-12%

|

|

HJ-6

|

4

|

400-600

|

1500

|

20-40% to 8-12%

|

|

HJ-8

|

11

|

700-800

|

1800

|

20-40% to 8-12%

|

|

HJ-10

|

15+0.75

|

800-1000

|

2500

|

20-40% to 8-12%

|

Gongyi Xiaoyi Mingyang Machinery plant is located in Zhengzhou.Henan province.

Our machinery plant is specialize in WOOD BRIQUETTE MACHINE 38 years.

There have production line of makingwood charcoal briquette(including crusher , dryer , wood briquette machine, carbonization stove) ,

production line of making wood pellet (including crusher, dryer , wood pellets machine , dust separation plant and packaging machine)

production line of making coal ball briquette(includingvertical crusher, mixing machine, coal briquette pressing machine and dryer machine for coal briquette)

and other equipment such as screw conveyor, belt conveyor, scrap conveyor , sawdust carbonization stove, floating fish feed machine and so on.

Our machines have the best quality and we have got many certification such as CE, ISO, BV.

ave got many certification such as CE, ISO, BV.

If you have interest on our machine or have questions on our machine, please don't hesitate to contact us.