- Product Details

- {{item.text}}

Quick Details

-

Power:

-

55KW

-

Dimension(L*W*H):

-

According to the Requirement

-

Weight:

-

29000 kg

-

Product name:

-

HZS25/35/50/75 HZS60/90/120/180/240/270

-

Model:

-

HZS 25m3-270m3

-

Productivity:

-

25-270m3/h

-

Mixer:

-

JS500/1000/1500/3000/4500

-

Aggregate:

-

≤80mm

-

Control system:

-

Full-automatic

-

Total power of the plant:

-

55-383KW

-

Color:

-

Customers Defined Color

-

After Warranty Service:

-

Video Technical Support/On-site Support

-

Keyword:

-

concrete batching plant

Quick Details

-

Machine Type:

-

Production line

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GLOBAL ZEYU

-

Power:

-

55KW

-

Dimension(L*W*H):

-

According to the Requirement

-

Weight:

-

29000 kg

-

Product name:

-

HZS25/35/50/75 HZS60/90/120/180/240/270

-

Model:

-

HZS 25m3-270m3

-

Productivity:

-

25-270m3/h

-

Mixer:

-

JS500/1000/1500/3000/4500

-

Aggregate:

-

≤80mm

-

Control system:

-

Full-automatic

-

Total power of the plant:

-

55-383KW

-

Color:

-

Customers Defined Color

-

After Warranty Service:

-

Video Technical Support/On-site Support

-

Keyword:

-

concrete batching plant

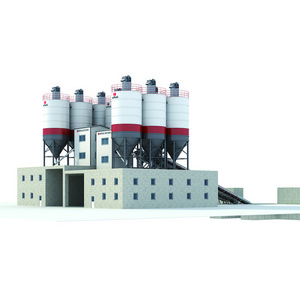

Product Overview

·Lifting Hopper For Aggretage Loading

·Three/Four Bins Batching MachineCumulative/Single aggregate Measurement

·25,40,50,75Cubic Meters/Hour Production Capacity

·Belt Conveyor For Aggreate Loading

·Pre-Storage Bin Included

·Four/Three Bins Batching Machine

·Single/Cumulative Aggregate Measurement

·60,90,120,180,240,270Cubic Meters/Hour Production Capacity

·Complete Production Line, Easy Installation

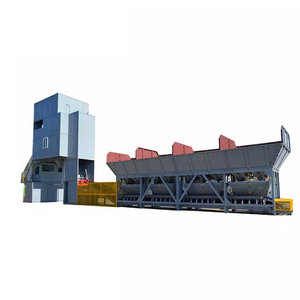

·Highly Integrated, Removable, Cover A Small Area

·35, 50/60, 75/90, 120 Cubic Meters/Hour Production Capacity

·Fully enclosed main building, effectively preventing noise leakage during mixing with belt conveyors, feeders, and mixers

·Fully enclosed conveyor belt conveyor, effectively preventing dust leakage

·Equipped with dust removal system

·25、35、 50、60,、75、90,、120、180、240、270、 Cubic Meters/Hour Production Capacity

Product Details

·High Efficiency

- combined with German Liebherr, Italy Sigoma technology

·Durable

- Q345 material original plate

·Stable Quality

- shell all tooling production

·Precision

- automatic CNC cutting machine cutting

·Easy Replacement And Maintenance/Stable Operation

- separate seal and bearing

Aggregate Storage Bin

Aggregate batching machine includes cumulative / single measurement batching way which mainly for sand , stone

Aggregate Pre-storage Bin

Aggregate storage bin could have aggregate material ready for once mixing , in order to improve the production efficiency

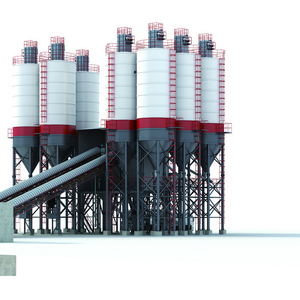

Powder Silo

Powder silo mostly for cement , flyash and mineral powder material

Additive Storage Bin

Additive storage bin is use for additive material storage water common comes from water well or lake

Flat Belt Conveyor

Use for aggregate material transmission after batching and weighing

Lifting Hopper

Use for loading the aggregate material into mixing system

Inclined Belt Conveyor

Use for loading the aggregate material into mixing system

Conveying System

Use for transmission of powder material from storage into mixing system

Single Measurement

There is a measuring hopper below each type of aggregate bin, and three tension sensors are hung through suspension bolts for weighing

Cumulative Measurement

There is only one measuring hopper under the aggregate bin, and four tension sensors are hung through suspension bolts for weighing

Single Measurement

The powder is transported to the powder measuring hopper through a screw conveyor and weighed by sensors on the measuring hopper

Water Metering Bucket

Directly transport water to the water metering hopper through a submersible pump

Additive Metering Hopper

Transport water to the metering hopper through sewage pump

Control Room

Electric Control Cabinet

Operation Console

With the function of ratio storage, automatic compensation of drop, compensation of sand and stone moisture content (sand and stone moisture content tester needs to be ordered separately), it can accurately and conveniently input, adjust and modify the set value and formula number of each material

Product Parameters

|

|

HZS25

|

HZS35

|

HZS50

|

HZS75

|

|

Theoretical Productivity

|

25m3/h

|

35m3/h

|

50m3/h

|

75 m3/h

|

|

Model Of Mixer

|

JS500

|

JS750

|

JS1000

|

JS1500

|

|

Mixing Motor Power

|

18.5kw

|

30kw

|

2x18.5kw

|

2x30kw

|

|

Cycle Period

|

60s

|

60s

|

60s

|

60s

|

|

Volume Of Mixer

|

500l

|

7501

|

10001

|

15001

|

|

Aggregate

|

≤80mm

|

≤80mm

|

≤80mm

|

≤80mm

|

|

Volume Of Cement Silo

|

2x100t

|

2x100t

|

3x100t

|

3x100t

|

|

Capacity Of Batching Plant

|

8001

|

12001

|

16001

|

24001

|

|

Volume Of Aggregate Bins

|

3x4m3

|

3x4m3

|

3x6m3

|

3x6m3

|

|

Quantity of aggregate

|

3

|

3

|

3

|

3

|

|

Productivity Of Aggregate Beltconveyor

|

100t/h

|

150t/h

|

200t/h

|

250t/h

|

|

Max. Productivity Of Screw Conveyor

|

40 t/h

|

40 t/h

|

80 t/h

|

80 t/h

|

|

Unloading Height

|

1.6m

|

3.8m

|

4.0m

|

4.0m

|

|

Total Power Of The Plant

|

55kw

|

75kw

|

105kw

|

150kw

|

|

Measuring Range And Precision Of Aggregate

|

(1000-2000)±2% kg

|

(1000-3000)±2% kg

|

1000-4000)±2% kg

|

(1000-4000)±2% kg

|

|

Measuring Range And Precision Of Cement

|

(100-300)±1% kg

|

(150-500)±1% kg

|

(200-600)±1% kg

|

(200-800)±1% kg

|

|

Measuring Range And Precision Of Coal Ash

|

|

|

(100-300)±1% kg

|

(100-400)±1% kg

|

|

Measuring Range And Precision Of Water

|

(100-200)±1% kg

|

100-300)±1% kg

|

(100-450)±1% kg

|

(100-600)±1% kg

|

|

Measuring Range And Precision Of Admixture

|

(0-20)±1% kg

|

(0-20)±1% kg

|

(10-50)±1% kg

|

(10-50)±1% kg

|

|

|

HZS60

|

HZS90

|

HZS120

|

HZS180

|

HZS240

|

HZS270

|

|

Theoretical Productivity

|

60 m3/h

|

90 m3/h

|

120 m3/h

|

180 m3/h

|

240m3/h

|

270m3/h

|

|

Model Of Mixer

|

JS1000

|

JS1500

|

JS2000

|

JS3000

|

JS4000

|

JS4500

|

|

Mixing Motor Power

|

2x18.5kw

|

2x30kw

|

2x37kw

|

2x55kw

|

2x75kw

|

2x75kw

|

|

Cycle Period

|

60s

|

60s

|

60s

|

60s

|

60s

|

60s

|

|

Volume Of Mixer

|

1000l

|

1500l

|

2000l

|

3000l

|

4000l

|

4500l

|

|

Aggregate

|

≤80mm

|

≤80mm

|

≤80mm

|

≤80mm

|

≤80mm

|

≤80mm

|

|

Volume Of Cement Silo

|

4x100t

|

4x100t

|

4x200t

|

4x200t

|

4x300t

|

4x300t

|

|

Capacity 0f Batching Plant

|

1600l

|

2400l

|

32001

|

4800l

|

6400l

|

7200l

|

|

Volume Of Aggregate Bins

|

4x8m3

|

4x12m3

|

4x20m3

|

4x25 m3

|

4*30m3

|

4*30m3

|

|

Quantity Of Aggregate

|

4

|

4

|

4

|

4

|

4

|

4

|

|

Productivity Of Aggregate Beltconveyor

|

250 m3/h

|

350 m3/h

|

500 m3/h

|

750 m3/h

|

1200 m3/h

|

1200 m3/h

|

|

Max. Productivity Of Screw Conveyor

|

40 t/h

|

80 t/h

|

80 t/h

|

110 t/h

|

160 t/h

|

160 t/h

|

|

Unloading Height

|

4.0m

|

4.0m

|

4.0m

|

4.0m

|

4.0m

|

4.0m

|

|

Total Power Of The Plant

|

150kw

|

164kw

|

210kw

|

268kw

|

363kw

|

363kw

|

|

Measuring Range And Precision Of Aggregate

|

(600-2000)≤±2%

|

(600-3000)≤±2%

|

(1000-3600)≤±2%

|

(1200-4000)≤±2%

|

(1600-6400)≤±2%

|

(1600-7200)≤±2%

|

|

Measuring Range And Precision Of Cement

|

(200-600)≤±1%

|

(200-1000)≤±1%

|

(300-1800)≤±1%

|

(300-2400)≤±1%

|

(500-3000)≤±1%

|

(600-3200)≤±1%

|

|

Measuring Range And Precision Of Coal Ash

|

(100-400)≤±1%

|

(200-600)≤±1%

|

(200-900)≤±1%

|

(200-1200)≤±1%

|

(300-1500)≤±2%

|

(400-1600)≤±2%

|

|

Measuring Range And Precision Of Water

|

(150-300)≤±1%

|

(200-500)≤±1%

|

(200-700)≤±1%

|

(200-1000)≤±1%

|

(300-1400)≤±1%

|

(360-1500)≤±1%

|

|

Measuring Range And Precision Of Admixture

|

(20-60)≤±1%

|

(20-60)≤±1%

|

(30-100)≤±1%

|

(36-120)≤±1%

|

(36-120)≤±1%

|

(36-120)≤±1%

|

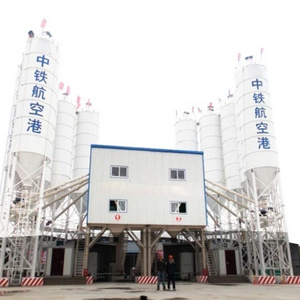

Project Cases

Our services

About us

GLOBAL ZEYU is a professional manufacturer engaged in the research development production sale and service of concrete machinery,machinery, includint quality concrete batching plant, JS concrete mixers, screw conveyor, bolted cement silo, sand stone separator, etc.

Adhering to the professional philosophy of quality-oriented, leading technology, rapid response, high-quality and advanced technology, GLOBAL ZEYU intsists creating value for customers continiously!

Hot Searches