- Product Details

- {{item.text}}

Quick Details

-

Output paper:

-

Napkin paper

-

Model Number:

-

ZD-Z4L

-

Type:

-

full automatic napkin folding machine

-

Driven Type:

-

Electric

-

Controller:

-

Frequency control

-

Diameter of jumbo roll:

-

1100mm (Other specification, please specify)

-

Max width of jumbo roll:

-

40-140 cm

-

Core inner diameter of jumbo roll:

-

76mm(Other specification, please specify)

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Field installation, commissioning and training, Online support

-

Certification:

-

ISO 9001

Quick Details

-

Production Capacity:

-

15 Set/Sets per Month

-

Place of Origin:

-

Guangxi, China

-

Name:

-

Specific Design Fold Paper Napkin Tissue Making Machine Price

-

Output paper:

-

Napkin paper

-

Model Number:

-

ZD-Z4L

-

Type:

-

full automatic napkin folding machine

-

Driven Type:

-

Electric

-

Controller:

-

Frequency control

-

Diameter of jumbo roll:

-

1100mm (Other specification, please specify)

-

Max width of jumbo roll:

-

40-140 cm

-

Core inner diameter of jumbo roll:

-

76mm(Other specification, please specify)

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Field installation, commissioning and training, Online support

-

Certification:

-

ISO 9001

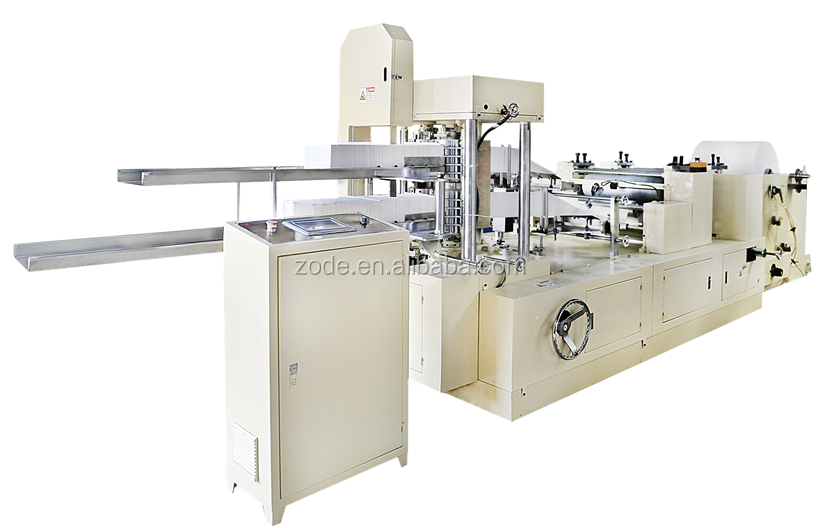

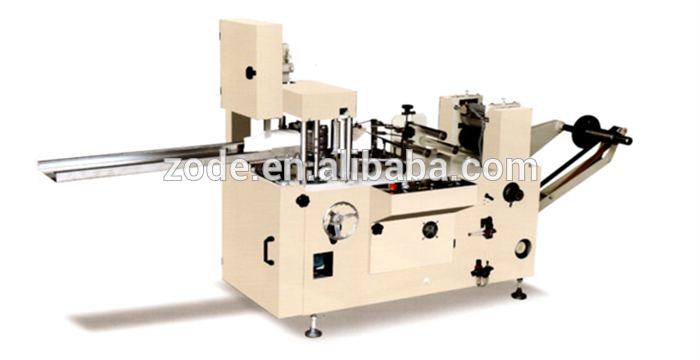

Specific Design Fold Paper Napkin Tissue Making Machine Price

olding Machine

olding Machine

Napkin paper folding printing embossing machine

ZD-Z4L napkin folding machine is using jumbo rolls as raw paper to process various sizes of napkin paper. The machine start from raw material feeding, embossment, folding and cutting to form to be one line , and then packaging. The product is of sanitation and cleanness. If customers need to produce various kind sizes ( 180 to 500) of napkin paper , the machine can be customized

|

SPECIFICATIONS |

|

|

Max width of jumbo roll |

800-1400mm |

|

Diameter of jumbo roll(mm) |

1100(Other specification, please specify) |

|

Core inner dia. of jumbo roll |

76mm(Other specification, please specify) |

|

Production speed |

0~180 meters/min. |

|

Power |

3 phase, 380V/50HZ, |

|

Controller |

Frequency control |

|

Cutting system |

point cut by pneumatic type |

|

Vacuum system |

22 KW Roots vacuum system |

|

Pneumatic system |

3P Air compressor ,minimum pressure 5kg per s quare meter Pa( prepared by customer) |

|

Host Power |

7.5kw |

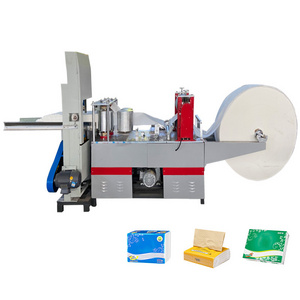

Main Features

1. Count automatically and output in order

2. Adopting screw turning knife to cut and vacuum absorption to fold.

3. Adopting step less adjusting speed to roll to fix different tension of raw paper.

4. electricty control, easy to operate.

5. This equipment can have embossing unit.

6. Wide range of production width for selection.

7. The machine can equipped with PLC according to requirement.

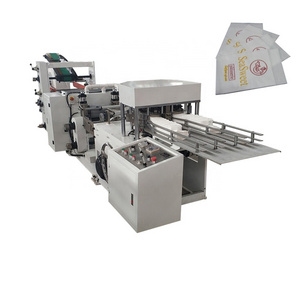

8. This machine can equip with single color and double color printing unit,the embossing

pattern have very vivid designs and beautiful colors.