- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

500*500MM, 250*250MM

-

Product name:

-

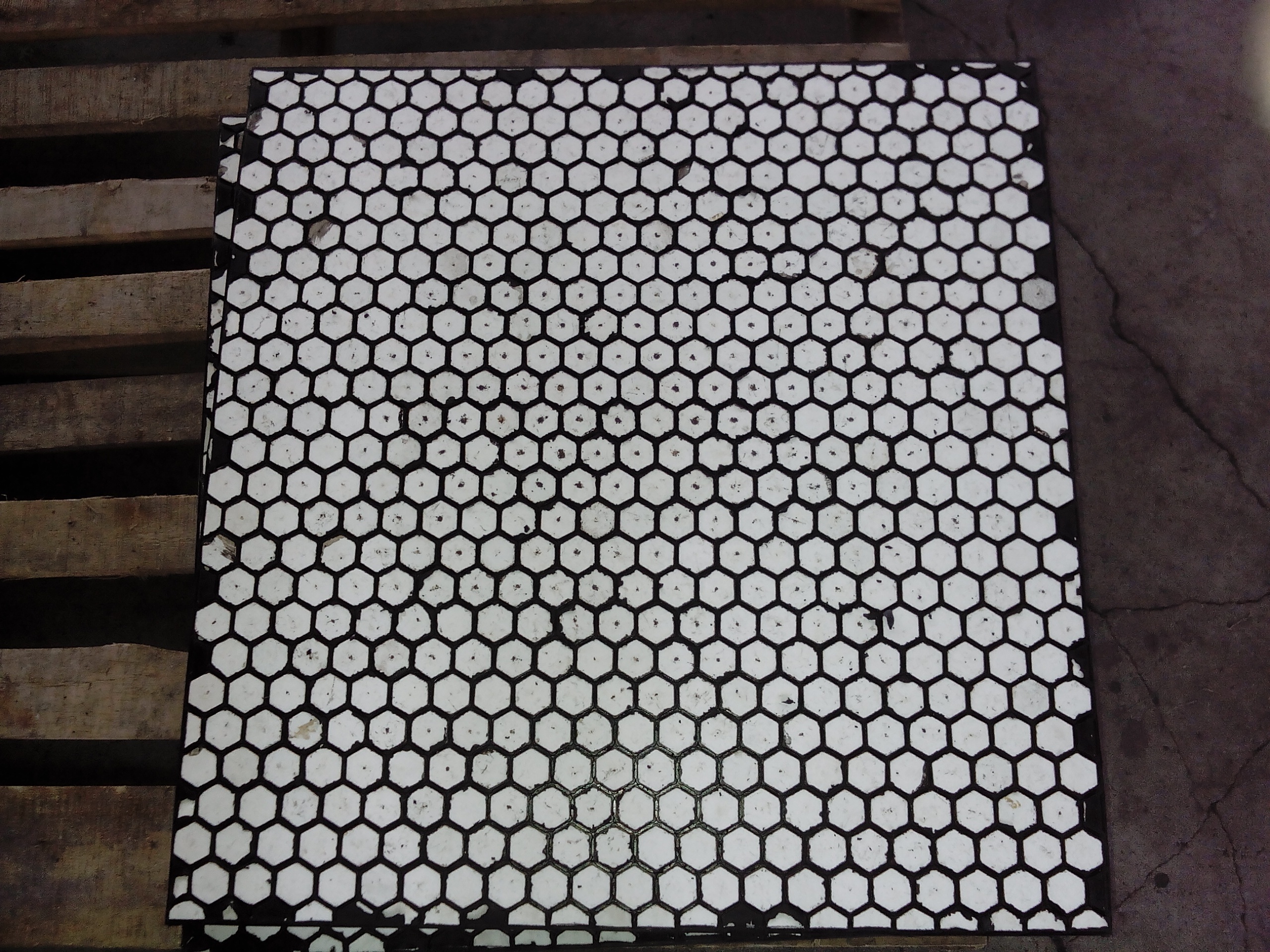

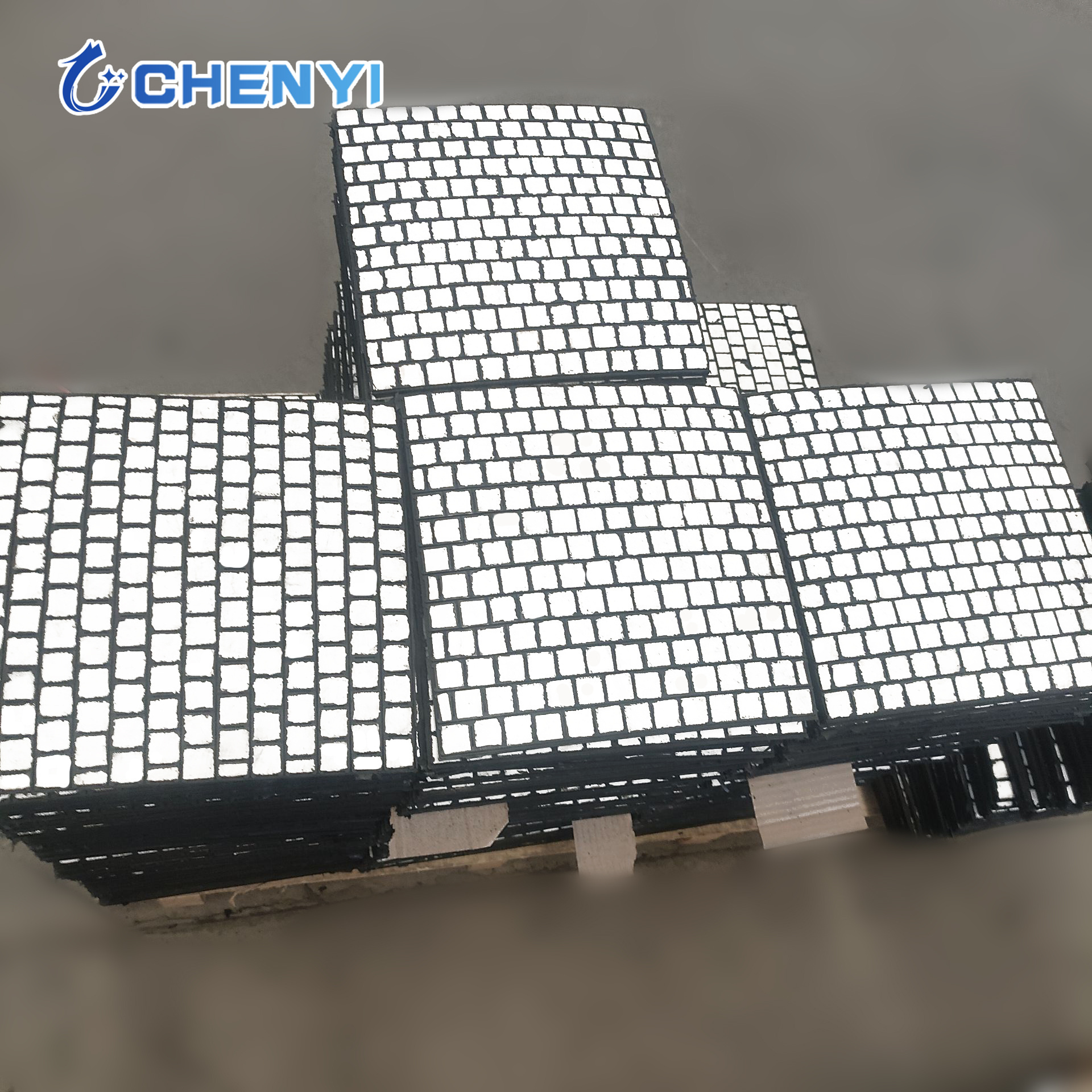

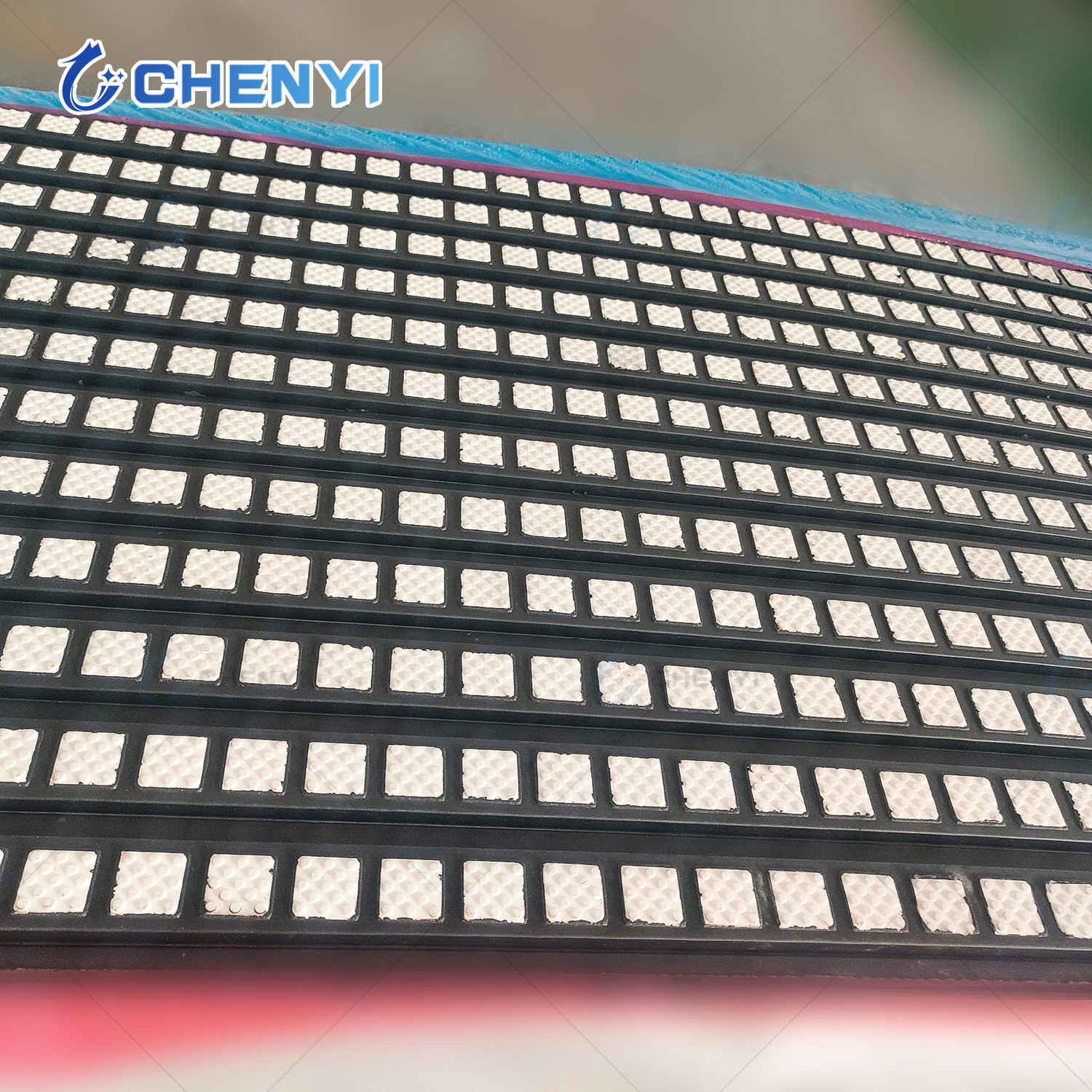

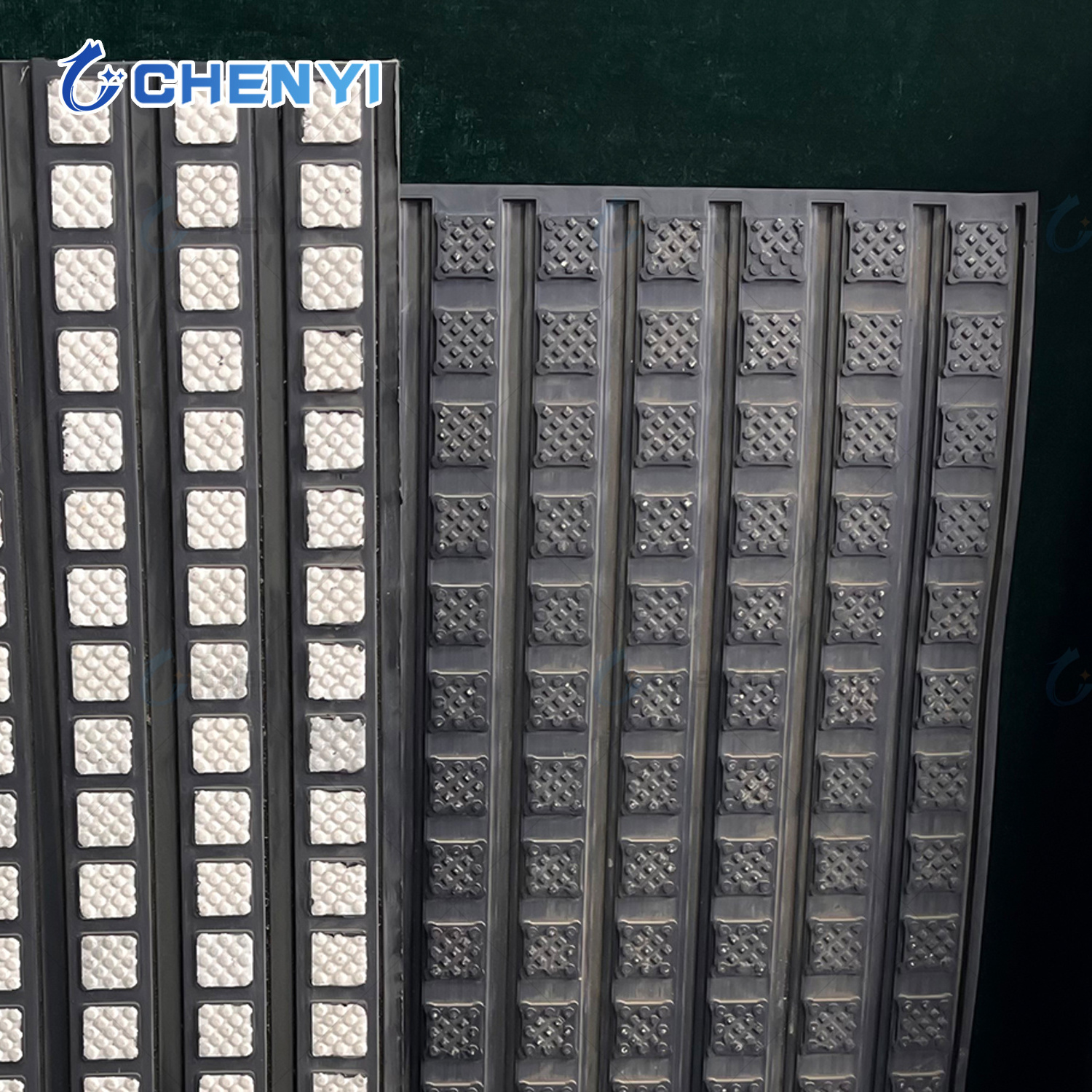

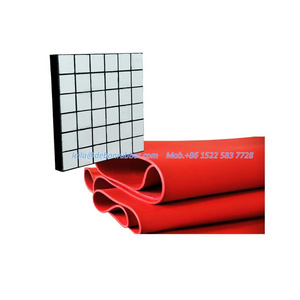

Wear-resistant panel ceramic rubber composite liner with CN layer

-

Shape:

-

square,hexgonal,cylindrical,rectangle

-

Raw material:

-

alumina ceramic

-

Process:

-

hot vulcanizing process

-

Feature:

-

excellent wear resistance

-

Tensile strength:

-

>=25Mpa

-

Shore Hardness:

-

80-90 HA

-

Alumina Content:

-

92% 95%

-

Elongation at break:

-

500%

Quick Details

-

Processing Service:

-

Cutting

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

OEM/CHENYI

-

Model Number:

-

500*500MM, 250*250MM

-

Product name:

-

Wear-resistant panel ceramic rubber composite liner with CN layer

-

Shape:

-

square,hexgonal,cylindrical,rectangle

-

Raw material:

-

alumina ceramic

-

Process:

-

hot vulcanizing process

-

Feature:

-

excellent wear resistance

-

Tensile strength:

-

>=25Mpa

-

Shore Hardness:

-

80-90 HA

-

Alumina Content:

-

92% 95%

-

Elongation at break:

-

500%

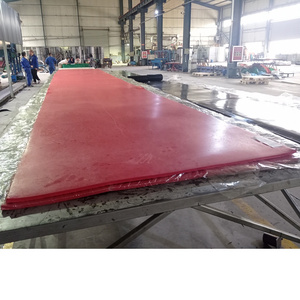

Polyurethane has high machnical strength and oxidation stability; has high flexible and resilience; has exellent oil resistance, solvent resistance, water resistance and fire resistance. Polyurethane ceramic composite sheets are more suitable for using in environmnts with high impact and poor working conditions.

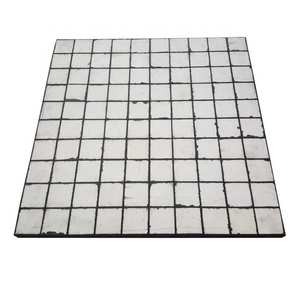

1. High alumina Rubber liner/sheet/plate

|

Product information |

||

|

Item |

Ceramic

Rubber

mats

,ceramic panel with

Rubber

,vulcanized

Rubber

ceramic liners

with steel plate,

Wear resistant liner ceramic

rubber

composite

|

|

|

HS code |

69091 1 00.00 |

|

|

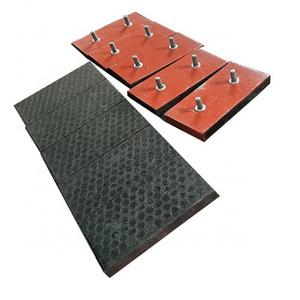

Application |

Mainly applied in mineral,harbor,iron&steel industry, the Rubber liner can efficiently buffer and decrease strong impact, the ceramic, Rubber and steel are vulcanized perfectly together, which has the privilege for abrasion-proof and anti- impact, meanwhile it is easily to be fixed in hopper ,chute ,bunker |

|

|

MOQ |

10m 2 |

|

|

Sample |

Free samples are available |

|

|

Technical data of ceramic rubber liner |

||

|

Inspecting item |

Inspecting result |

|

|

ceramic |

Al2o3(%) |

≥ 92% |

|

Density |

≥ 3.60g/cm³ |

|

|

Rockwell hardness |

≥85HRA |

|

| rubber |

Pull-apart strength |

14MPa |

| Pull-apart prolongation | 250% | |

| Shore hardness | 55-65 | |

| Permanent deform |

0.0005g (P=74N,n=800rpm,t=30min, quartz sand ) |

|

|

Ceramic abrasion test |

0.0005g (P=74N,n=800rpm,t=30min, quartz sand ) |

|

|

Elogation |

500% | |

|

Adhesion of adhesive agent and ceramic |

4MPa |

|

| Temperature |

≤ 100 ℃ |

|