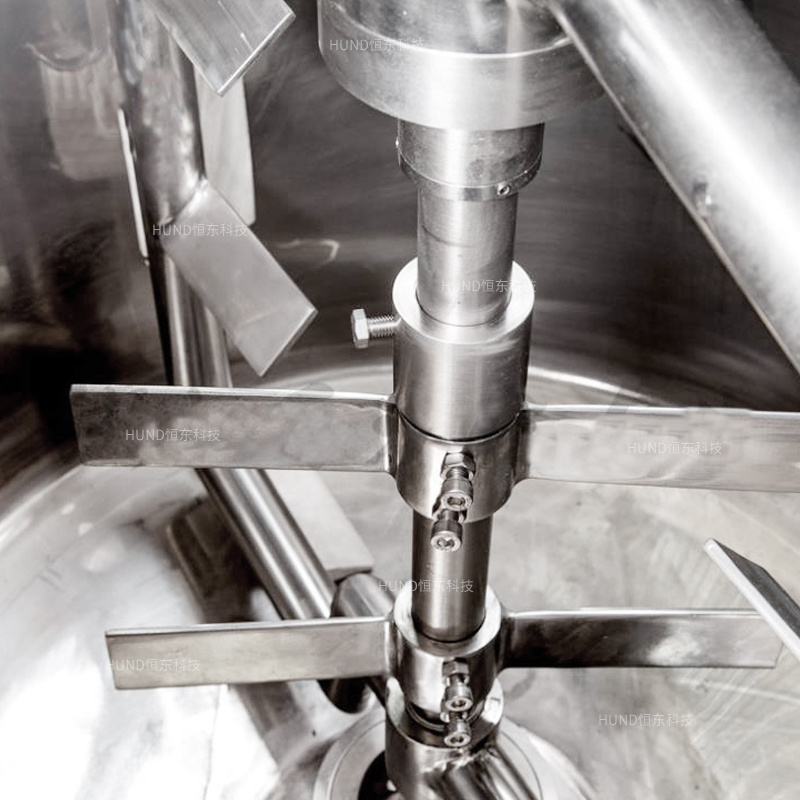

Anchor with scrapers

Frame with scrapers

Dispenser(single/

double/three layers

)

Triple

impeller(double/three layers)

Turbine disk

P

itched paddles

Ribbon mixer

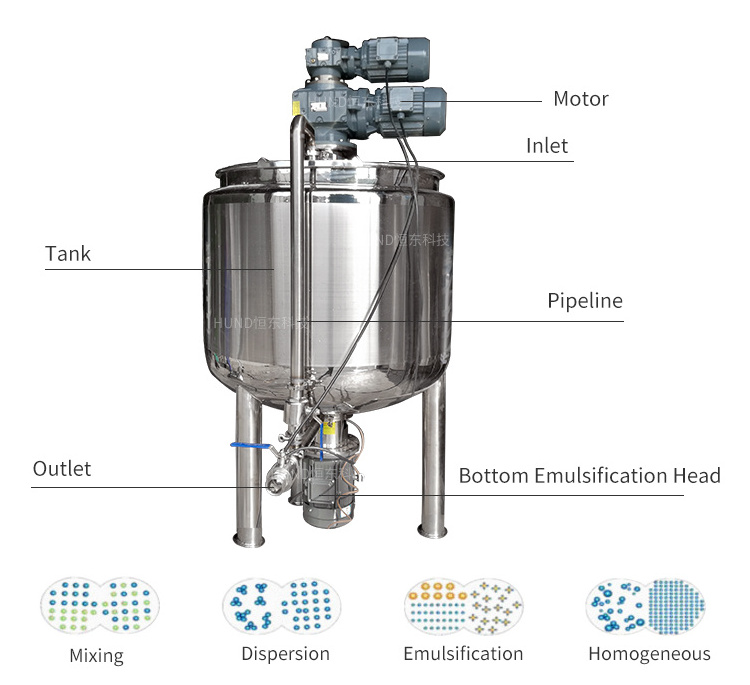

Top entry high shear emulsifier

Bottom entry high shear emulsifier

Anchor+

Dispenser

Anchor+ Top e

mulsifier

Anchor+ Bottom emulsifier

A

nchor+ Emulsifier+

Dispenser

Anchor+ Emulsifier+

Pitched paddles

(one-direction/

Coaxial double-direction

)

......