Press felt section

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Paper Industry

-

Function:

-

removing the water from the paper web

-

Weight:

-

700-1200gsm

-

Type:

-

Nonwoven

-

Material:

-

100% Polyester

-

Usage:

-

paper forming section, press section

-

After Warranty Service:

-

Video technical support, Online support, Field maintenance and repair service

-

Local Service Location:

-

Egypt, United States, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Malaysia, Australia, Morocco, Kenya, Argentina, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Guangmao Machinery

-

Name:

-

paper making machine mill press polyester felt fabric

-

Application:

-

Paper Industry

-

Function:

-

removing the water from the paper web

-

Weight:

-

700-1200gsm

-

Type:

-

Nonwoven

-

Material:

-

100% Polyester

-

Usage:

-

paper forming section, press section

-

After Warranty Service:

-

Video technical support, Online support, Field maintenance and repair service

-

Local Service Location:

-

Egypt, United States, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Malaysia, Australia, Morocco, Kenya, Argentina, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

paper making machine mill press polyester felt fabric

Product Description

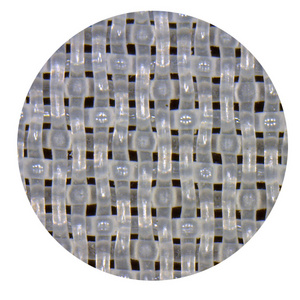

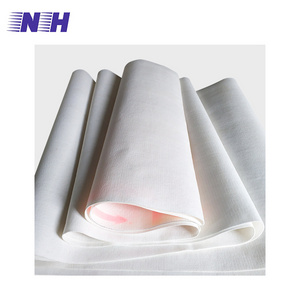

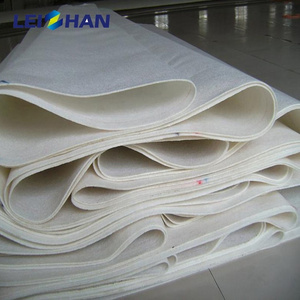

Brief Introduction of Paper Making Felt:

The press felt an important role in removing the water from the paper web after the forming section, and at the same time

imparting smoothness and conveying it to the dryer section. For this reason, the press felt needs to provide the following functions: water removal, smoothness and runnability. In recent years, larger and faster paper machines require press felts of even higher consistency and quality.

imparting smoothness and conveying it to the dryer section. For this reason, the press felt needs to provide the following functions: water removal, smoothness and runnability. In recent years, larger and faster paper machines require press felts of even higher consistency and quality.

|

Product Name

|

BOM felt , single layer , double layer, triple layer of paper making felt

|

|

|

|

|

use position

|

pickup felt ,MG felt ,dryer felt ,press felt

|

|

|

|

|

Material

|

Nylon / Synthetic Filament Or Multi-filament

|

|

|

|

|

Paper machine

|

Cylinder \Super forming\ Fourdrinier\ Inclined wire machine\ Nip wire machine for forming section felt \ Press felt

|

|

|

|

|

Machine Velocity

|

≤ 800m/min

|

|

|

|

|

Paper

|

≥8g/m2 kinds of Paper

|

|

|

|

|

Feature:

|

Less Elongation

Easy to CleanNo-mark on paper Good filtration |

|

|

|

|

Service life

|

3 months - 9 months

|

|

|

|

|

BOM TECHNICAL PARAMETER

|

Felt GSM: 700-1200g/m2Felt GSM Tolerance:≤±4%

Air permeability: 30-120cfm Tensile Strength: ≥2000N/5cm Elongation Percentage: ≤ 1% Width Variation: ≤±2cm |

|

|

|

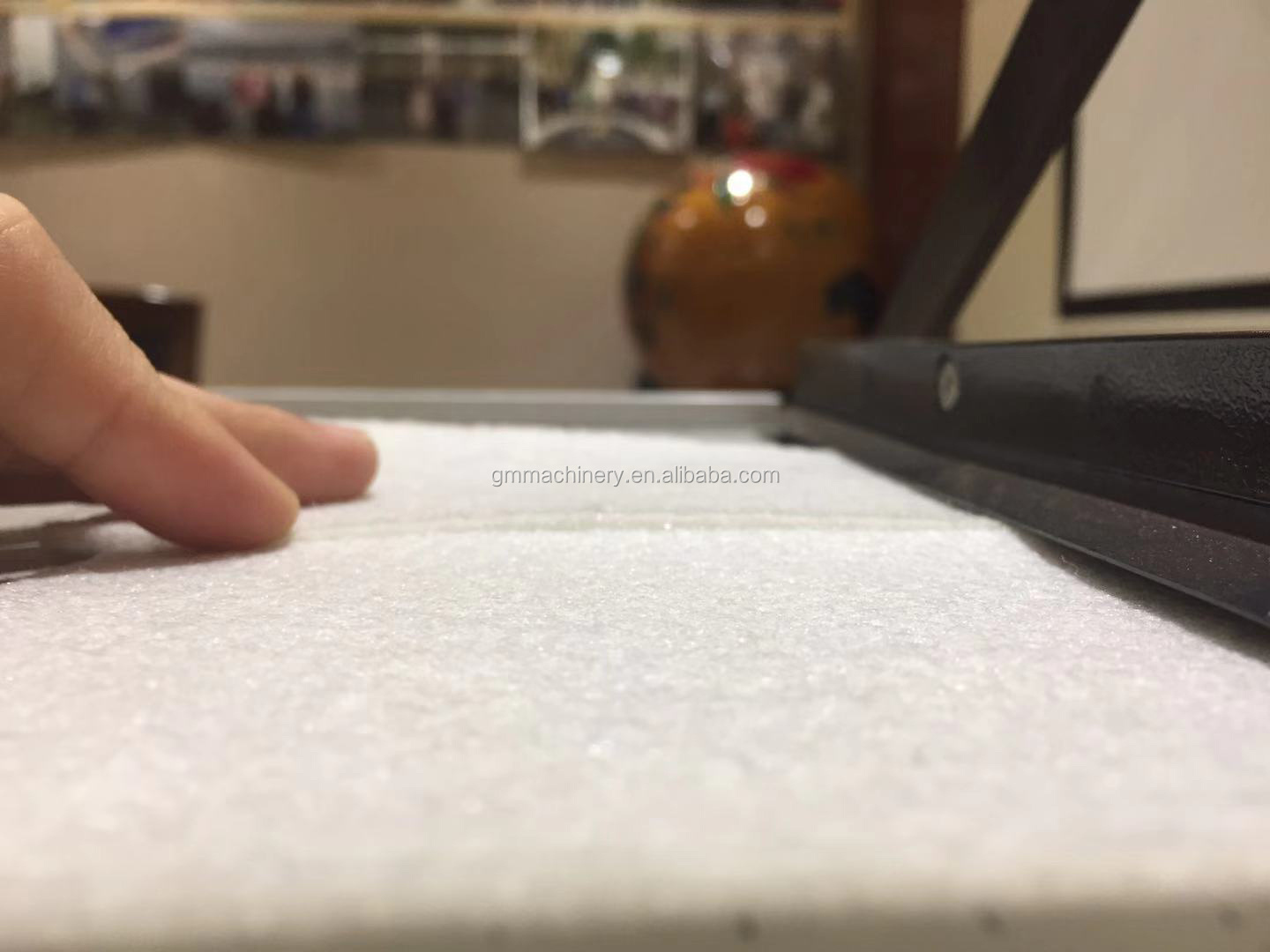

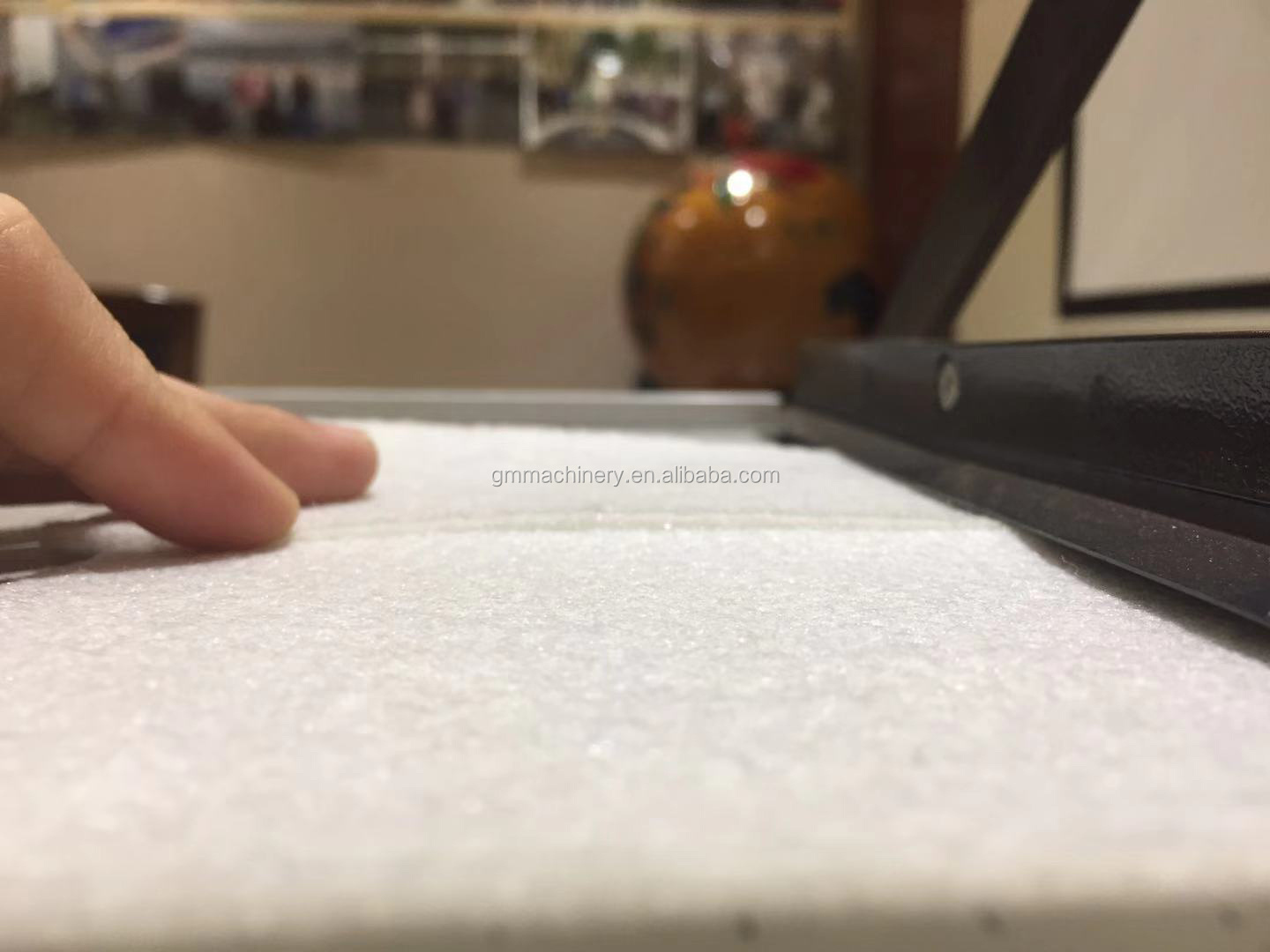

Details Images

Advantages of GM Paper Making Felt:

1. High anti-compaction capacity.

2. Extremely high elasticity and recoverability.

3. Strong drainability abd larger void volumn.

4. Long holding time of wear resistance and plastic strength of felt.

5. Smooth felt surface and even pressure distribution.

2. Extremely high elasticity and recoverability.

3. Strong drainability abd larger void volumn.

4. Long holding time of wear resistance and plastic strength of felt.

5. Smooth felt surface and even pressure distribution.

Installation Sites

GM3200mm Offset Printing Paper Machine For Uzbekistan Client

GM1575mm White Paper Making Machine For Moroccan Client

Cylinder Mould And Felt Section

GM1880mm Toilet Tissue Paper Making Machine For Egyptian Client

Dryer Cylinder Felt Section

Product packaging

Hot Searches