- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

JH21-160T

-

Weight (T):

-

14.5

-

Marketing Type:

-

New Product 2022

-

Warranty of core components:

-

24 months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Closed height:

-

400mm for pneumatic press

-

Product name:

-

can be customized punch

-

Power Press machine:

-

punching machine auto line

-

Function:

-

Punching Ang Press

-

Material:

-

Hard Steel for pneumatic punch

-

Name:

-

Metal Stamping Press

-

Application:

-

press machine for hole punching shape forming

-

Usage:

-

Pressing Metal Products

-

Nominal Force (kN):

-

1600KN auto press power machine

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

rbqlty

-

Dimension(L*W*H):

-

2600*1540*3800mm

-

Model Number:

-

JH21-160T

-

Weight (T):

-

14.5

-

Marketing Type:

-

New Product 2022

-

Warranty of core components:

-

24 months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Closed height:

-

400mm for pneumatic press

-

Product name:

-

can be customized punch

-

Power Press machine:

-

punching machine auto line

-

Function:

-

Punching Ang Press

-

Material:

-

Hard Steel for pneumatic punch

-

Name:

-

Metal Stamping Press

-

Application:

-

press machine for hole punching shape forming

-

Usage:

-

Pressing Metal Products

-

Nominal Force (kN):

-

1600KN auto press power machine

Order process

1. Confirmation of machine model

International Marketing and Technology Department

2. Confirm mold (workpiece drawing, material, thickness)

International Marketing and Technology Department

3. Confirm order and arrange payment

Finance Department

4. Engineer to provide drawing confirmation

Technical Department(6

engineers

)

5. Arrange production

Production department

6. Provide sample and sample test certificate (sample can be sent)

QC quality inspection

7. Confirm delivery

Documentation department is responsible for shipping the goods

8. Lifetime after-sales

After sale service department

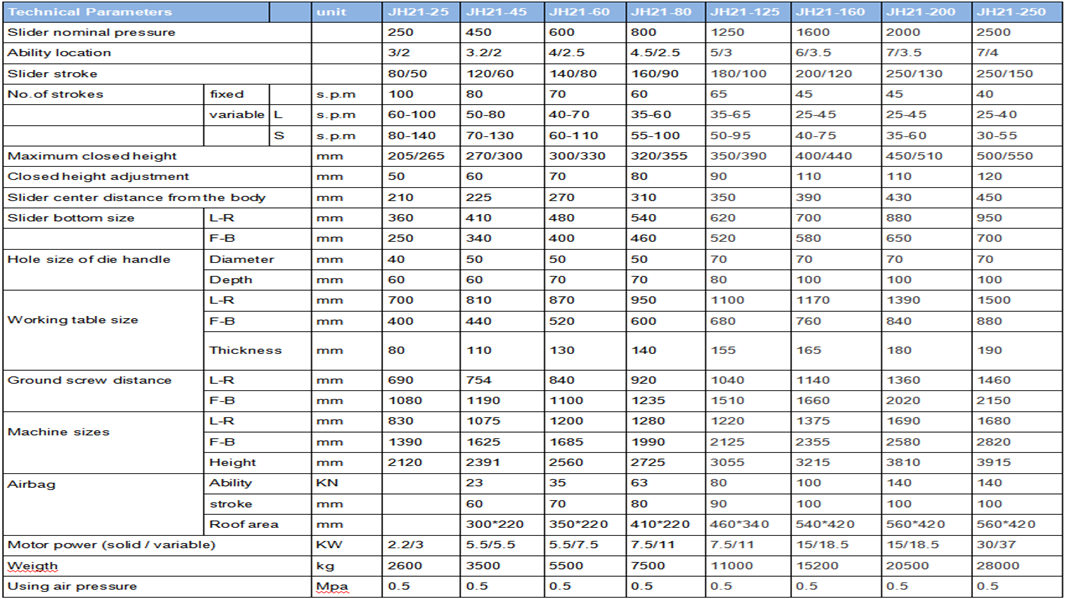

Product informations

Rbqlty full automatic feeder with press machine pneumatic hole punching machine 2022 spring new

Heavy, one-piece welded steel frame is designed to resist deflection, give more accurate stampings and longer die life.

Fast-response hydraulic overload relieves the pressure of a tonnage overload in milliseconds, stopping the press immediately and

protecting press and dies from damage.

Wet clutch and brake provide long life, very low maintenance, and high performance even at high single-stroking rates.

•JIS I accuracy.

•Steel welded frame with high rigidity.

•Motor with inverter.

•Combined wet friction clutch.

•Rectangular hexahedral lengthened guide; JH21-315/400 with octahedral lengthened guide.

•Hydraulic overload protector.

•Lifting balance cylinder.

•Imported dual solenoid valve.

•Elec.forced grease lubrication.

•Balance cylinder: manual oil lubrication.

•Integrated panel (elec.cam included).

•PLC control of international brand.

•Contactor and button of international brand.

•CE safety specifications

•Optional: air cushion, light curtain, automotive device.

Fast-response hydraulic overload relieves the pressure of a tonnage overload in milliseconds, stopping the press immediately and

protecting press and dies from damage.

Wet clutch and brake provide long life, very low maintenance, and high performance even at high single-stroking rates.

•JIS I accuracy.

•Steel welded frame with high rigidity.

•Motor with inverter.

•Combined wet friction clutch.

•Rectangular hexahedral lengthened guide; JH21-315/400 with octahedral lengthened guide.

•Hydraulic overload protector.

•Lifting balance cylinder.

•Imported dual solenoid valve.

•Elec.forced grease lubrication.

•Balance cylinder: manual oil lubrication.

•Integrated panel (elec.cam included).

•PLC control of international brand.

•Contactor and button of international brand.

•CE safety specifications

•Optional: air cushion, light curtain, automotive device.

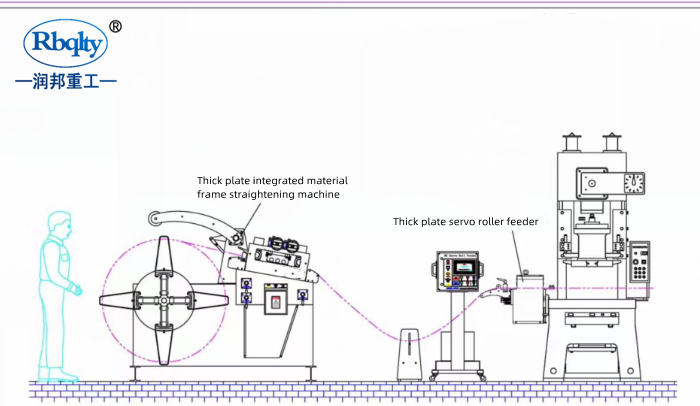

Automatic feeder of punching machine

It can be matched with the feeder at the same time, providing work efficiency and output, and reducing labor costs. At the same

time, we have an excellent technical team, which can customize the mold according to the workpiece and match the whole production

line scheme.Pneumatic punching machine have passed CE certification and have the most authoritative quality reports. Each machine

is provided with a certificate of conformity, and will provide you with the best after-sales service in the warranty.

Our engineer can according to your product or wokpiece drawing to recommend the autoduction production line,the machine is applicable to metal and non-metal industries, our company has a professional technical team, which can provide professional

solutions within one day according to your workpiece.We have had many successful cases in different countries, and in the field of

molds, we have a good reputation in the industry.

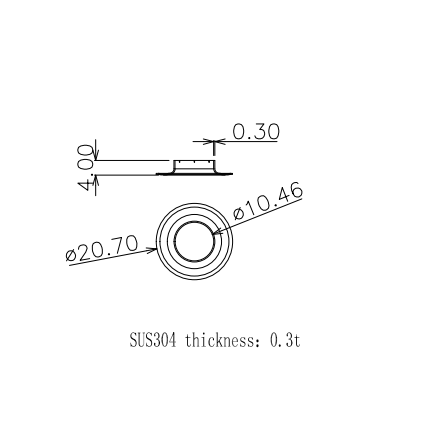

The following are the workpiece drawings and the actual mold drawings provided by our engineers based on the customer's

workpieces. You only need to provide the workpiece drawings and detailed sheet information, and our professional team can provide

the most complete and most suitable for you according to your output value requirements. .

It can be matched with the feeder at the same time, providing work efficiency and output, and reducing labor costs. At the same

time, we have an excellent technical team, which can customize the mold according to the workpiece and match the whole production

line scheme.Pneumatic punching machine have passed CE certification and have the most authoritative quality reports. Each machine

is provided with a certificate of conformity, and will provide you with the best after-sales service in the warranty.

Our engineer can according to your product or wokpiece drawing to recommend the autoduction production line,the machine is applicable to metal and non-metal industries, our company has a professional technical team, which can provide professional

solutions within one day according to your workpiece.We have had many successful cases in different countries, and in the field of

molds, we have a good reputation in the industry.

The following are the workpiece drawings and the actual mold drawings provided by our engineers based on the customer's

workpieces. You only need to provide the workpiece drawings and detailed sheet information, and our professional team can provide

the most complete and most suitable for you according to your output value requirements. .

At the same time, our pneumatic punching machine can also be used with different feeders. Our engineers will provide you with a

suitable feeder and a fully automatic production line according to your processing accuracy requirements, production and output

requirements.

Our pneumatic press machine wiring diagram and floor area map are for reference. After the machine is completed, we will provide a

full set of instructions, circuit diagrams and floor space.

suitable feeder and a fully automatic production line according to your processing accuracy requirements, production and output

requirements.

Our pneumatic press machine wiring diagram and floor area map are for reference. After the machine is completed, we will provide a

full set of instructions, circuit diagrams and floor space.

Automatic feeder for coil.

Pls provide material,thickness,width and coil weight,then we will recommend suitable model

Automatic feeder for plate

Pls provide material,thickness,width and lengththen we will recommend suitable model

Automatic feeder.

ide provide need model or requirments,then we will quotate

s.

Details

Other solution of cnc punching line for different material form: (CNC pneumatic punch with auto robot/ high performance press punching machine with plate cnc feeder)

Control Panel

PLC for pneumatic press machine

Hydraulic overload protection

Prevent overloading of the machine

Siemens motor

Motor for pneumatic press machine

Electric components

Estun Omron Schneider

lubrication system

for clutch

Air cylinder

for pneumatic press machine

Frequency converter

Taiwan Delta brand.

Counter

stro,ke counting

Bolster plate

for mold

Anhui Runbang Heavy Industry Machinery Co., Ltd.

Anhui Runbang Heavy Industry Machinery Co.,Ltd concentrates on the research, development, manufacture, sale and service in metal

fabrication equipment. Rbqlty focus on CNC fiber laser cutting, cnc bending,shearing,rolling punching and duct machines. with more

than 160 countries export experience. Support you factories building and whole saler market enlarging! Rbqlty is our registered

brand trademark. it represents Runbang and Quality. Runbang is a company that develops quickly by product quality. We strive to

supply you best quality machine tool by our scientific management , advanced technology , novel design, reasonable price and

perfect service. Sincerely looking forward to developing with you together!

Anhui Runbang Heavy Industry Machinery Co.,Ltd concentrates on the research, development, manufacture, sale and service in metal

fabrication equipment. Rbqlty focus on CNC fiber laser cutting, cnc bending,shearing,rolling punching and duct machines. with more

than 160 countries export experience. Support you factories building and whole saler market enlarging! Rbqlty is our registered

brand trademark. it represents Runbang and Quality. Runbang is a company that develops quickly by product quality. We strive to

supply you best quality machine tool by our scientific management , advanced technology , novel design, reasonable price and

perfect service. Sincerely looking forward to developing with you together!

Our service for you:

Runbang bases on High quality machine, Supreme service! 1. Expert sales team: Ensure fast&right reply! 2. Experienced technical

team: Ensure expert&targeted offer! 3.Perfect after-sales team: Ensure smooth&fast usage!4.Our machine has 2 year warranty,except

spare parts,lifelong maintain,

5.we have professional documents department,provide all the documents for clearance custom,PL.BL,CO,Form E,Form A and other

special documents. 6.we have professional after sale service department,when you got the machine,have some questions for

operation,our college and engineer will teach you how to use on line 7.Now we have more than 30 agents in South-east,

Europe,Mid-east,South America and also Africa. We are looking for more agents in different countries

8.After place an order,we will make a group with you,our engineer,after sale service department and shipping department,our whole

team will support for you.

Choosing us is choosing a guarantee!Welcome to sent inquiry to us!

Runbang bases on High quality machine, Supreme service! 1. Expert sales team: Ensure fast&right reply! 2. Experienced technical

team: Ensure expert&targeted offer! 3.Perfect after-sales team: Ensure smooth&fast usage!4.Our machine has 2 year warranty,except

spare parts,lifelong maintain,

5.we have professional documents department,provide all the documents for clearance custom,PL.BL,CO,Form E,Form A and other

special documents. 6.we have professional after sale service department,when you got the machine,have some questions for

operation,our college and engineer will teach you how to use on line 7.Now we have more than 30 agents in South-east,

Europe,Mid-east,South America and also Africa. We are looking for more agents in different countries

8.After place an order,we will make a group with you,our engineer,after sale service department and shipping department,our whole

team will support for you.

Choosing us is choosing a guarantee!Welcome to sent inquiry to us!

Contact us

Our customer come to our factory for visiting factory,inspection machine and place an orderAny inquiry or interested,welcome to inqury for us.

Hot Searches