- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Strong

-

Model Number:

-

58585

-

material:

-

EPP,EPE,EVA,PVC,PE,etc

-

Use:

-

Case, tool, bag

-

Hardness:

-

Shore 10-90

-

COLOR:

-

multicolor according to customer's requirement

-

Thickness:

-

2-100mm

-

Size:

-

Customized size or suggested size by our engineer

-

Product name:

-

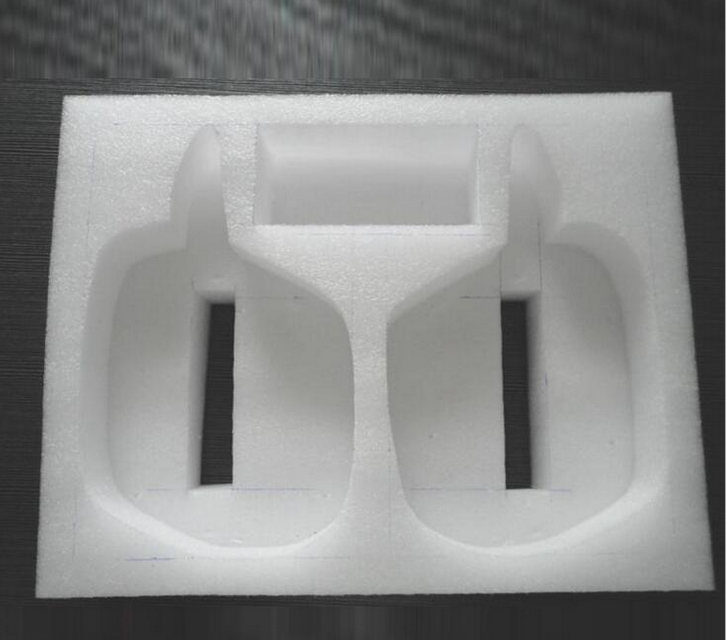

epp foam box

Quick Details

-

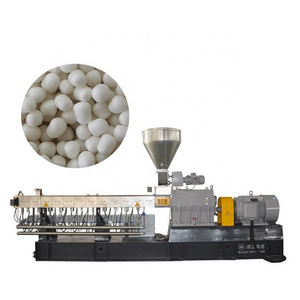

Material:

-

EPS Foam

-

Type:

-

Foam

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Strong

-

Model Number:

-

58585

-

material:

-

EPP,EPE,EVA,PVC,PE,etc

-

Use:

-

Case, tool, bag

-

Hardness:

-

Shore 10-90

-

COLOR:

-

multicolor according to customer's requirement

-

Thickness:

-

2-100mm

-

Size:

-

Customized size or suggested size by our engineer

-

Product name:

-

epp foam box

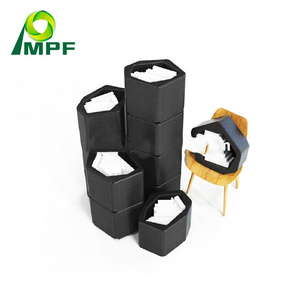

epp foam box

◊ Features

-

Waterproof and shockproof materials.

-

Corrosion resistance.

-

Sound insulation.

- T hermal insulation.

- Processibilit.

◊ Application

Applied in noise reduction of mill construction, building, product package & liner, generator set, air condition , acoustics laboratory, music recording studio, loudspeaker box, audition room, studio, mapping room, KTV, grand hotel, etc.

| Product Name: | epp foam box |

| Product Size: | Customized |

| Thickness: | From 2mm~100mm |

| Hardness: | 10°~90° |

| color: | any color is available |

| Prinitng: | Screen print |

| Application: |

1.protect your products very well to avoide any destroy. 2.soft beautful design ,shine your products. 3. Different grade material,according to your choice. |

| Package: | PE films,export cartons. |

FAQ:

Q1. When can I get the price?

A: We usually quote within 2 days after we get your inquiry. If you are very urgent, please call us or tell us in your email so that we will regard your inquiry priority.

Q2. How long is the lead-time for mold?

A: It all depends on the mold’s size and complexity. Normally, the lead time is 25—35days.

If the molds are very simple and not big size, we can work out within 15 days.

Q3. I have no 3D drawing, how should I start the new project?

A: You can supply us a sample, we will help you finish the 3D drawing design.

Q4. Before shipment, how to make sure the products quality?

A:If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker. We will supply you a video for production process detail include process report, products size ,structure and surface detail, packing detail and so on.

Q5.Can you do post production?

A:Some customers in addition to plastic injection require post processing, assembly of their products and packaging.

We have done this numerous times and have the facility and staff ready for these processes. You are welcome to inquire about post production if you need it. Or send us a quote request for any part you need. Wewill be happy to assist you with the quote or any technical, packaging, post processing or shipping inquiry.

1,Experience: more than ten years manufacturing history;

2,Price : Reasonable and competitive according to your drawings;

3,quality assurance: To ensure correct standard and choose equivalent stansard for materail and technique requirements,before running ,we would like to provide formal material certificate showing chemical compositions and property,also if you need ,we can provide control plan,showing processing and inspection tooling;

4,quanlity control: In house,coming inspection,first off,spotcheck in processing ,final inspection, 100% inspection for critical dimension;

5,Small order accepted;

6,packing: carton box or iron can or depend on your requirements;

7,Delivery: 20-30days after confirming order, according to your requirements and production quantity:

8,Payment: By T/T, for samples 100% with the order: for production,50%paid for deposit by T/T before production arrangement, the balance to be paid before shipment. or negotiation;

9,honesty and professional services;

10,Product application: Home appliance equipment, Auto parts, Industrial equipment, Electrical equipment, mechanical parts, hardware parts.