- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Power:

-

0.75kw

-

Weight:

-

300 KG

-

Dimension(L*W*H):

-

1560*450*1340mm

-

Year:

-

newest

-

Product name:

-

potato blanching machine

-

Material:

-

304 Stainless Steel

-

Quality:

-

top level

-

Operation:

-

so easy

-

Production Capacity:

-

100-500kg/hr

-

Advantage:

-

high effiency

-

Raw material:

-

Fresh Potato

-

Service:

-

24hours on line

-

Mobile/Wechat/WhatsApp:

-

0086 18092951870

-

Skype:

-

amysilkroad

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SR

-

Type:

-

potato blanching machine

-

Voltage:

-

Customized

-

Power:

-

0.75kw

-

Weight:

-

300 KG

-

Dimension(L*W*H):

-

1560*450*1340mm

-

Year:

-

newest

-

Product name:

-

potato blanching machine

-

Material:

-

304 Stainless Steel

-

Quality:

-

top level

-

Operation:

-

so easy

-

Production Capacity:

-

100-500kg/hr

-

Advantage:

-

high effiency

-

Raw material:

-

Fresh Potato

-

Service:

-

24hours on line

-

Mobile/Wechat/WhatsApp:

-

0086 18092951870

-

Skype:

-

amysilkroad

Hot Sale potato blanching machine

Introduction of potato chip s making machine:

Potato chips machine is one kind of snacks processing machine from fresh potato after washing, peeling, slicing, frying and flavoring.

The potato chips processed by potato chips making machine have the special delicious flavor of roasted patato, and the rich nutrition remains.

Potato chips is very popular with all range of people all over the world, so our potato chips making machine is also very popular among the customers all over the world.

Features of potato chip s making machine:

1. The main parts of whole production line of potato chip machine is made of FOOD GRADE 304# stainless steel, which is healthy for people;

2. The stainless steel is easy to clean and durable;

3. The potato chips is one most of the popular snacks, low investment can make big profit, so the potato chip machine is your best business partner;

4. No pollution: potato chip machine adopts the water and oil mixed principle to fry the chips, so there's no smoke or lampblack produced in the working;

5. The temperature, frying time and deoiling time are controlled by the computer;

6. Automatic deischarging system can reduce the labor intensity of the workers and improve the product quality.

Raw material of potato chip s making machine:

The raw material can be fresh potato, also can be some other root vegetables, such as sweet potatoes, purple sweet potato,taro,cassava etc.

Flowchart of potato chip s making machine:

Peeling --- slicing --- blanching --- dewatering --- frying --- deoiling --- flavoring --- packing

1.Cleaning and peeling machine:

wash and peel the potatoes automatically.

2.Slicing machine:

slice the potatoes into potato chips, potato strips, french fries, potato fingers and so on. The surface appears smooth and the shapes are uniform.

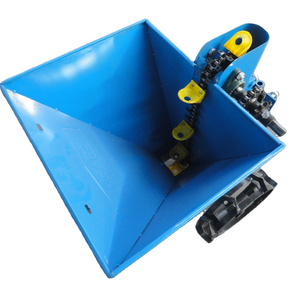

3.Rinsing(blanching) machine:

Rinse or blanch the shaped chips to keep the chips in beautiful color.

4.Dewarting machine:

Remove the water of potato chips after rinsing, prepare for the frying.

5.Frying machine:

Fry the potato chips until them become golden and soft.

6.Deoiling machine:

Remove the extra oil after frying to make the food crisp and good taste.

7.Flavoring machine:

According to your individual flavor to season the potato chips.

8.Packing machine:

Pack the potato chips, potato crisps into nitrogen bags to keep them in good flavor.

Parameters of potato chip s making machine:

|

Machines |

Model |

Motor |

Size(mm) |

|

Cleaning and Peeling machine |

S R TP-30 |

1.1kw/380v |

720*680*850 |

|

Potato chips cutting machine |

S R QS-400 |

1.5kw/380V |

730*590*860 |

|

Blanching machine |

SR PT-1000 |

15kw/380v |

1350*650*700 |

|

Dewater machine |

SR TS-500 |

0.75kw/380v |

940*830*560 |

|

Frying machine |

SR DY-500 |

9kw/380v |

580*620*950 |

|

De-oiling machine: |

SR TY-500 |

0.75kw/380v |

940*830*560 |

|

Seasoning machine |

SRS --500 |

0.75kw/220v |

1000*800*1350 |

|

Packing machine |

SR DZ-400 |

1.1kw/220v |

1220*800*900 |

More photos of potato chip s making machine:

Send your inquiry details in the below,click " Send "Now.

Or contact us in the following ways: