- Product Details

- {{item.text}}

Quick Details

-

Grade:

-

gr5 titanium welding wire

-

Ti (Min):

-

99.6%

-

Strength:

-

140-830MPa

-

Product name::

-

titanium wire

-

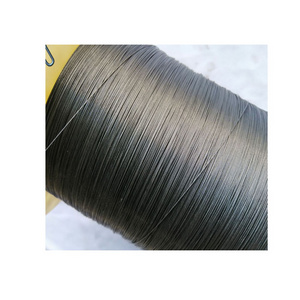

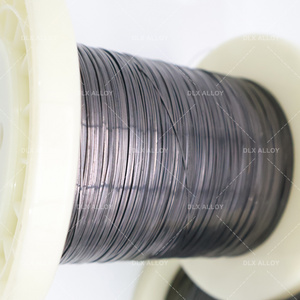

surface:

-

Black & Polished

-

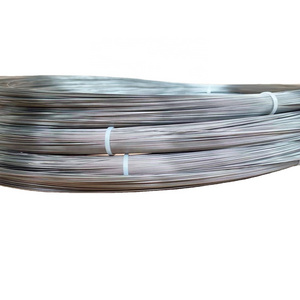

shape:

-

wire in spool,wire in coil,straight

-

density:

-

4.51g/cm3

-

MOQ:

-

3kg

-

Melting Point:

-

1668 °C

-

Wire Gauge::

-

0.05~20mm

-

Condition::

-

hard (Y)/ Soft (M)/Half Hard (Y2)

-

Technique::

-

Drawing And Rolling

-

Delivery Time::

-

7-20 Days

Quick Details

-

Application:

-

Industrial&Medical implants&Glass

-

Place of Origin:

-

Shanghai, China

-

Model Number:

-

ta1 titanium welding wire

-

Grade:

-

gr5 titanium welding wire

-

Ti (Min):

-

99.6%

-

Strength:

-

140-830MPa

-

Product name::

-

titanium wire

-

surface:

-

Black & Polished

-

shape:

-

wire in spool,wire in coil,straight

-

density:

-

4.51g/cm3

-

MOQ:

-

3kg

-

Melting Point:

-

1668 °C

-

Wire Gauge::

-

0.05~20mm

-

Condition::

-

hard (Y)/ Soft (M)/Half Hard (Y2)

-

Technique::

-

Drawing And Rolling

-

Delivery Time::

-

7-20 Days

Product Show

super elastic nitinol glasses frame nitinol flat wire from china

Products Description

1.Standard:ASTMF2063-12

2.wire size range: Dia0.08mm-6mm

3.Surface: light oxide/black/ polished

4.AF range:-20-100 Degree ℃

5.Density:6.45g/cc

6.Feature: superelastic/ shape memory

Nitinol (Nickel and titanium alloy) introduction:

Nickel Titanium (also known as Nitinol or NiTi) is in the unique class of shape memory alloys. A thermoelastic martensitic phase transformation in the material is responsible for its extraordinary properties. Nitinol alloys are typically made of 55%-56% Nickel and 44%-45% Titanium. Small changes in composition can significantly impact the properties of the material.Superelastic nitinol wire 2mm for sale

There are two primary categories of Nitinol. The first, known as "SuperElastic", is characterized by extraordinary recoverable strains and kink resistance. The second category, "Shape Memory" alloys, is valued for the Nitinol's capacity to recover a pre-set shape when heated above its transformation temprature. The first category is often used for orthodontics (braces, wires, etc) and eyeglasses. The first category are primarily useful for actuators, used in many different mechanical devices.

Nickel Titanium (also known as Nitinol or NiTi) is in the unique class of shape memory alloys. A thermoelastic martensitic phase transformation in the material is responsible for its extraordinary properties. Nitinol alloys are typically made of 55%-56% Nickel and 44%-45% Titanium. Small changes in composition can significantly impact the properties of the material.Superelastic nitinol wire 2mm for sale

There are two primary categories of Nitinol. The first, known as "SuperElastic", is characterized by extraordinary recoverable strains and kink resistance. The second category, "Shape Memory" alloys, is valued for the Nitinol's capacity to recover a pre-set shape when heated above its transformation temprature. The first category is often used for orthodontics (braces, wires, etc) and eyeglasses. The first category are primarily useful for actuators, used in many different mechanical devices.

|

Product

|

titanium welding wire

|

|

Size

|

Straight:

|

|

|

Dia.: 1.0mm-5.0mm (0.04"-0.02", tolerance: +/-0.05mm, +/-0.002")

|

|

|

3000mm (118") max length

|

|

|

Coiled:

|

|

|

Dia.: 0.5mm-5.0mm (0.02", tolerance: +/-0.05mm, +/-0.002")

|

|

|

Spool diameter: around 300mm (12")

|

|

Material

|

Gr.1, Gr.2, Gr.3, Gr.4, Gr.5, Gr.7, Gr.9, Gr.12

|

|

Standard

|

ASTM B863, ASTM F67, AWS 5.16, etc.

|

|

Surface

|

Black, Pickled, Polished (for dia. >1mm)

|

|

Shape

|

Straight or Coiled

|

Applications:

aerospace alloys andapplications

medical implants

piercing% accessory

optical frames

surgical instruments

Chemcial Composition

|

Grade

|

Chemical Composition (<%)

|

|

|

|

|

|

|

|

|

||||||||

|

|

Ti

|

Al

|

V

|

Fe

|

C

|

N

|

H

|

O

|

Other Max

|

||||||||

|

Gr1

|

Blance

|

---

|

---

|

0.2

|

0.08

|

0.03

|

0.01

|

0.18

|

0.4

|

||||||||

|

Gr2

|

Blance

|

---

|

---

|

0.3

|

0.08

|

0.03

|

0.01

|

0.25

|

0.4

|

||||||||

|

Gr3

|

Blance

|

---

|

---

|

0.3

|

0.08

|

0.05

|

0.01

|

0.35

|

0.4

|

||||||||

|

Gr4

|

Blance

|

---

|

---

|

0.5

|

0.08

|

0.05

|

0.01

|

0.4

|

0.4

|

||||||||

|

Gr5

|

Blance

|

5.5-6.75

|

3.5-4.5

|

0.4

|

0.08

|

0.05

|

0.01

|

0.2

|

0.4

|

||||||||

|

Gr7

|

Blance

|

---

|

---

|

0.3

|

0.08

|

0.03

|

0.01

|

0.25

|

0.4

|

||||||||

|

Gr9

|

Blance

|

2.5-3.5

|

2.0-3.0

|

0.25

|

0.08

|

0.03

|

0.01

|

0.15

|

0.4

|

||||||||

|

Gr12

|

Blance

|

---

|

---

|

0.3

|

0.08

|

0.03

|

0.01

|

0.25

|

0.4

|

||||||||

|

Grade

|

Tensil strength (min)

|

|

Yeild strength (min)

|

|

Elongation (%)

|

||

|

|

KSi

|

MPa

|

KSi

|

MPa

|

|

||

|

Gr1

|

35

|

240

|

20

|

138

|

24

|

||

|

Gr2

|

50

|

345

|

40

|

275

|

20

|

||

|

Gr3

|

65

|

450

|

55

|

380

|

18

|

||

|

Gr4

|

80

|

550

|

70

|

483

|

15

|

||

|

Gr5

|

130

|

895

|

120

|

828

|

10

|

||

|

Gr7

|

50

|

345

|

40

|

275

|

20

|

||

|

Gr9

|

90

|

620

|

70

|

438

|

15

|

||

|

Gr12

|

70

|

438

|

50

|

345

|

10

|

||

Packaging & Delivery

1. In spool and plywooden box

2. In coil and woven belt

2. In coil and woven belt

Hot Searches