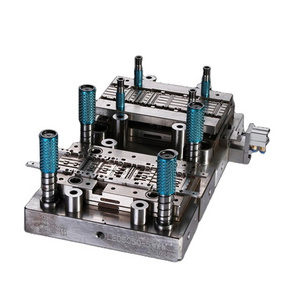

- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

Mold Punch

-

Material:

-

Metal

-

Application:

-

hinge mold

-

Mould Life:

-

20 years stamping experience

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Size:

-

According to your drawing or our existing parts

-

Tolerances/Flatness:

-

0.02mm/0.05mm

-

Packing:

-

Carton

-

Sample:

-

Available

-

Type:

-

Mold Tool

Quick Details

-

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Futuer

-

Product Name:

-

Mold Punch

-

Material:

-

Metal

-

Application:

-

hinge mold

-

Mould Life:

-

20 years stamping experience

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Size:

-

According to your drawing or our existing parts

-

Tolerances/Flatness:

-

0.02mm/0.05mm

-

Packing:

-

Carton

-

Sample:

-

Available

-

Type:

-

Mold Tool

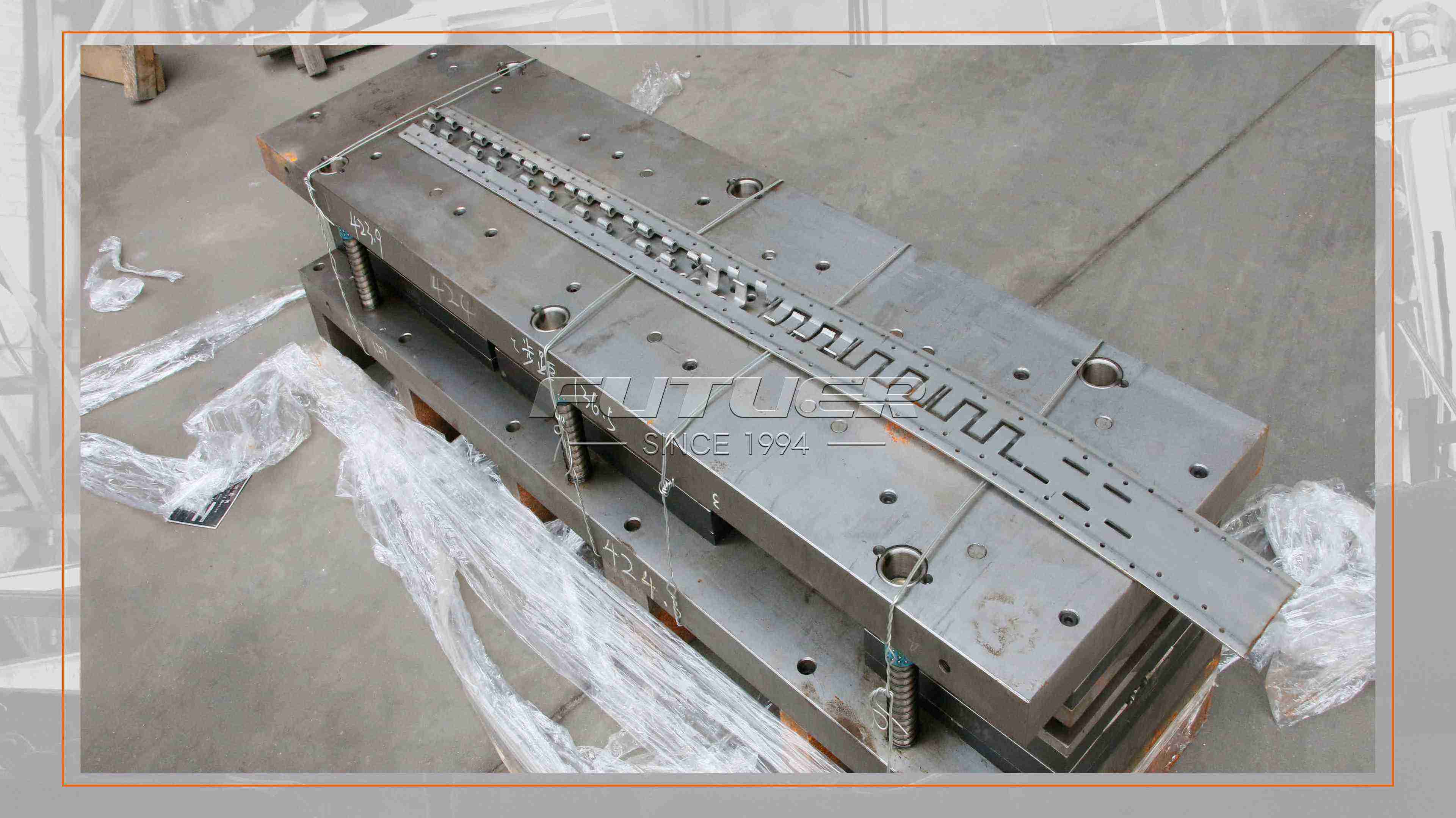

Products Description

production size

Mould Performance and Features

1) Equipment: We own Stamping machines, Hydraulic press machines, Auto-Turning machines, CNC-Turning machines, Milling

machines,Precision wire cutting machines, more than 160 sets in total;

2) Material: iron, carbon steel, stainless steel, brass, copper, alloy steel, aluminum, cold rolled steel with various plating;

3) Surface treatment: kinds of plating (Zinc, Nikel, Chrome, Tin, Ag); Painting, Powder, Anodizing, E-coating, Silkscreen, Heat

treatment, Black oxid;

4) Standard/ specification: OEM service as per customers' requests, within-house tooling design & fabricating;

5) RoHS compliance for export;

6) Quality assurance in accordance with ISO9001:2008;

7) Concurrent engineering capability on product design;

8) Just-in-time manufacturing capability to meet customer's requirement;

9) Tailor-made packaging method according to customer's requirement.

1) Equipment: We own Stamping machines, Hydraulic press machines, Auto-Turning machines, CNC-Turning machines, Milling

machines,Precision wire cutting machines, more than 160 sets in total;

2) Material: iron, carbon steel, stainless steel, brass, copper, alloy steel, aluminum, cold rolled steel with various plating;

3) Surface treatment: kinds of plating (Zinc, Nikel, Chrome, Tin, Ag); Painting, Powder, Anodizing, E-coating, Silkscreen, Heat

treatment, Black oxid;

4) Standard/ specification: OEM service as per customers' requests, within-house tooling design & fabricating;

5) RoHS compliance for export;

6) Quality assurance in accordance with ISO9001:2008;

7) Concurrent engineering capability on product design;

8) Just-in-time manufacturing capability to meet customer's requirement;

9) Tailor-made packaging method according to customer's requirement.

|

Brand Name

|

OEM

|

|

Product Name

|

Metal Stamping Die/Mould

|

|

Tolerance

|

±0.002mm

|

|

Material

|

SKD11, SKD 61, Cr12MOV, D2, SKH-9, RM56, ASP23 etc.

|

|

Design Software

|

AutoCAD, Solid works, PRO/E, UG

|

|

Standard

|

ISO9001

|

|

Mould Type

|

Compound Stamping Die, Single Stamping Die, Progressive die or according to Customer’s requirements

|

|

First Trial

|

15-25 days after mold drawing confirmed

|

|

Mould Life

|

Depends on customer’s production capacity

|

|

|

|

|

|

|

|

Quality confirm

|

Can send strip layout of die, testing video, inspection certificate and sample of product

|

|

Package

|

PE bags and carton for products, wooden case for Die/mold, or as customer's requirements

|

Details Images

Hot Searches