5. The equipment is used in the praduction line to produce 24 hours a day, requiring a low fallure rate and adapingto the needs oflarge-scale production.

6. Power supply: three-phase 380V.

7. Compressed air pressure and flow: 0.4-0.6MPa.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

TKM

-

Power (kW):

-

6.8

-

Weight (KG):

-

850

-

Bending Radius (mm):

-

12 - 500/customized

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

tube end forming machine

-

Color:

-

as your requirements

-

Voltage:

-

220V/380V/415V/440V/customized

-

Material:

-

Stainess Steel

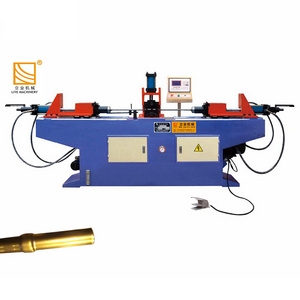

Quick Details

-

Max.Shrinking Capacity (Thickness)(mm):

-

12 mm

-

Max.Shrinking Capacity (Diameter)(mm):

-

12 mm

-

Tube Contracting Cycle (s):

-

35 - 400

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

TKM

-

Power (kW):

-

6.8

-

Weight (KG):

-

850

-

Bending Radius (mm):

-

12 - 500/customized

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

tube end forming machine

-

Color:

-

as your requirements

-

Voltage:

-

220V/380V/415V/440V/customized

-

Material:

-

Stainess Steel

Recommend Products

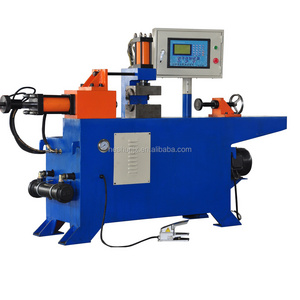

Products Description

Products Description:

1. The equipment adopts the method of hydraulically rotating the bell mouth.

2. The punch has an automatic blowing device.

3. Production beat 3S/piece.

4. The pasitioning of the workpiece adopts a pneumatic structure, and the backing mechanism is adjustable, and thepositioning is stable to ensure the accuracy of repeated positioning.

Product Paramenters

1. This equipment is used to cold-punch and process the pipe ends of metal pipes, such as: bellmouth, flaring, necking and other hydraulic clamping mechanisms, and three-station cold-punching.

2. Manual loading and unloading, automatic processing.

3. lt can also be equipped with automaic loading and unloading device to realize fully automaticproduction.

4. Vertical layout of punches.

5. Optional sawing function.

Customer testimonials

Hot Searches