Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

5000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YUANDA

-

Year:

-

2023

-

Voltage:

-

380V, 60Hz/ 3PH or special order

-

Dimension(L*W*H):

-

2450*1250*1850(mm)

-

Weight (KG):

-

3800 KG

-

Warranty:

-

1Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Automatic:

-

Yes

-

Name:

-

YD-900 plastic oil bottle making machine for production line

-

Suitable bottle:

-

Oil Bottle

-

Advantages:

-

Easy Operation

-

Air cylinder:

-

Festo,smc,airtac

-

Solenoid valve:

-

Festo,smc,airtac

-

Controlled system:

-

PLC & touch screen

-

After Warranty Service:

-

Online Support + Spare Parts

-

Function:

-

Pet Bottle Blow Making Machine

Quick Details

-

Neck Diameter(mm):

-

45 mm

-

Max.Bottle Diameter(mm):

-

300 mm

-

Max.Bottle Height(mm):

-

400 mm

-

Bottle Volume(ml):

-

5000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YUANDA

-

Year:

-

2023

-

Voltage:

-

380V, 60Hz/ 3PH or special order

-

Dimension(L*W*H):

-

2450*1250*1850(mm)

-

Weight (KG):

-

3800 KG

-

Warranty:

-

1Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Automatic:

-

Yes

-

Name:

-

YD-900 plastic oil bottle making machine for production line

-

Suitable bottle:

-

Oil Bottle

-

Advantages:

-

Easy Operation

-

Air cylinder:

-

Festo,smc,airtac

-

Solenoid valve:

-

Festo,smc,airtac

-

Controlled system:

-

PLC & touch screen

-

After Warranty Service:

-

Online Support + Spare Parts

-

Function:

-

Pet Bottle Blow Making Machine

YD-900

Plastic Oil Bottle Making Machine For Peoduction Line

- Produce bottle from 1L to 5L (1cavity)

- Output capacity up to 500-800bph

- Advanced PLC control system with a use-friendly panel and time control precision of PLC up to 0.01second

- Equipped with special designed air storage unit

- Adopt to far infrared preform heater, average and enough heating

- Heating lamps are adjustable in directions to suit various preforms

- Independent temperature control for different heating lamp to get ideal preform heating results

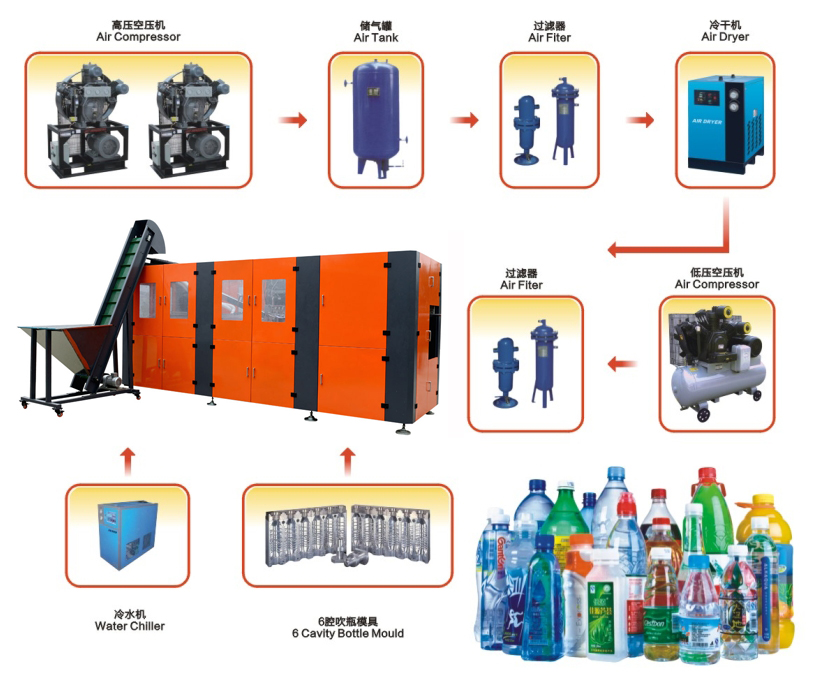

1. High pressure air compressor

| Model no. |

Air discharge (m³/min) |

Dischaege pressure (Mpa) |

Motor power (kw) |

Weight (kg) |

Size(L*W*H)MM |

| 09wm | 3.2 | 3.0 | 15*2 | 1090 | 1900*1700*950 |

2.Low pressure air compressor

| Model no. |

Air discharge (m³min) |

Discharge pressure (Mpa) |

Motor power (kw) |

Weight (Kg) |

Size(L*W*H)MM |

| 09w-1.6/10 | 1.6 | 1.0 | 15 | 680 | 1800*860*1600 |

3.Air tank

| Model no. | Max temperature |

Pressures (Mpa) |

Volume (m³) |

Weigh (kg) |

Size(L*W*H)MM |

| 11-2839 | 150 | 3.2 | 0.6 | 260 | 1050*650*1100 |

4.Air cooling dryer

| Model no. |

Capacity (m³) |

Pressure (Mpa) |

Temperaure (°C) |

Weight (kg) |

Size(L*W*H)MM |

| 3-3 | 3.0 | 3.2 | 2-10°C | 150 | 1200*700*1250 |

5.Mould chiller

| Model no. | Max film |

Compressure (HP) |

Water tank (L) |

Weight (kg) |

Refrigerant | Size(L*W*H)MM |

| JCWC-5HP | 120L/min | 5 | 55 | 60 | R22 | 960*650*1000 |

6. Air filter

| Model no. |

Capacity (m³) |

Pressure (Mpa) |

Temperature (°C) |

Weight (kg) |

Size(L*W*H)MM |

| 3.0 | 3.2 | 1-100°C | 20 | 30*30*60 |

|

General Information |

YD-900 1-cavity |

|

Clamping Force |

30 T |

|

Clamping Stoke |

350mm |

|

Max.Stretching Stroke |

420mm |

|

Bottom Moving Stroke |

0-50mm |

|

Number of Cavities |

1 Cavity |

|

Theoretical Output |

1-6.0L:500-800 BPH |

|

Max.Mould Thickness |

400mm |

|

Mould plate size |

630x340mm |

|

Total Power(Full Loaded) |

10-25KW |

|

Min air compressor |

1.6m 3 /min 3.0Mpa |

|

Min air compressor |

1.2m 3 /min 1.0Mpa |

|

Electrical System |

|

|

Voltage Standard |

380v/3PH/50Hz or special order |

|

Number of Heating Zone |

2 Sections |

|

Total Power(Full Loaded) |

28KW |

|

Container |

|

|

Container Volume |

1.0-6.0L |

|

Neck Diameter Range |

38-60mm |

|

Container Diameter |

300mm |

|

Container Height |

400mm |

|

Air system |

|

|

Low Air compessor |

8-10Bar |

|

High Air compessor |

30-40Bar |

|

Net dimension & Weight(LxWxH) |

|

|

Blow Molding Machine |

235x160x190cm |

|

Preform Autoloader |

270x220x220cm |

|

Net Weight |

3.5T |

Q: Are you a factory or trading company ?

A: We are factory .

Q: How long the warranty period ?

A: All of products have one year warranty .

Q: What is your delivery time and payment term ?

A: About 30 days after payment ,the payment term is 30% as deposit and 70% should pay before shipment .

Q: How about the quality of machine ?

A: Yuanda have been focusing on quality issues ,quality control from beginning to the end ,and we will test machine strictly before packing and delivery .

Q: Can we visit your factory ?

A: Yes, you are welcome to visit our factory .

Q: Where is your factory located , how do we get there ?

A: We are in NO.32 huachang road shidaren industry zone ,Huangyan district ,Taizhou city , Zhejiang province ,China .

You can by air to Luqiao airport and then we will go to pick you .

Pre-sale service After-sale service

Inquiry and consulting support Training how to instal and use the machine

Sample testing support Engineer available to service machinery overseas

View our factory