- Product Details

- {{item.text}}

Quick Details

-

Applicable Material:

-

candy/gummy

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

URBAN

-

Voltage:

-

110-220V 50HZ-60HZ

-

Dimension(L*W*H):

-

44x37x58cm

-

Weight (KG):

-

20

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Production Capacity:

-

1000-2000

-

Power:

-

100KW

-

Weight:

-

50KG

-

Type:

-

Counter Machine

-

After-sales:

-

Service Machinery Overseas

Quick Details

-

Capacity (bottle/min):

-

1200 - 2400 bottle/min

-

Bottle Capacity (pcs/bottle):

-

30 - 150 pcs/bottle

-

Capacity (pcs/h):

-

9000 pcs/h

-

Applicable Material:

-

candy/gummy

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

URBAN

-

Voltage:

-

110-220V 50HZ-60HZ

-

Dimension(L*W*H):

-

44x37x58cm

-

Weight (KG):

-

20

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Production Capacity:

-

1000-2000

-

Power:

-

100KW

-

Weight:

-

50KG

-

Type:

-

Counter Machine

-

After-sales:

-

Service Machinery Overseas

Products Description

|

Model

|

YL-2

|

YL-4

|

YL-2A

|

|

Dimension

|

81x72x84cm

|

98x79x93cm

|

44x37x58cm

|

|

Voltage

|

110-220V 50HZ-60HZ

|

110-220V 50HZ-60HZ

|

110-220V 50HZ-60HZ

|

|

Weight

|

50kg

|

75kg

|

20kg

|

|

Power

|

100KW

|

100KW

|

100KW

|

|

Output

|

1000-2000

|

2000-4000

|

500-1000

|

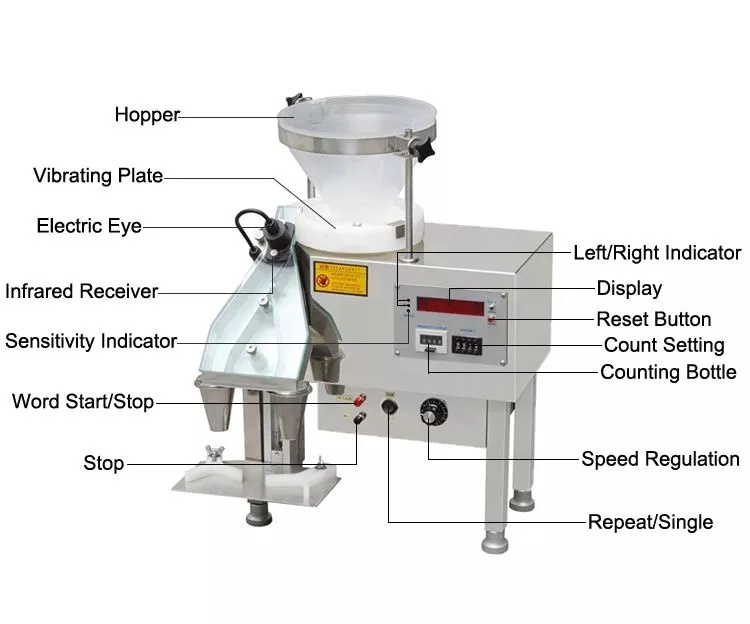

Feature

1. The number of particles can be set arbitrarily from 1-9999.

2. Vibrating feeding and rotary cutting design, the feeding speed can be adjusted infinitely for manual bottle placement.

3. The inside of the machine is equipped with a dust suction channel, which can be connected to a vacuum cleaner to absorb dust.

4. Photoelectric sensing technology, the particle precision is over 99.7%.

5. No need to change the mold, the gummy can be adjusted at will.

6. GMP compliant.

2. Vibrating feeding and rotary cutting design, the feeding speed can be adjusted infinitely for manual bottle placement.

3. The inside of the machine is equipped with a dust suction channel, which can be connected to a vacuum cleaner to absorb dust.

4. Photoelectric sensing technology, the particle precision is over 99.7%.

5. No need to change the mold, the gummy can be adjusted at will.

6. GMP compliant.

Operating Steps

1. Check the disc to make sure there are no gummy or other debris.

2. Pour the gummy into the disc, make sure not too full.

3. The feed opening set into a plastic bag.

4. Adjust the height of the lift plate.

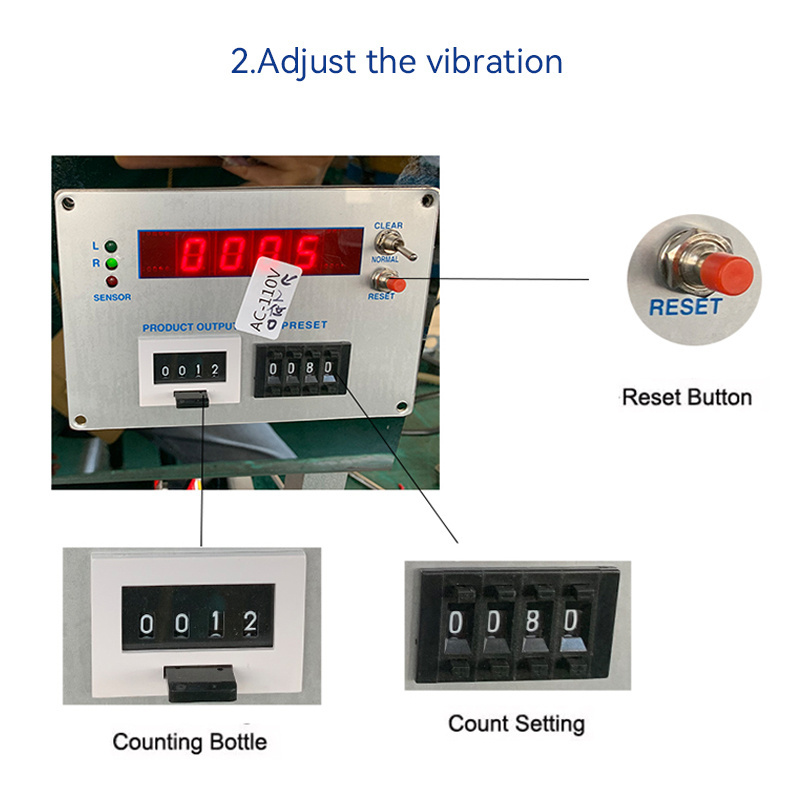

5. Turn on the power; check whether display of detection sensitivity (sensitivity adjustment refer to Troubleshooting).

6. Set number, such as inventory is set in 1000 or more.

7. Return to zero.

8. Turn vibration switch, adjust vibration, note whether gummy on the disc are one by one ordered, and not overlapped.

9. When the counting is finished, it will automatically count the other side.

10. Please note that whether sensitivity indicator flashes normally in operation, and do sampling often; if abnormal should

immediately stop the machine.

11. When operating please make sure not so many gummy are poured into the disc, so that they are not overlapped and wrong counted.

12. Avoid placing the machine near the windows, outdoors, or in the sun.

2. Pour the gummy into the disc, make sure not too full.

3. The feed opening set into a plastic bag.

4. Adjust the height of the lift plate.

5. Turn on the power; check whether display of detection sensitivity (sensitivity adjustment refer to Troubleshooting).

6. Set number, such as inventory is set in 1000 or more.

7. Return to zero.

8. Turn vibration switch, adjust vibration, note whether gummy on the disc are one by one ordered, and not overlapped.

9. When the counting is finished, it will automatically count the other side.

10. Please note that whether sensitivity indicator flashes normally in operation, and do sampling often; if abnormal should

immediately stop the machine.

11. When operating please make sure not so many gummy are poured into the disc, so that they are not overlapped and wrong counted.

12. Avoid placing the machine near the windows, outdoors, or in the sun.

Hot Searches