- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LONGSN

-

Weight:

-

540 KG

-

Dimension(L*W*H):

-

by order

-

Product name:

-

cap inserting wadding machine

-

Material:

-

Stainless steel

-

Suitable for:

-

plastic lid

-

Capacity:

-

3000-18000pc/h

-

Certificate:

-

CE ISO certification

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Function:

-

Insert liner into cap

-

Feature::

-

Accurate

-

Advantage:

-

High Packing Speed

-

Customized support:

-

OEM

-

Marketing Type:

-

New Product 2020

Quick Details

-

Voltage:

-

220V/Customized

-

Power:

-

0.5KW

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LONGSN

-

Weight:

-

540 KG

-

Dimension(L*W*H):

-

by order

-

Product name:

-

cap inserting wadding machine

-

Material:

-

Stainless steel

-

Suitable for:

-

plastic lid

-

Capacity:

-

3000-18000pc/h

-

Certificate:

-

CE ISO certification

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Function:

-

Insert liner into cap

-

Feature::

-

Accurate

-

Advantage:

-

High Packing Speed

-

Customized support:

-

OEM

-

Marketing Type:

-

New Product 2020

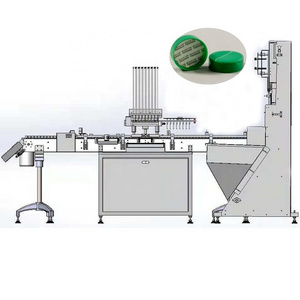

China leading manufacturer Automatic butterfly cap closing machine cap wad inserting machine

China leading manufacturer Automatic butterfly cap closing machine cap wad inserting machine

Longsn Automatic cap wadding liner inserting machine is an ideal inserting machine which replaces the traditional manual operation, it can punch the liner to some mode and then finish capping to avoid the manual pollution and improve the product efficiency as well. It is mainly applied to cosmetic, food, beverage, medicine and other fields.

Equipment structure constitutes:

The automatic covers neatens organization: arranging in great disorder bottle cover to the exportation,and making all upward covers. The bottle cover transports organization:

having the reason good bottle cover preface,transporting them to the filling gaskets organization accurately. The filling gaskets organization:

filling gaskets into the covers and check-up,then get rid of waster .

Attach mechanism:

bad products will automatic remove,like reverse side,no shim.

Equipment characteristics:

PLC control by mitsubshi,touch screen is HIM,bad product will automatic remove,automatic count,automatic alarm and stop

1) substitution of handicraft,the gaskets go into a bottle of cover automatically

2) pressurizing gaskets completely reasonably,quickly,efficiently,and the safe and hygiene products

3) suiting the usage situation which requests the hygiene condition specially,avoiding second pollution to the material,economizing a disinfectant craft

4) transporting the covers and accurate orientation system

5) neatening the cover organization can get rid of waster ,and all covers head up

6) the whole machine adopts PLC controls,reports to the police without the bottle cover or gaskets

7)auto count function,chooseing the suit gaskets to cover,getting rid of waster having no gaskets inside after filling gaskets into the cover

Technical parameter:

|

Model

|

LSN-L2

|

|

Speed

|

3000-18000pc/h

|

|

Size

|

2500*1850*1800mm

|

| Air pressure |

5-7kgf/m2

|

|

Weight

|

540kg

|

|

Power

|

220V 50-60Hz

|

Before the order:

We will make detailed solution for you based on your requirments.

We will send you videos of our products to know more about our machines.

If you are willing to visit our factory,we will pick you up at a nearby airport/station.

After the order:

We will start to produce machines and update the progress.

Our engineer will draw the layout for you.

After-sales service:

Arrange our engineer to your factory to install machines if you need,train your employee until they can operate machines well.

Provide you 2 years warranty with spare parts 2 year free.

24 hours for engineer response (all services part 5days in customer hand by Intl' courier)