- Product Details

- {{item.text}}

Quick Details

-

Type:

-

vegetable processing machinery

-

Voltage:

-

customize

-

Power:

-

customize

-

Weight:

-

12000 KG

-

Dimension(L*W*H):

-

18000X11000X5000MM

-

Year:

-

2023

-

Application:

-

Fruit Vegetable

-

Product name:

-

Fruit Dehydrator Machine Fruit

-

Material:

-

Stainless Steel 304

-

Key words:

-

fruit Drying Plant

-

Final product:

-

Powder

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Raw material:

-

fruit vegetable

-

Capacity:

-

500-1000kg/h

-

After Warranty Service:

-

Lifelong Technical Support

-

Brand:

-

Antler

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Anlter

-

Type:

-

vegetable processing machinery

-

Voltage:

-

customize

-

Power:

-

customize

-

Weight:

-

12000 KG

-

Dimension(L*W*H):

-

18000X11000X5000MM

-

Year:

-

2023

-

Application:

-

Fruit Vegetable

-

Product name:

-

Fruit Dehydrator Machine Fruit

-

Material:

-

Stainless Steel 304

-

Key words:

-

fruit Drying Plant

-

Final product:

-

Powder

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Raw material:

-

fruit vegetable

-

Capacity:

-

500-1000kg/h

-

After Warranty Service:

-

Lifelong Technical Support

-

Brand:

-

Antler

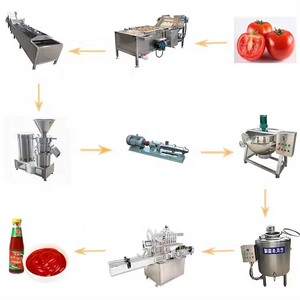

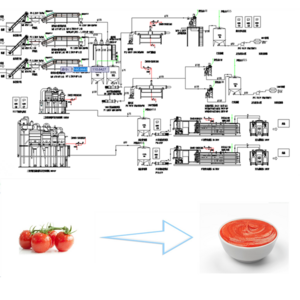

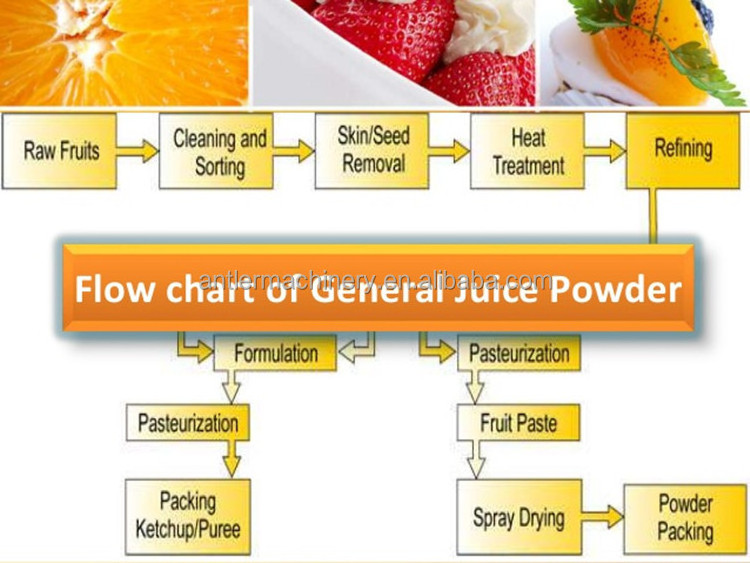

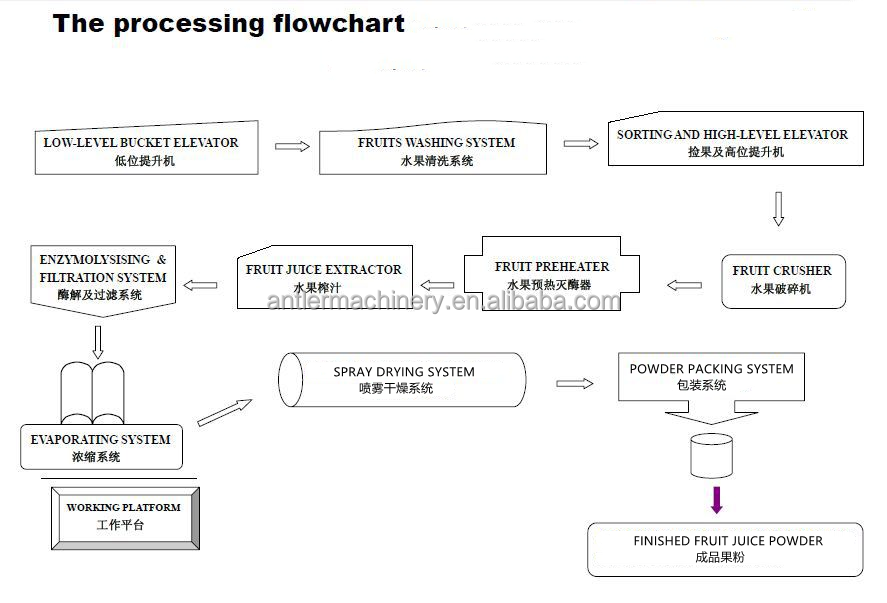

Product Overview

Fruit and vegetable processing machine start with washing , peeling, pulping for liquidize the fruit or vegetables with enzyme and filtration machine to have the clear juice. equip with vacuum evaporation and spray drying system to have the instant fruit powder. After filtering and heating, the air enters into air distributor on top of the Drying Equipment. The hot air enters into the drying tower spiral form and uniformly. By .passing through high-speed centrifugal atomizer on top of tower, the material liquid will rotate and be sprayed into the extremely fine mist liquid beads. Through the very short time of contacting with heating air, the material can be dried into final products. The final products will be discharged continuously from the bottom of drying tower and from cyclone separator.The waste gas will be discharged from exhaust fan. The production procedures are simple and the operation and control are easy.The liquid with the moisture contents 40-60% (for special materials, the contents may reach 90%) can be dried into the powder of particle products for one time. After drying, there is no need for crushing and sieving, so as to reduce operation procedures in the production and to enhance product purity. The product particle diameters, looseness and water contents can be adjusted through changing the operation condition in a certain scope. It is very convenient to carry out control and management.

Specification

|

Type

|

|

Juice Dryer

|

|

|

|||

|

Application

|

|

Fruit / vegetable

|

|

|

|||

|

Final products

|

|

Instant Powder

|

|

|

|||

|

Heating source

|

|

steam

|

|

|

|||

|

Brand

|

|

Antler

|

|

|

|||

|

Warranty

|

|

2years

|

|

|

|||

Recommend products

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Certifications

Packing & Delivery

Hot Searches